Twin City TSL & QSL; Inline Centrifugal and Mixed Flow Fans - ES-895 User Manual

Tsl and qsl inline centrifugal and mixed flow fans, Es-895

Introduction

This bulletin has been prepared to guide the users of

TSL Inline Centrifugal Fans and QSL Mixed Flow Fans

in the proper installation, operation and maintenance

procedures to insure maximum equipment life with

trouble-free operation.

Shipping and Receiving

All Twin City Fan & Blower products are carefully con-

structed and inspected before shipment to insure the

highest standards of quality and performance. Compare

all components with the bill of lading or packing list to

verify that the proper unit was received. Check each unit

for any damage that may have occurred in transit. Any

damage should be reported immediately to the carrier

and the necessary damage report filed.

Handling

Handling of all air moving equipment should be con-

ducted by trained personnel and be consistent with safe

handling practices. Verify the lift capacity and operating

condition of handling equipment. Maintain handling

equipment to avoid serious personal injury.

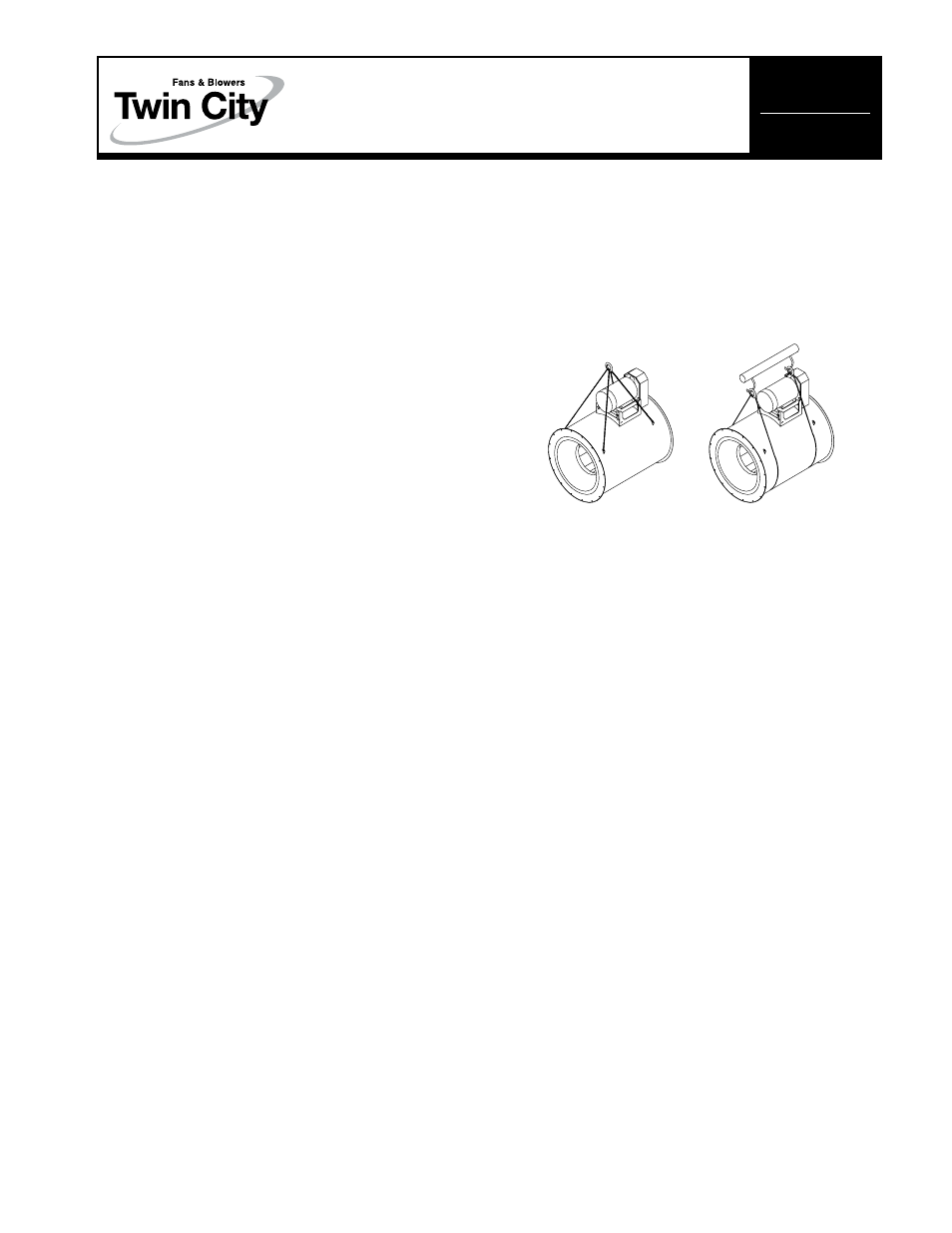

Units shipped completely assembled may be lifted

with slings and spreader bars. Use well-padded chains,

cables or nylon straps (see Figure 1). On most units,

lifting lugs are fashioned to protect the fan and fan

housing from damage. Never lift a fan by the inlet or

discharge flange, shafting or drives, wheel, motor or

motor base, or in any other manner that may bend or

distort parts.

If installation is to be delayed, store the unit in a

protected area. Protect the fan and motor bearings from

moisture and vibration (or shock loading). For extended

storage, wrap entire unit in plastic. Wrap loosely so air

may circulate around the fan and moisture does not

collect, or use a desiccant. Extended storage requires

monthly inspections. Check for corrosion or damage to

the unit and for debris within the fan. Rotate the fan

wheel a few revolutions. Stop the wheel in a position

other than the initial position. Grease the bearings every

month with a grease compatible with the grease sup-

plied with the bearings.

Foundations and Supporting Structures

The TSL and QSL series can be mounted horizontally,

vertically, or at any angle if ordered accordingly. Mounting

brackets are available to accept both vibration isolating

hangers or pads. Typical mounting arrangements are

shown in Figures 2 through 8. Floor or wall mounted

fans may be installed on a flat, rigid foundation.

When mounting to concrete, anchor bolts should be

“L” or “T” shaped with sufficient length for nuts, wash-

ers, shims, and threads for draw-down. Each bolt should

