Twin City Fans With CE Mark - ES-2-06 User Manual

Page 16

blades.are.set.at.the.same.mark.

5..After.all.blades.are.set.at.a.new.angle,.run.the.fan.for.

a.few.minutes.and.then.re-torque.all.blade.bolts.

Blade Adjustment on Aerovent Reversible

Adjustable Pitch Propeller

Assembly Procedures

1..Lay. hub. on. a. horizontal. surface. with. openings. of.

shank.sockets.(Figure.15).facing.up..This.is.normally.

the.discharge.side.of.the.assembly.

2..Lay.blade.shank.in.socket.with.discharge.side.of.the.

blade.up..The.discharge.side.of.the.blade.is.the.side.

with.the.angle.setting.mark..Line.up.the.index.mark.on.

the.blade.with.the.proper.angle.mark.on.the.end.of.

the.shank.socket.(Figures.14.and.15).on.the.underside.

of.assembly.

3..Place.cap.over.blade.shank.with.beveled.end.toward.

center.. Install. U-bolts. and. elastic. nut. stops.. Before.

tightening. lock. nuts,. pull. the. blade. outward. to. set.

the. key. against. the. keyway. and. check. angle. setting.

(Figures.14.and.15).

4..Tighten.elastic.stop.nuts.evenly.and.torque.to.the.fol-

lowing.foot-pounds:

5..Check. angle. setting. to. be. sure. it. has. not. changed.

during. assembly.. If. so,. loosen. lock. nuts. and. reset.

angle.. Tighten. nuts. again. to. proper. torque.. Do. not.

over-tighten..Be.sure.to.tighten.U-bolts.evenly.

Setting Angle with Protractor (optional)

Under. most. conditions,. the. preceding. assembly. proce-

dure.using.the.index.marks.is.of.sufficient.accuracy.

. When.greater.accuracy.is.desired,.use.a.level.bubble.

protractor..Before.the.final.tightening.of.the.nuts,.set.the.

protractor.on.the.angle.setting.mark..(The.hub.and.blade.

assembly.must.be.level.for.accurate.setting.)

. Adjust. the. angle. by. tapping. the. shank. end. with. a.

mallet.

. Tighten.lock.nuts.to.proper.torque.per.Table.8..Again.

check.the.angle.setting..Rotate.propeller.to.check.angle.

on.each.blade.in.the.same.location.

. Propellers.may.be.assembled.so.the.cap.side.of.the.

hub.is.the.inlet.side.(reverse.bore)..If.blades.do.not.have.

the.index.mark.on.the.discharge.side,.it.is.then.necessary.

to.adjust.the.blade.angle.with.a.protractor.

. The. hub. and. blades. are. balanced. separately.. The.

weight. distribution. throughout. the. length. of. the. blade.

varies. slightly.. Therefore,. the. balance. is. to. a. constant.

moment.and.blades.may.be.assembled.at.random.even.

though.the.weights.are.slightly.different.

Angle.setting.index.on.shank.socket..Marked.

from.10°.through.50°..Each.mark.is.2°..

