Twin City Fans With CE Mark - ES-2-06 User Manual

Page 8

8.

Twin.City.Fan.Engineering.Supplement.2-06

Grouting

Grouting. is. the. final. installation. step.. Check. all. shims.

before. grouting. to. make. sure. that. the. fan. is. resting.

evenly.on.all.points.with.anchor.bolts.secured.to.hold.

the. shim.. Use. forms. with. sufficient. space. allowed. for.

working. the. grout.. The. concrete. foundation. should. be.

clean. and. well. moistened. before. pouring. grout.. Use. a.

commercial.grade.non-shrinking.grout.and.be.especially.

sure.when.pouring.grout.that.the.anchor.bolt.sleeves.are.

filled..Refer.to.Figure.2.for.a.detail.of.a.proper.founda-

tion,.grout.allowance.and.anchor.bolt.sleeves.

Drive Mounting

Mount.drives.as.follows:

1..Slip. (do. not. pound). proper. sheave. onto. correspond-

ing.shaft..

CAUTION:.Placing.fan.sheave.on.motor.can.

overspeed.wheel.and.cause.structural.failure.

2..Align. sheaves. with. straightedge. extended. along.

sheaves. (see. Fig.. 5),. just. making. contact. in. two.

places. on. outside. perimeters. of. both. sheaves.. This.

“four-point”. alignment. may. also. be. checked. with. a.

string. tied. to. the. shaft. behind. one. of. the. sheaves..

The.string.is.then.pulled.taut.over.the.faces.of.the.

sheaves. to. check. the. alignment. at. the. four. points.

at. the. outside. perimeters.. Each. sheave. should. be.

rotated. about. one-half. revolution. during. this. check.

to.look.for.excessive.runout.or.a.bent.shaft..Parallel.

alignment.should.be.within.5mm.per.meter.of.center.

distance..Angular.Misalignment.should.be.less.than.1.

degree.

3..Install. and. tighten. the. belts.. Proper. belt. tension. is.

specified. on. the. included. documentation.. Belts. are.

tensioned.as.follows:

Post. type,. saddle. base,. slide. rails,. and. slide. base.

types.use.one.or.more.bolts.held.by.retaining.nuts.to.

adjust.the.motor.position..Loosen.the.retaining.nuts.

and.adjust.the.bolts.to.push.or.pull.the.motor.until.

the. belts. reach. their. specified. tension.. Tighten. the.

retaining.nuts.per.torque.specifications.in.Table.1.

4..Run. the. drive. for. a. few. minutes. to. seat. the. belts..

When.tightening.the.belts,.slide.the.motor.in.to.slip.

the.belts.on..Do.not.use.a.pry.bar,.as.this.may.dam-

age.the.belt.cords..Retighten.the.belts.to.the.proper.

tension.if.necessary..Recheck.sheave.alignment.

5..After. initial. installation. of. belts,. recheck. belt. tension.

and.alignment.as.indicated.in.Table.7.

Flexible Couplings

These. instructions. are. general. for. the. installation. of.

several. types. of. flexible. couplings. and. should. not. be.

used. as. a. substitute. for. more. specific. manufacturer’s.

instructions..The.coupling.manufacturer’s.installation.data.

is.included.with.the.supplied.datasheet.(when.applicable).

and. will. give. specific. dimensions. for. alignment. limits,.

lubricants,.etc..

. Before. preparing. to. mount. the. coupling,. make. sure.

that.all.bearings,.inlet.vanes,.shaft.seals,.or.other.com-

ponents.have.been.installed.on.the.shaft.

. When. mounting. and. keying. the. coupling. halves. to.

the. shaft,. follow. supplied. instructions. for. heating. and.

shrink.fitting..Set.the.coupling.halves.for.the.normal.gap.

specified.by.the.manufacturer..Coupling.gap.is.illustrated.

in.Figure.6.

