Twin City Air Kit Fans - ES-56 User Manual

Air kit fans, Es-56, Kit concept

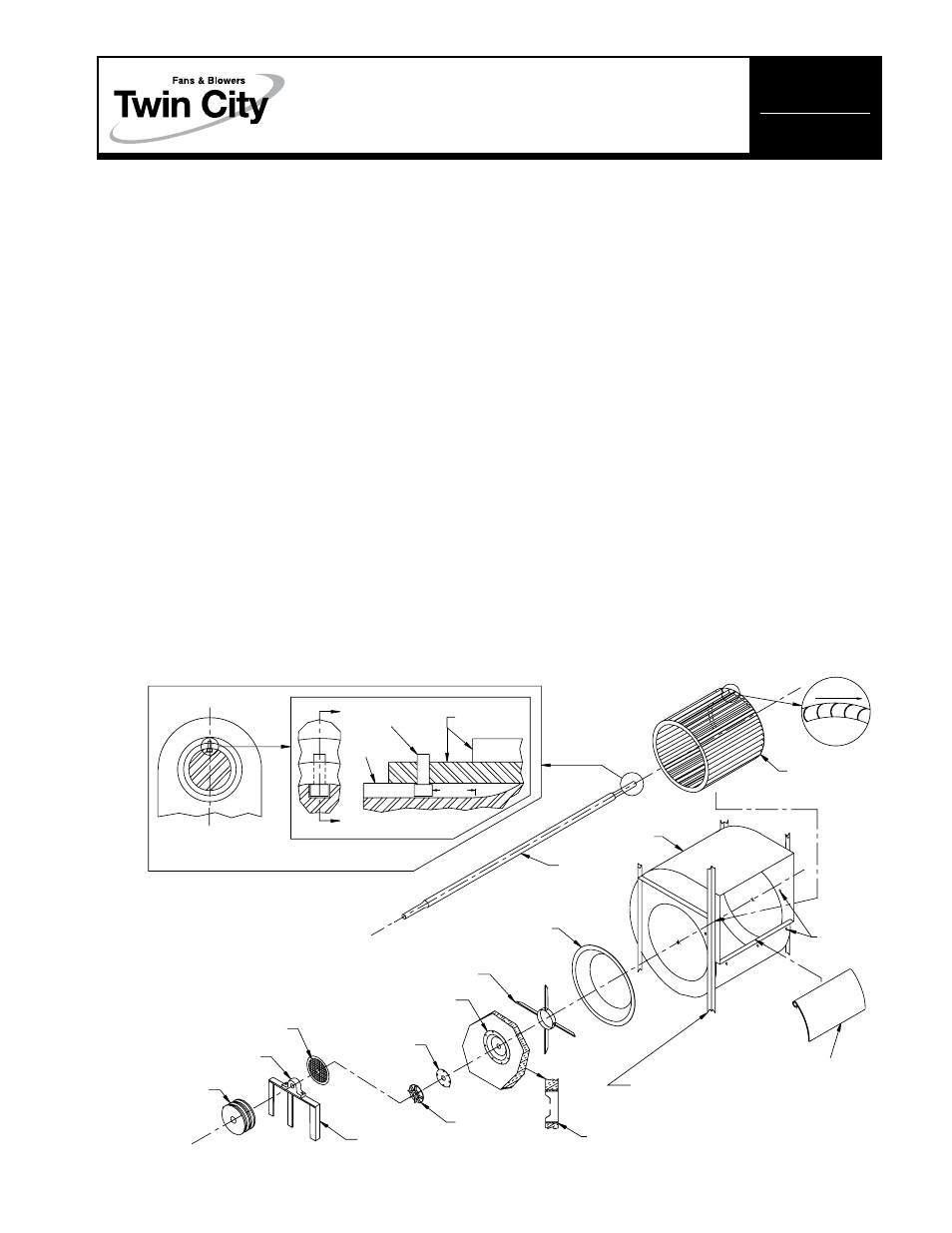

Kit Concept

Air kits (or fan kits) are sold as sets of components such

as wheels, housings, shafts, bearings, shaft coolers,

cooler guards, recess cones, straightening vanes and

shaft seals. Kits are installed and assembled by the

purchaser in a plenum or oven. The wheel (or wheels)

are supported on a shaft between two bearings.

The term “twin” is used to designate two wheels on

a common shaft. Spacing of the housings and wheels

in the plenum is done so that the inlet restriction is the

same on all inlets. More information about performance

and configuration specifics may be found in Bulletin 150.

Support Structure

Air kits are normally installed as part of another struc-

ture. These structures must be designed to withstand

both static and dynamic loading. The structural design

should follow the same guidelines for foundations and

supporting structures as found in ES-52. Proper design

of supports and supporting structures are the responsi-

bility of the purchaser.

Housing stiffeners or frame should provide rigidity and

support to the housing. Adequate rigidity can be pro-

vided by positioning bracing as shown in Figure 1.

Additional support may also be required. Supports

should not block the inlet or discharge of the fan. For

oven type applications the supports must be designed

so that the housing inlets will be centered with the

wheel when hot. Connecting ductwork should have inde-

pendent supports and have expansion joints or other

allowance for thermal expansion.

Bearing supports should be rigid enough to support

static and dynamic loads caused by belt pull and vibra-

tion. The bearing mounting surface should be flat and

square with the shaft axis centerline so that the bearings

are not subjected to loads from mounting misalignment.

The supports should be free from thermal effects which

can cause misalignment of bearings and designed so

that the bearing is not heated by conduction through

the pedestal or convection through the airstream. When

recess cones are combined with shafts having turn-

downs, the bearing supports should be removable to

allow for installation of the recess cone.

Air Kit Assembly and Installation

Components are assembled in order shown in Figure 1.

Since requirements vary, the purchaser assumes re-

sponsibility for the proper installation and operation of

the unit.

Assembly Preparation

Housings are mounted so that the inlets are equally

constricted. For twin fans, this means one-quarter of the

total clearance is at the outer fan inlets and one-half of

the total clearance is in the middle. Bearing pedestals

Note 5

Bearing

Components

Socket Head

Capscrew

Shaft

A

A

Section A-A

Opposite Side

Air Kit Housing

For Forward

Curved DWDI Unit

Shaft

Inlet Funnel

Air Kit Straightening Vanes

Air Kit Recess Cone

Shaft Seal

Shaft Cooler Guard

Drive Bearing (Fixed)

Opposite Bearing Expansion

Type (See Insert)

Drive Sheave

Bearing Pedestal

(Supplied By Others)

Shaft Cooler

Typical Oven Type Installation.

Spacer Ring and Insulated

Wall Supplied By Others.

Support (or Stiffener or Frame)

Angles Required For Proper

Support of Housing. Supplied By

Others.

Removable Cut-off.

Drill Holes At Base

of Cut-off to Match

Holes in Scroll and

Mount With Bolts.

Cut-off

Mounting

Holes

Air Kit Forward Curve

Centrifugal Type Wheel

Rotation

Shaft Expansion Modification (Typical)

Figure 1. General Assembly of Twin City Fan & Blower Air Kit

Notes:

1. Air kit components available separately or in almost

any combination.

2. Inlet funnel is formed as part of housing side on

some sizes.

3. Bearing pedestal must be designed to support

dynamic loads (supplied by others).

4. A variety of materials are available for many compo-

nents for special application. Consult factory for

details.

5. One inch for thermal expansion typical.

ES-56

June 1998

Air Kit Fans

INSTALLATION, OPERATION & MAINTENANCE MANUAL