Twin City Fans With CE Mark - ES-2-06 User Manual

Page 3

3.

Twin.City.Fan.Engineering.Supplement.2-06

sleeve. with. a. diameter. of. 2. to. 21⁄2. times. the. anchor.

bolt.diameter.should.be.provided.around.the.anchor.bolt.

for. final. adjustment. (see. Figure. 2).. The. mounting. sur-

face.of.the.foundation.should.be.smooth.for.good.shim.

contact..When.deciding.the.thickness.of.the.foundation,.

approximately.25.to.40mm.height.should.be.allowed.for.

shimming,.grouting,.leveling,.washers,.nuts,.etc.

. The.foundation.plan.on.the.customer.submittal.draw-

ing. indicates. the. mounting. hole. size. and. locations. on.

the.fan.

.

If.a.structural.steel.base.or.platform.is.to.be.used,.the.

structure. must. be. designed. for. the. weight. of. the. fan,.

live.loads.imposed.by.rotation.of.the.rotor.and.driver,.

and. any. external. live. loads.. The. structure. should. be.

designed.to.ensure.that.no.natural.frequency.will.occur.

within.30%.of.the.fan.speed..This.is.especially.true.if.

the.structure.supports.more.than.one.fan.

. Any. ducting. should. have. independent. support.. Do.

not. use. the. fan. to. support. ducting.. The. fan. frame.

can.be.designed.to.carry.some.external.loads..Consult.

the. factory. if. this. is. a. concern.. Isolating. the. fan. from.

ductwork. with. flex. connections. eliminates. transmission.

of.vibration..Fans.handling.hot.gases.require.expansion.

joints.at.both.the.inlet.and.discharge.to.prevent.exces-

sive. loads. caused. by. thermal. growth.. Refer. to. AMCA.

Publication.201.for.good.practices.in.ductwork.geometry.

and. configuration.. When. possible,. ductwork. shall. be.

located. where. there. is. least. risk. of. personnel. tripping,.

walking.into.or.falling.over.the.ductwork..If.not.possible,.

warnings.shall.identify.this.hazard.

. See. Appendix. A. Commercial. Ventilator. Installation.

Instructions.for.commercial.ventilator.foundation.details.

. Fans.should.not.be.located.underneath.other.machin-

ery.where.there.might.be.a.risk.of.harmful.liquid.falling.

onto.fans.from.above.

. Fans.should.be.installed.where.they.are.readily.acces-

sible.to.maintenance.personnel,.so.that.such.personnel.

are.not.required.to.stoop.or.crawl.to.access.fans.

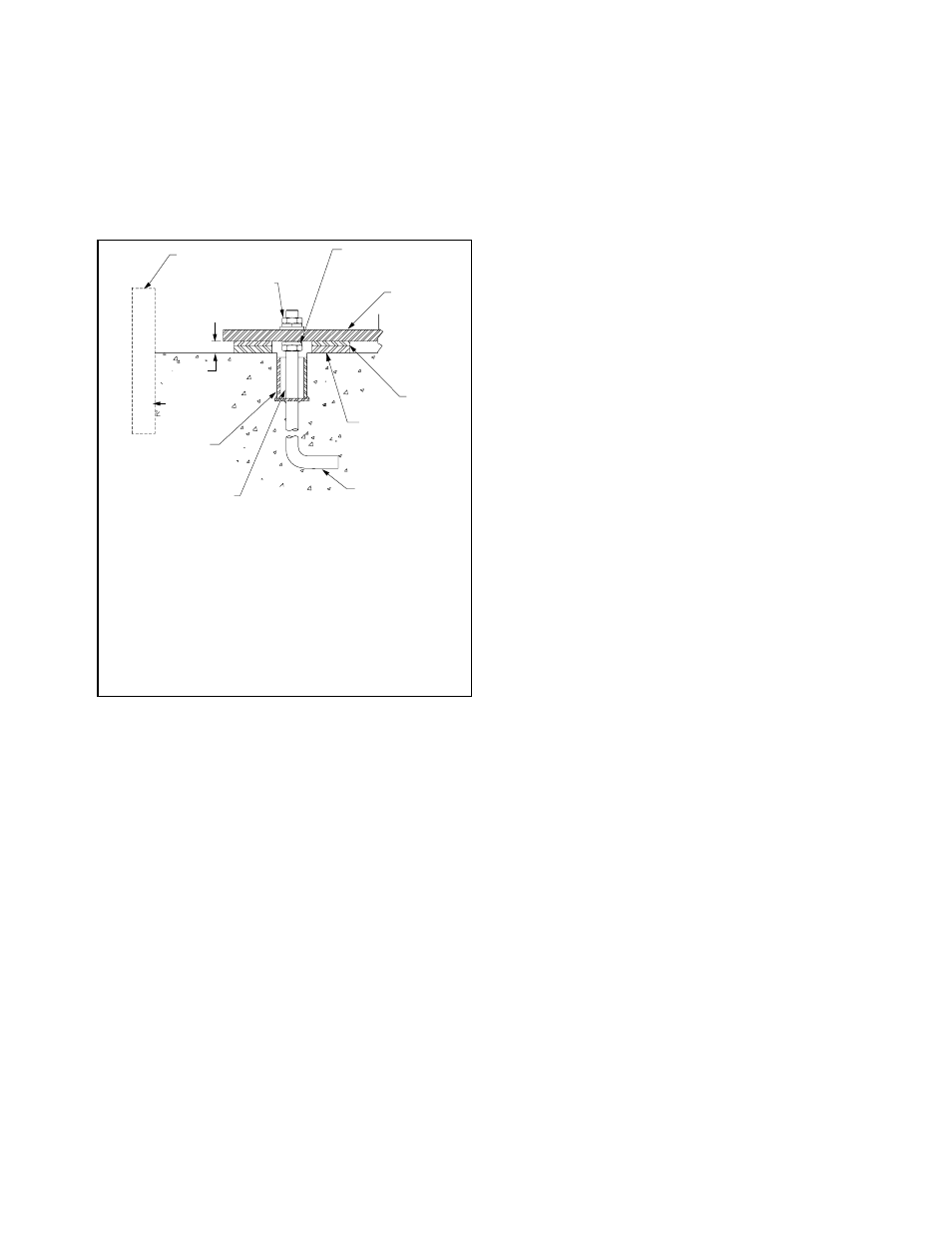

Figure 2. Typical Foundation Section

Fan Installation - Factory Assembled Units

General instructions for industrial centrifugal fans – For Axial

fans and commercial ventilators, follow steps below noting

instructions specific to those fan types in Appendix A and B.