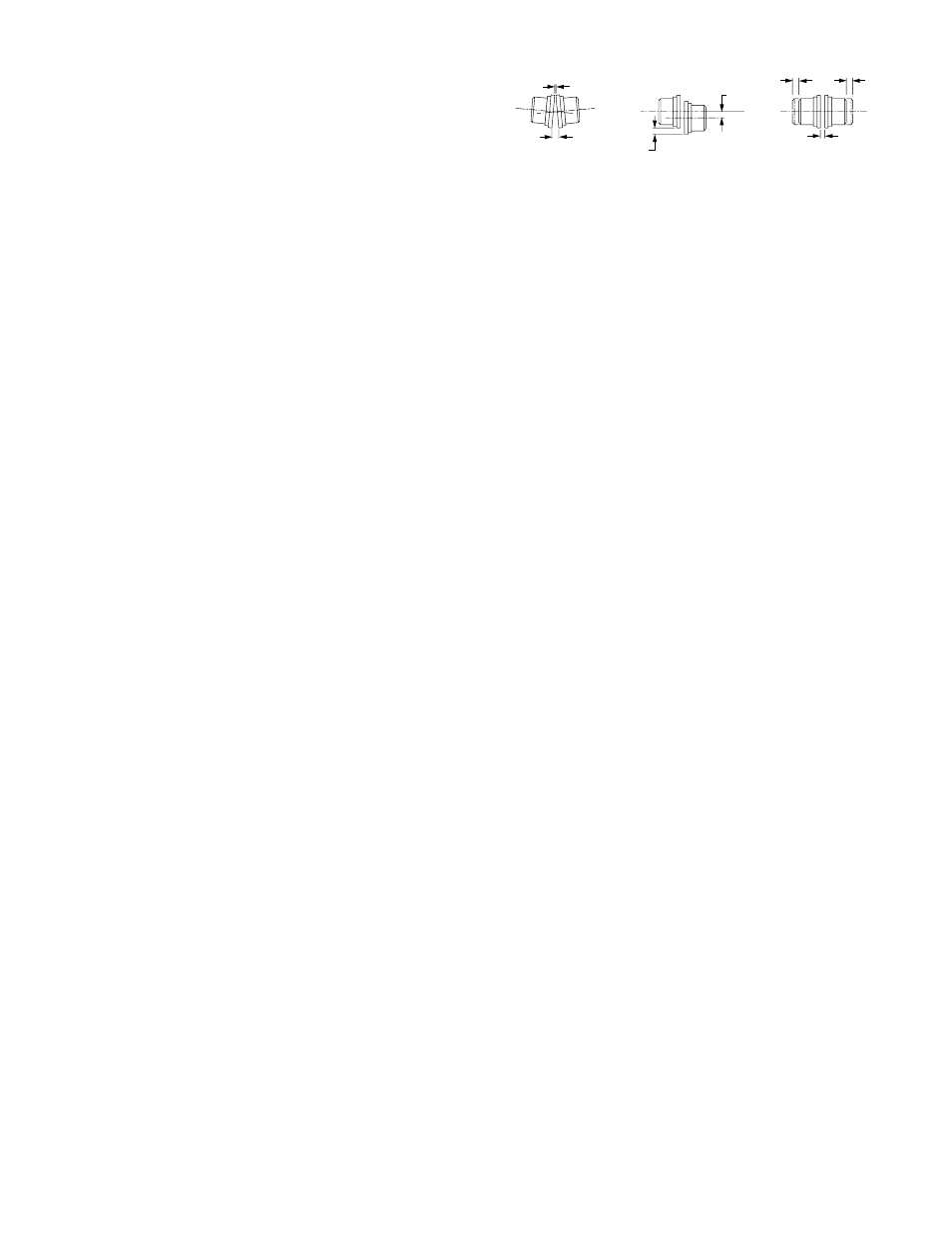

. The.two.types.of.misalignment.are.illustrated.above..

