Twin City Fans With CE Mark - ES-2-06 User Manual

Page 5

5.

Twin.City.Fan.Engineering.Supplement.2-06

10..Mount.drives.as.follows:

.

a..Slip. (do. not. pound). proper. sheave. onto. cor-

responding. shaft.. CAUTION:. PLACING. FAN.

SHEAVE.ON.MOTOR.CAN.OVERSPEED.WHEEL.

AND.CAUSE.STRUCTURAL.FAILURE.

.

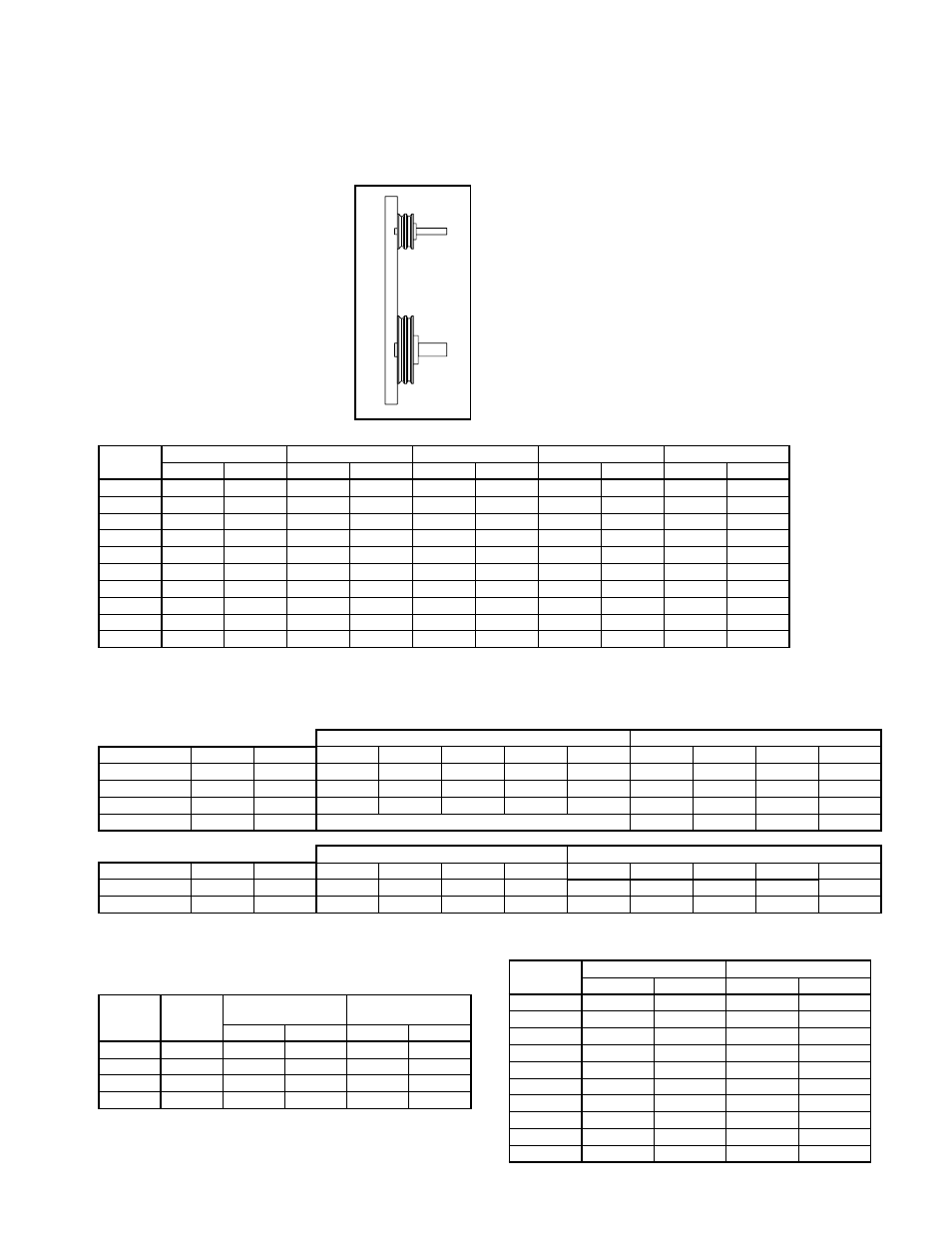

b..Align.sheaves.with.a.straight-

edge. extended. along. the.

perimeters. of. both. sheaves,.

just. making. contact. in. two.

places. on. outside. perimeters.

of. both. sheaves. (see. Figure.

5).. Parallel. alignment. should.

be. within. 5mm. per. meter.

of. center. distance.. Angular.

Misalignment. should. be. less.

than.1.degree.

