Top Flite Antares User Manual

Page 9

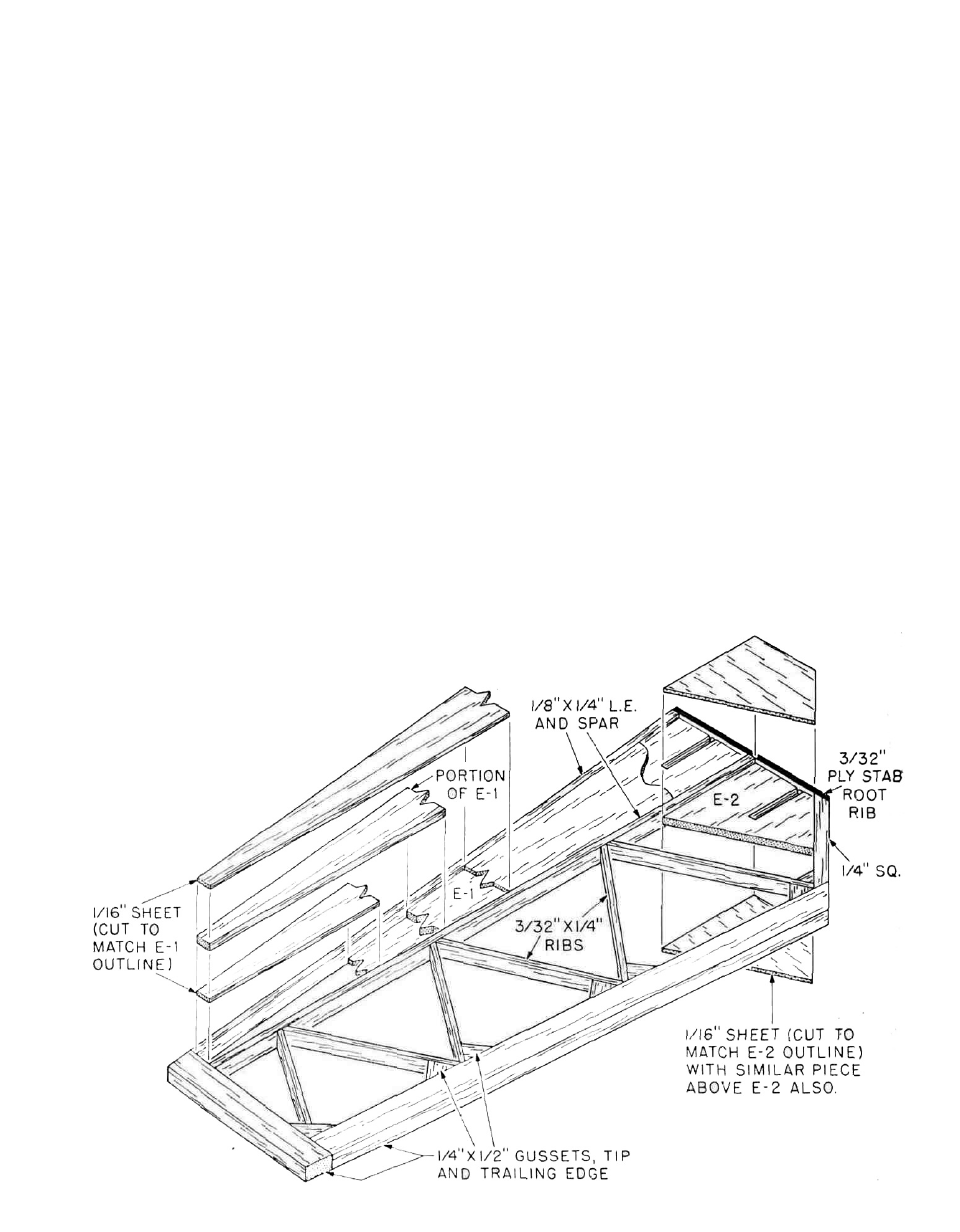

kind, since the right angles are important. At this

point, if you are going ahead with the VA" stabs, you

should trim Vis" off of each side of these ribs. We

would suggest that now is a good time to check and

make sure that these holes are properly spaced and

will fit. Locate four (4) Va" O.D. x TVie" brass tubes and

the two W dia. x 2%" M.W. stab joining wires. Tem-

porarily install the four tubes into the holes in the ply

stab root ribs and assemble these to the fin with the

joining wires. The fit should be smooth and non-

binding when moved up and down at the front of the

fin. All of this serves to confirm that the hole spacing

is correct—if it isn't, correct as needed.

3. Next, take one of the 1/8" O.D. stab tubes and slip the

1/8" I.D. wheel collar over one end. As shown on the

plans, mark the location of the wheel collar's set-

screw hole, r e m o v e t h e c o l l a r a n d f i l e o r g r i n d a notch

into and through the wall of the tube large enough to

let the set-screw pass, when tightened. Carefully

clean-out any metal "flash" on the inside and outside

of the tube, re-install the collar and test fit the set-

screw for clearance. Once satisfied, apply a small

amount of thick CA adhesive to the collar tube joint.

This is your one and only stab-locking tube (see stab

plan).

4. Cut or route-out a slot in one of the rear E-2's to accept

the wheel c o l l a r — t r i a l - f i t to be sure. Leaving the tube

and collar in place in the E-2 part, fit and hold two of

the 1/16" balsa laminates in place with your fingers,

press firmly with your fingers to create the collar's

indention on the inside of each skin. "Scoop-out"

balsa carefully from the indented areas, thus leaving

clearance for the collar. In the bottom skin, carefully

make a 1/8" hole for the set-screw.

5. Assemble the stabs directly over the plans starting

with accurately locating and pinning in place the 1/8"X

1/4" upright "spar". Assemble the rest of the stab

structure as shown being careful to not get glue into

the joiner tubes. Be sure to use epoxy to secure the

tubes into their respective slots and that these tubes

are laying flat.

6. When dry, remove the stabs from the plan and use

your sanding block to sand them flat. Next, hold them

together and "match" their outside shapes—you

want them identical. Before going any further, trial-fit

the stabs to the fin. You will have to trim a little of the

length of the joiner wires to get the stabs to fit flush

with the fin sides as we have left these a little longer

for fitting purposes. What you're looking for during

this trial-fit is that the two stabs sit at 90° to the fin

sides and that their roots are flush with the fin sides

as well. Remove the stab halves and the joiner wires.

File or grind a small "flat" on one end of the rear

joiner wire for the set screw to bottom-out on when in

place—re-install and test-fit, including the set-screw.

Once satisfied, remove all of the components from

the fuselage.

7. As with the rudder, use your sanding block and 120

grit sandpaper to carefully bring the stabs down to

the cross sections shown. Note that what you are

trying to achieve here is a symmetrical airfoil. Also

9