Typically.angular.alignment.is.checked.with.feeler.gaug-

es.between.the.hub.faces..When.angular.alignment.has.

been. adjusted. to. manufacturer’s. specification. by. shim-

ming,. if. necessary,. parallel. alignment. can. be. checked.

with.a.straightedge.and.feeler.gauges.on.the.hub.halves’.

O.D.. When. shimming. has. brought. parallel. alignment.

within. specification,. angular. alignment. and. gap. should.

again.be.checked,.and.adjustments.made.if.necessary..

A. dial. indicator. may. be. used. to. more. accurately. take.

the.measurements.described.above.

. Special.adjustments.may.need.to.be.made.for.cou-

plings.used.with.some.equipment..As.an.example,.when.

used.with.motors.of.over.300.HP,.couplings.may.require.

provisions.for.limiting.end.float..Larger.drivers.may.grow.

in.operation.(due.to.heat.expansion).requiring.the.driver.

side.to.be.set.slightly.low.when.not.operating..Specific.

instruction. manuals. or. assembly. drawings. will. indicate.

these.requirements.when.applicable.

. Thoroughly.clean.the.coupling.halves.after.completion.

of.alignment..Reassemble.the.coupling.and.tighten.bolts,.

washers.and.locknuts..Lubricate.per.manufacturer’s.rec-

ommendations.

Duct Connections

The. fan. support. structure. is. normally. not. designed. to.

carry.loads.imposed.by.the.weight.of.ducts,.silencers,.

stacks,. etc.. Supporting. these. loads. on. the. fan. can.

cause. housing. distortion. and. may. cause. performance.

problems. due. to. the. relation. of. fan. housing. to. wheel..

Use.of.flexible.connections.is.recommended.

. Where. hazardous. materials. will. be. conveyed. in. the.

fan,. all. connections. made. by. the. user. shall. be. com-

pletely.sealed.with.material.suitable.for.the.gas.or.vapor.

to.be.handled.

Guards and Enclosures

When. advised. of. the. need. for. guards. fully. complying.

with.the.machinery.directive,.Twin.City.Fan.Companies,.

Ltd..will.supply.the.guarding.identified.as.being.required..

In. most. cases,. Twin. City. Fan. Companies,. Ltd.. is. not.

aware.of.the.end.use.and.installation.of.the.fan,.which.

typically.eliminates.the.need.for.more.restrictive.guard-

ing.to.be.compliant.with.EN.294.and.EN.811..For.this.

reason,.the.user.is.must.verify.that.the.final.installation.

is.compliant.with.EN.953,.EN.294,.and.EN.811..This.is.

especially.true.of.plug.and.plenum.fans..Specific.items.

that. should. be. considered. include. but. are. not. limited.

to.the.following:

•. Outlet ducting / enclosure..The.ducting.or.enclosure.

must.be.compliant.to.the.requirements.of.EN.953.

and.EN.294.and.EN.811..This.is.not.assured.by.

Twin.City.Fan.Companies,.Ltd..unless.specifically.

notified.by.the.end.user.at.the.time.of.the.order.

•. Inlet guards..Inlet.guarding.relies.on.the.additional.

safety.distance.provided.by.inlet.ducting.or.other.

enclosure.increasing.the.safety.distance.to.850.mm.

or.greater..This.is.because.the.installation.usually.

eliminates.the.need.for.excessive.guarding.on.the.

inlet.of.the.fan..In.addition,.excessive.guarding.on.

the. inlet. of. the. fan. would. significantly. deteriorate.

performance.and.is.therefore.not.desirable.

Y

X

P

P

F

F

GAP

.

ANGULAR

PARALLEL

GAP AND

MISALIGNMENT

MISALIGNMENT

END FLOAT

X-Y.=.ANGULAR.MISALIGNMENT

P. =.PARALLEL.OFFSET.(MISALIGNMENT)

F. =.END.FLOAT

Figure 6. Coupling Alignment