Top Flite Antares User Manual

Page 12

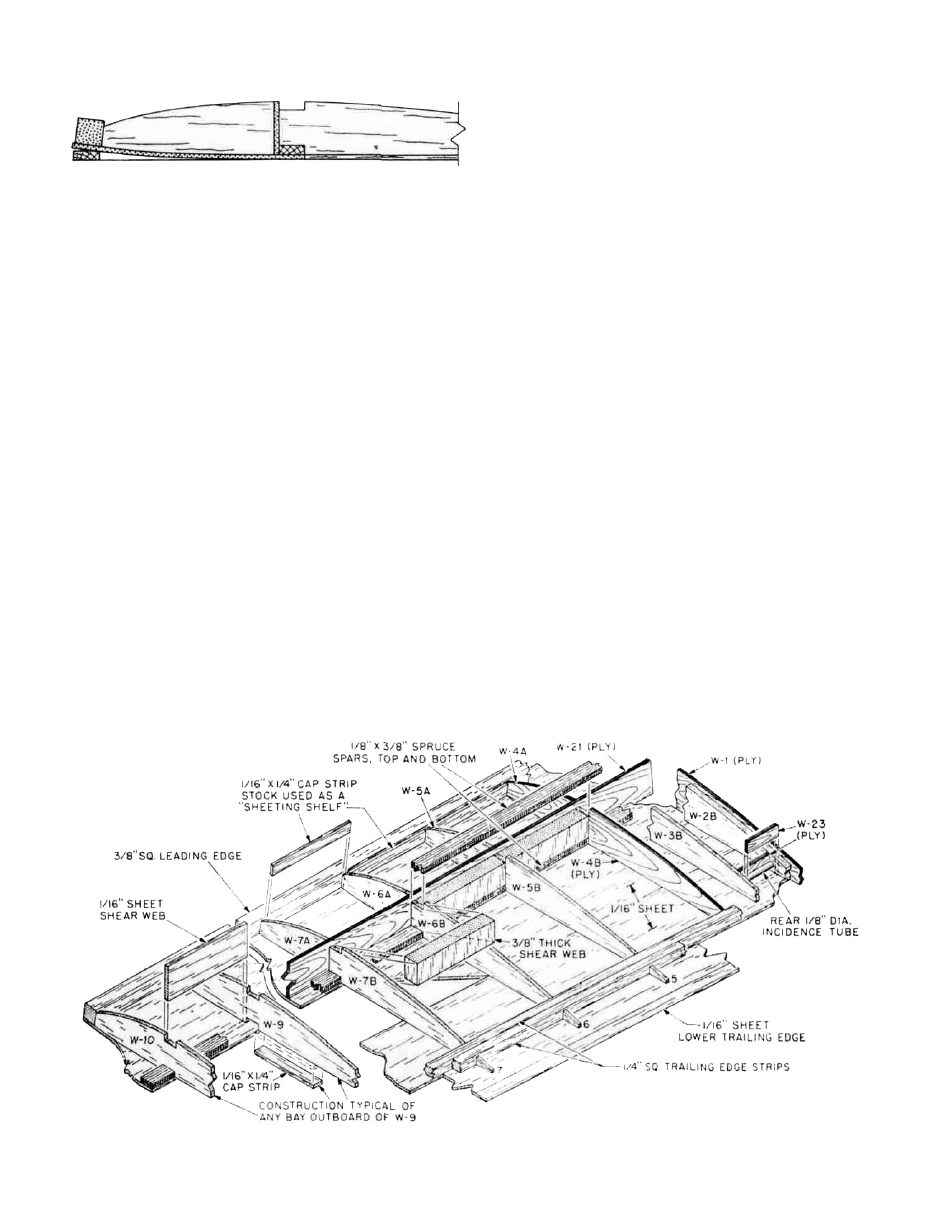

NOTE HOW UPPER SPAR IS USED AS A WEDGE

TO SUPPORT BOTTOM FRONT SHEETING

WITH WING F R A M E W O R K PINNED TO A FLAT

WORK AREA, PRESS SPAR BACK UNTIL THE

SHEETING MATCHES RIB CONTOUR

mate center of the 1/4"dia pencil mark you just made

on W-2A Using this rib as your guide, drill similar 1/8"

dia holes through all of the remaining ribs that hold

the aileron cable tube—W 3A through W 15

9. Starting with tip rib W 20 and working inboard, glue

all wing ribs in place * Use a triangle or a small block

with right angles to ensure that these ribs are in place

at 90° to the bottom sheeting *NOTE W-2A is

installed at the same angle as the inboard end of

W-21, this provides the root dihedral angle required.

Do not install W-2B or W-3B at this time.

10. Locate and glue the 3/8" sq leading edge in place

11 Cut, glue and fit the 1/16" x 1/4" "sheeting shelves" that

fit between each rib, flush with their top edges and

against the inside of the 3/8 sq leading edge These

are made from the 1/16" x 1/4" x 36 stock provided

12. Locate, remove and glue in place all of the aileron and

flap "riblets" on the bottom sheeting, againstthe rear

edge of the 1/4"sq stock in place Note that there are

two #12's provided for each wing panel and that they

are glued in place on each side of the aileron flap cut

made earlier, use a piece of card stock to space them

13. Remove the top spars from underneath the leading

edges of the wing panels and temporarily install

them into the top rib slots Align their inboard ends

flush with the top inboard end of W-21 Using the

spars as spacers, glue the rear ply W 22's in place to

the bottom sheeting and the rear face of the bottom

spar—do not glue to the top spdr Note that W 22 is

meant to fit from the inboard edge of the bottom

wing sheeting out to rib W 4B Remove the top spar

and re-install it beneath the leading edge of the wing

panel

14 Locate the bag containing the 3/8" x 5/8" x 3" vertical-

grain balsa shear webs These are now trimmed and

accurately installed between each rib starting from

W 4B out to W 20 Note that these webs must be

carefully fitted in place between each r i b and the top

and bottom spar locations—do not allow any gaps or

bad joints, the integrity of your wing depends on

these webs!

15 Use the 1/16" x 1 " x 36 balsa strips provided to cut, fit

and glue in place the horizontal grain web facing

caps which are full depth, from W 9 through W 20

These are glued to the front faces of all the 3/8" vertical

webs just installed—see plans and cross sections

16 In this step we want to prepare the top of the wing for

sheeting This is best done with the largest, longest

Sanding bloc k that you have with light sandpaper

The tops of the 1 / 4 " sq trailing edges and the 1/4" sq.

aileron and flap leading edges have to be tapered as

shown on the plans Also, the bottom, trailing edge

sheeting must be tapered as shown Take your time

here to ensure accuracy We have used masking tape

over the ribs, in front of and behind the 1/4" sq.

material to avoid gouging Once satisfied, cut, fit and

glue the 3/32" ply aileron and flap horn mounts into the

locations shown (riblet 8 and 16) These too are

tapered—see cross sections

17 Locate and mark the required hole positions for the

aileron and flap horns (4 40 flat head bolts) The

measurement from the hinge line back to the center-

line of these holes is 5/16" Drill these holes, at right

angles to the work surface with either a 5/64" dia drill

bit or a #42 index bit

12