Follow.proper.handling.instructions.as.given.earlier.

.1.. Move.the.fan.to.the.final.mounting.position.

.2.. Remove.skid,.crates.and.packing.materials.carefully.

.3.. If. vibration. isolation. is. to. be. used,. place. isolation.

base.on.mounting.bolts..Line.up.holes.in.fan.base.

with. bolts. as. indicated. on. the. foundation. plan. of.

the.customer.submittal.drawing.

.4.. Consult. each. specific. fan’s. submittal. drawing. for.

proper.installation.arrangement.and.mounting.dimen-

sions..Place.the.fan.on.mounting.structure..Carefully.

level. the. unit. (checking. the. level. on. the. shaft). on.

the.foundation.and.shim.as.necessary.using.stain-

less.steel.shims.on.both.sides.of.each.anchor.bolt..

Anchor.bolts.are.to.be.pre-tensioned.per.Table.1..

For. metric. grade. bolts. or. materials. not. shown. in.

Table.1,.check.with.bolt.manufacturer.for.the.proper.

torque.. (See. details. specific. to. commercial. ventila-

tors.in.appendix.A.for.this.step).

.5.. Check. the. alignment. of. the. bearings.. Shim. or.

reposition. the. bearings. if. necessary.. In. many. split.

housing. roller. bearings,. the. gap. between. the. seal.

carrier.and.housing.can.be.measured.with.a.feeler.

gage..The.variation.in.this.gap.should.be.less.than.

half.of.the.maximum.gap.measured..In.roller.bear-

ings. where. this. gap. is. not. visible,. alignment. can.

be. verified. by. verifying. the. bearing. is. square. with.

the.pedestal.top..In.ball.bearings,.the.bearing.outer.

ring.swivels.in.the.housing.to.accommodate.a.small.

amount.of.misalignment..Verify.bearing.set.screws,.

cap.bolts,.and.collars.are.tightened.per.Tables.2a,.

2b.and.2c.

.6.. Check.face.alignment.of.sheaves.on.belt.driven.fans..

Parallel.alignment.should.be.within.5mm.per.meter.of.

center.distance..Angular.Misalignment.should.be.less.

than. 1. degree.. Check. and. record. tension. of. belts.

to.see.if.it.is.sufficient..Proper.belt.tension.is.speci-

fied.on.the.included.datasheet..If.belt.tension.needs.

adjustment,. instructions. on. belt. tensioning. are. given.

in.the.Drive.Mounting.section.of.this.manual..Sheaves.

on.belt.driven.fans.are.often.provided.with.taperlock.

bushings..When.tightening.bushing.bolts,.proceed.in.a.

progressive.manner.to.avoid.cocking.the.tapered.sur-

faces.between.the.bushing.and.the.sheave..Bushing.

bolt.torque.specifications.are.indicated.in.Table.3.

.7.. Check. alignment. of. factory. mounted. couplings,. as.

they. are. subject. to. misalignment. during. shipment..

Realign.if.necessary.in.accordance.with.the.instruc-

tions.which.are.included.with.the.shipment..

NOTE:

Most.couplings.need.lubrication.

.8.. Make.sure.there.is.no.rubbing.or.binding.and.that.

the.wheel-inlet.cone.or.wheel.to.fan.housing.clear-

ances. and. overlap. are. correct.. Overlap. values. or.

other.dimensions.to.verify.proper.wheel.location.are.

given.in.the.included.documentation.specific.to.the.

fan.. Wheel. clearance. should. be. verified. to. match.

the.specified.value.and.be.uniform..The.measured.

values.should.be.recorded.

.9.. Check.the.tightness.of.the.wheel.on.the.shaft.per.

Table.4..The.measured.torque.should.be.recorded.

10..Check. the. tightness. of. foundation. bolts,. motor.

mounting. bolts,. and. bearing. mounting. bolts. per.

Table.1..For.metric.bolts.or.grades.not.specified.in.

Table. 1,. check. proper. torque. values. per. the. bolt.

manufacture.

NOTES:

1..

Temporary.form.for.grout.pouring.

2..

Hex.nut,.split.ring.lock.washer.and.tapered.or.flat.washer.

3..

1".to.1.5".grout.allowance.to.be.filled.with.nonshrinking.machin-

ery.grout.

4..

Pipe-bolt.sleeve.diameter.2.to.2

1

/

2

.times.bolt.diameter.for.cor-

rection.of.alignment.errors.

5..

Care. should. be. taken. that. anchor. bolt. sleeves. are. filled. with.

grout.

6..

J-Bolt.leg.should.be.fastened.to.foundation.rebar.

7..

Shimming.surface.to.be.smooth,.level,.dressed.if.necessary.

8..

Full.width.stainless.steel.shims.

9..

Fan.base.angle.or.structural.steel.

10.. Leveling.nut,.if.used,.should.be.backed.off.after.shimming.for.

final.tightening.of.hex.nuts.