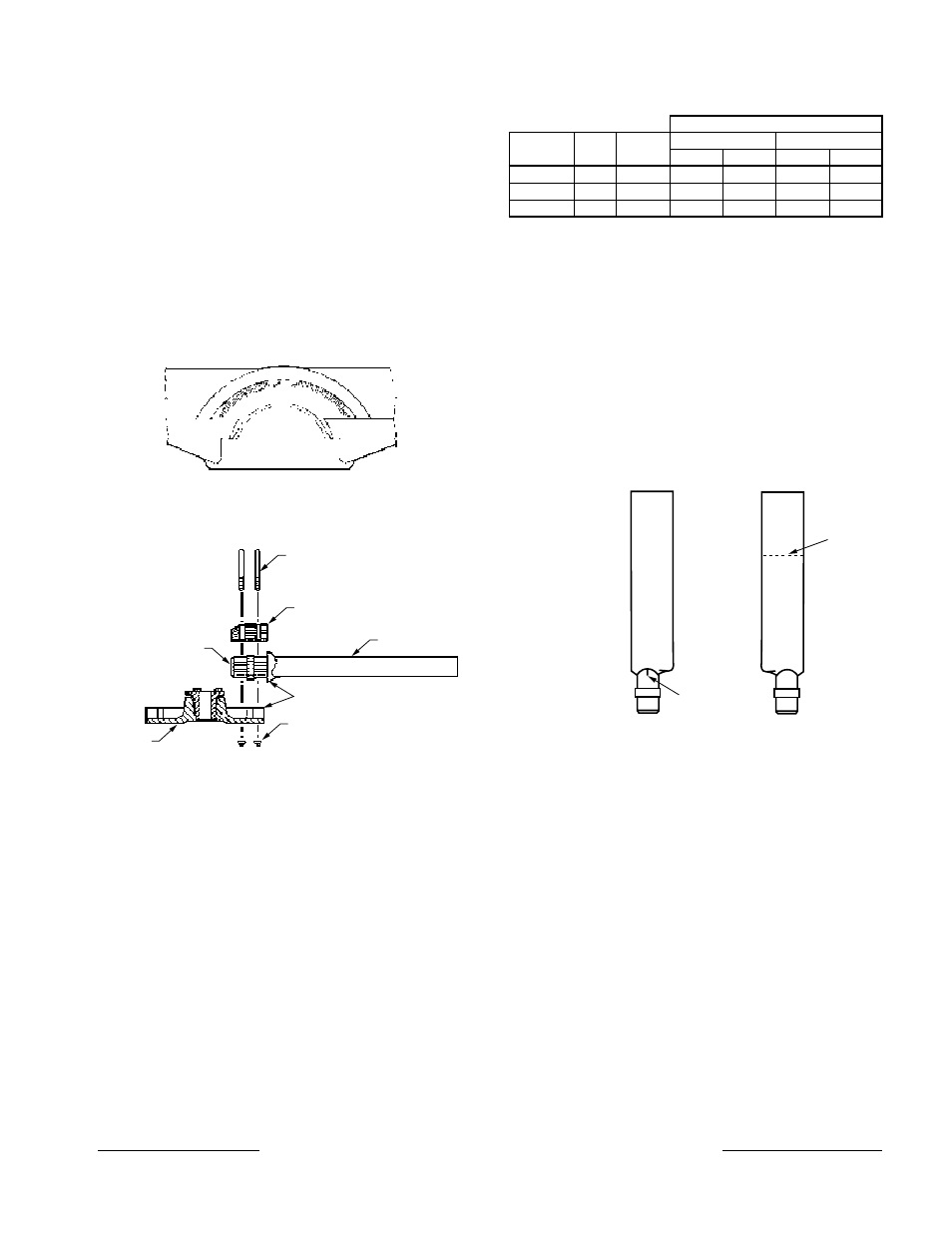

Figure 14. Angle Setting Markings

Elastic Stop Nuts

Index Marks

Blade

U-Bolts

Cap

Blade

Shank

Hub

Figure 15. Assembly Exploded View

Angle

Setting

Mark

Index

Mark

.

Inlet.Side.

Discharge.Side

Figure 16. Blades and Angle Setting Mark

Torque

Prop

Size

Hub

Size

U-Bolt

Size

Aluminum

Fiberglass

Ft-lb

N-m

Ft-lb

N-m

54.-.72

14

1/2”

20

27

30

41

81.-.96

18

3/4”

45

61

50

68

108.-.144

18

3/4”

45

61

50

68

Table 8. U-Bolt Torque for Aerovent Blades

Twin ciTy fan & blower | www.Tcf.com

5959 Trenton Lane N | Minneapolis, MN 55442 | Phone: 763-551-7600 | Fax: 763-551-7601