Top Flite TOPA0712 User Manual

Page 15

15

❏

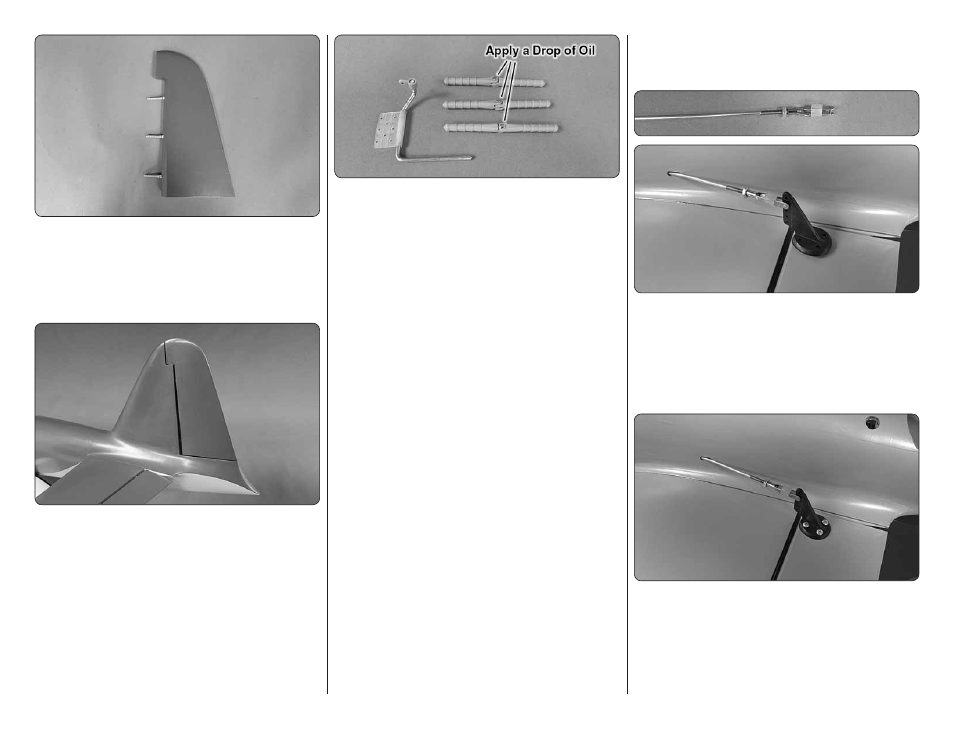

6. Without using any glue, install three hinges into

the holes in the trailing edge of the rudder. Note that the

pivot point of each hinge must align with the center of

the trailing edge. To achieve this alignment, the hinges

will be fairly deep in the fi n. Also note that the hinges

must be perpendicular to the leading edge.

❏

7. Again without glue, test fi t the rudder to the fi n

making sure the rudder control wire fi ts into the hole in

the bottom trailing edge of the rudder. With everything

assembled make sure the rudder moves freely and

the rudder control wire moves in the fuselage without

obstruction.

❏

8. Remove the rudder, control wire and all of the

hinges. Add a small drop of oil to the pivot point on the

hinges and to the control wire where it passes through

the nylon bearing. This will prevent the epoxy from

adhering to the pivot point and the wire. Make sure oil

does not get on the gluing surface of the hinge or the

nylon bearing. If it does, clean the oil off with a paper

towel square dampened with denatured alcohol.

❏

9. Mix up approximately 1/4 oz. [7.4cc] of 30-minute

epoxy. Use a toothpick to thoroughly apply the epoxy in

the holes in the fi n and rudder and the hole in the rudder

for the rudder control wire. Use the toothpick to get the

epoxy out of the opening of the holes in the rudder

and fi n so it doesn’t get into the hinge pin. Wipe away

any excess epoxy around the outside of the holes with

a couple of the small paper towel squares dampened

with denatured alcohol.

❏

10. Use a toothpick to apply epoxy to the ends of the

rudder hinges that go into the fi n. Insert each hinge into

the fi n and wipe away any excess epoxy that squeezes

out of the hole.

❏

11. Apply epoxy to the nylon bearing tongue on the

rudder control wire. Be careful not to get glue between

the nylon bearing and the wire.

❏

12. Apply epoxy to the other end of the hinges. Join

the rudder to the fi n, pushing the hinges only about

3/4 of the way into the rudder. Use a toothpick to wipe

away any epoxy that squeezes out. Be sure the nylon

bearing is inserted into the hinge slot in the vertical fi n

and the wire fi ts into the hole in the rudder. Then fi t the

rudder the rest of the way in.

❏

13. Move the rudder left and right to align the hinges.

If needed, use a length of masking tape to hold the

rudder to the fi n. Allow the glue to fully cure.

❏

14. Cut a 4-40 x 48" [1220mm] metal pushrod to a

length of 33" [838mm]. Install a 4-40 nut, silicone clevis

keeper and 4-40 threaded clevis on the threaded end of

the metal pushrod. Install the clevis into the hole second

from the bottom of a large black control horn. Insert the

pushrod wire into the pushrod hole in the right side of the

fuselage until the control horn is resting on the elevator.

❏

15. Where the elevator control horn rests on the

elevator there is a plywood plate. Position the horn

over the plate on the elevator. Drill a 3/32" [2.4mm] hole

through each of the holes in the control horn. Drill only

through the plywood plate. Do not drill through the top

of the control surface. Mount the horn with four #4 x

1/2" [13mm] screws.