be placed in a sleeve or pipe with diameter larger than

the bolt to allow for adjustment. When the mounting

surface and the surface of the fan base do not match,

shim level. Do not distort the fan when tightening the

anchor bolts.

A fan mounted to or within a structure should be

placed as close as possible to a rigid member such as

a wall or a column. The structure must be designed for

rotating equipment. Static design for strength is not suf-

ficient to insure operation at low vibration levels. Supports

for suspended fans must be cross-braced to prevent

side-sway. Structural resonance should be at least 20%

from fan operating speed. Vibration isolators may help

block the transmission of vibration into a structure.

Any ducting should have independent support; do not

use the fan to support ducting. Flexible connections are

required whenever the fan is supported on vibration iso-

lators.

Fan Installation, Factory Assembled Units

Follow proper handling instructions as given earlier.

1. Move the fan to the final mounting position.

2. Remove skid, crates and packing materials carefully.

3. Attach vibration isolators (if used) to appropriate

mounting clips on fan. Locate fan in position using

lifting instructions above.

4. Carefully level unit using shims (on rigid mounted

fans) at mounting hole locations. Fans mounted with

vibration isolators may be leveled by adjusting the

hardware.

5. Continue with Operations Checklist.

Motor Maintenance

The three basic rules of motor maintenance are:

1. Keep the motor clean.

2. Keep the motor dry.

3. Keep the motor properly lubricated.

Blow dust off periodically (with low pressure air) to

prevent motor from overheating.

Some smaller motors are lubricated for life. Lubrication

requirements are normally attached to the motor. Use

the motor manufacturer’s recommendations for relubrica-

tion. If this information is not available, the following

schedule may be used. Motors less than 10 HP running

about eight hours a day in a clean environment should

be lubricated once every five years; motors 15 to 40

HP, every three years. For motors in dusty or dirty

environments or running 24 hours a day: divide the

service interval by 4. Do not over lubricate.

Drive Maintenance and Installation

V-belt drives need periodic inspection, retensioning, and

occasional belt replacement. When inspecting drives,

look for dirt buildup, burrs or obstructions that can

Figure 1.

Lifting With Lifting Lugs

Lifting With Straps &

(Standard)

Spreader Bar (Not Provided)

©2014 Twin City Fan Companies, Ltd.

ES-895

August 2014

TSL and QSL Inline Centrifugal

and Mixed Flow Fans

INSTALLATION, OPERATION & MAINTENANCE MANUAL