.

c..Tighten.down.sheave.bolts.

.

d..Install. a. matched. set. of.

belts.. Adjust. belt. tension. as.

indicated.in.“Drive.Mounting”.

step.#3.

Size

Grade 2

Grade 5

Grade 8

Aluminum

Stainless

(Ft - lbs)

(N - m)

(Ft - lbs)

(N - m)

(Ft - lbs)

(N - m)

(Ft - lbs)

(N - m)

(Ft - lbs)

(N - m)

1/4 - 20

5.5

7.5

8

10.8

12

16.3

3.8

5.2

6.3

8.5

5/16 - 18

11

15

17

23

25

34

6.7

9.1

11

15

3/8 - 16

22

30

30

41

45

61

11.9

16

19

26

7/16 - 14

30

41

50

68

70

95

19

26

31

42

1/2 - 13

55

75

75

102

110

149

26

35

43

58

5/8 - 11

100

136

150

203

220

298

59

80

92

125

3/4 - 10

170

230

270

366

380

515

81

110

128

174

7/8 - 9

165

224

430

583

600

813

125

169

194

263

1 - 8

250

339

645

874

900

1220

184

249

287

389

1 1/4 - 7

500

678

1120

1518

1500

2034

336

456

523

709

.

e..Tighten.belts.to.proper.belt.tension..Record.the.

belt.tension.used..See.drive.mounting.section.for.

tensioning.instructions..Proper.tension.is.specified.

in.the.datasheet.included.with.the.fan.

11..Fans.that.have.motors.and.drives.mounted.at.the.

factory. are. trim. balanced. prior. to. shipment.. This.

is. not. possible. on. units. that. are. shipped. without.

motors. and. drives.. The. addition. of. drive. compo-

nents.in.the.field.can.create.unbalance.forces..Twin.

City. Companies,. Ltd.. recommends. final. balancing.

of.the.unit.after.the.drive.components.are.installed..

Failure.to.do.so.voids.the.Twin.City.Fan.Companies,.

Ltd..warranty.

12..Repeat.the.installation.checks.indicated.for.factory.

assembled. units. to. assure. proper. tightness. and.

alignment.of.all.components.

Bearing Installation

Bearings.are.only.to.be.field.installed.when.accompa-

nied.by.installation.instructions.from.the.bearing.manu-

facturer.. When. field. installation. is. required,. follow. the.

manufactures.instructions.carefully.to.install.bearings.

Table 1. Bolt Tightening Torque

METRIC SHAFTS

SET SCREW SIZE

LOCKING COLAR SCREW SIZE

Manufacturer

BRG ID

Units

M5

M6

M8

M10

M12

M4

M5

M6

M8

Dodge

S2000

N-m

-

-

17.8

35

57

-

-

-

-

Dodge

SCAH

N-m

3.4

6.9

16

28

51

5.85

10.75

20.5

45

Dodge

SCMAH

N-m

3.4

6.9

16

28

51

5.85

10.75

20.5

45

SKF

SY

N-m

See.Below

4.2

7.4

Table 2b. Metric Set Screw Torque Specifications

SY BEARING DIAMETER

PB224 BEARING DIAMETER

Manufacturer

BRG ID

Units

12-35mm 40-45mm 50-65mm

70-100mm

25,30mm 35-50mm

55mm

60-80mm 90,100mm

SKF

SY

N-m

4.

6.5

16.5

28.5

-

-

-

-

-

Linkbelt

PB224

N-m

-

-

-

-

21

37

52

77

153

Table 2a. Bearing Cap Bolt Torque Specifications (see page 6)

Bolt

Size

Bushing

Type

Iron/Steel Hub,

Sheave

Aluminum

Hub

Ft - lbs

N - m

Ft - lbs

N - m

1/4 - 20

H

8

11

8

11

5/16 - 18

P,.B

17

23

13

18

3/8 - 16

Q,.R

30

41

24

33

1/2 - 13

S

70

95

-

-

Table 3. Browning Split Taper Bushing Tightening Torque

Table 2c. IP Set Screw Torque Specifications (see page 7)

Set Screw

Size

Steel Set Screws

Stainless Set Screws

Ft - lbs

N - m

Ft - lbs

N - m

1/4 - 20

5.5

7.5

5.8

7.9

5/16 - 18

11

15

11

15

3/8 - 16

22

30

19

26

7/16 - 14

30

41

28

38

1/2 - 13

55

75

42

57

5/8 - 11

100

136

82

111

3/4 - 10

170

230

115

156

7/8 - 9

165

224

-

-

1 - 8

250

339

-

-

1 1/4 - 7

500

678

-

-

Table 4. Set Screw Tightening Torque (other than bearing

set screws)

Figure 5.

Sheave Alignment