Step 8 — make electrical connections – Carrier WEATHERMAKER 48AJ User Manual

Page 20

20

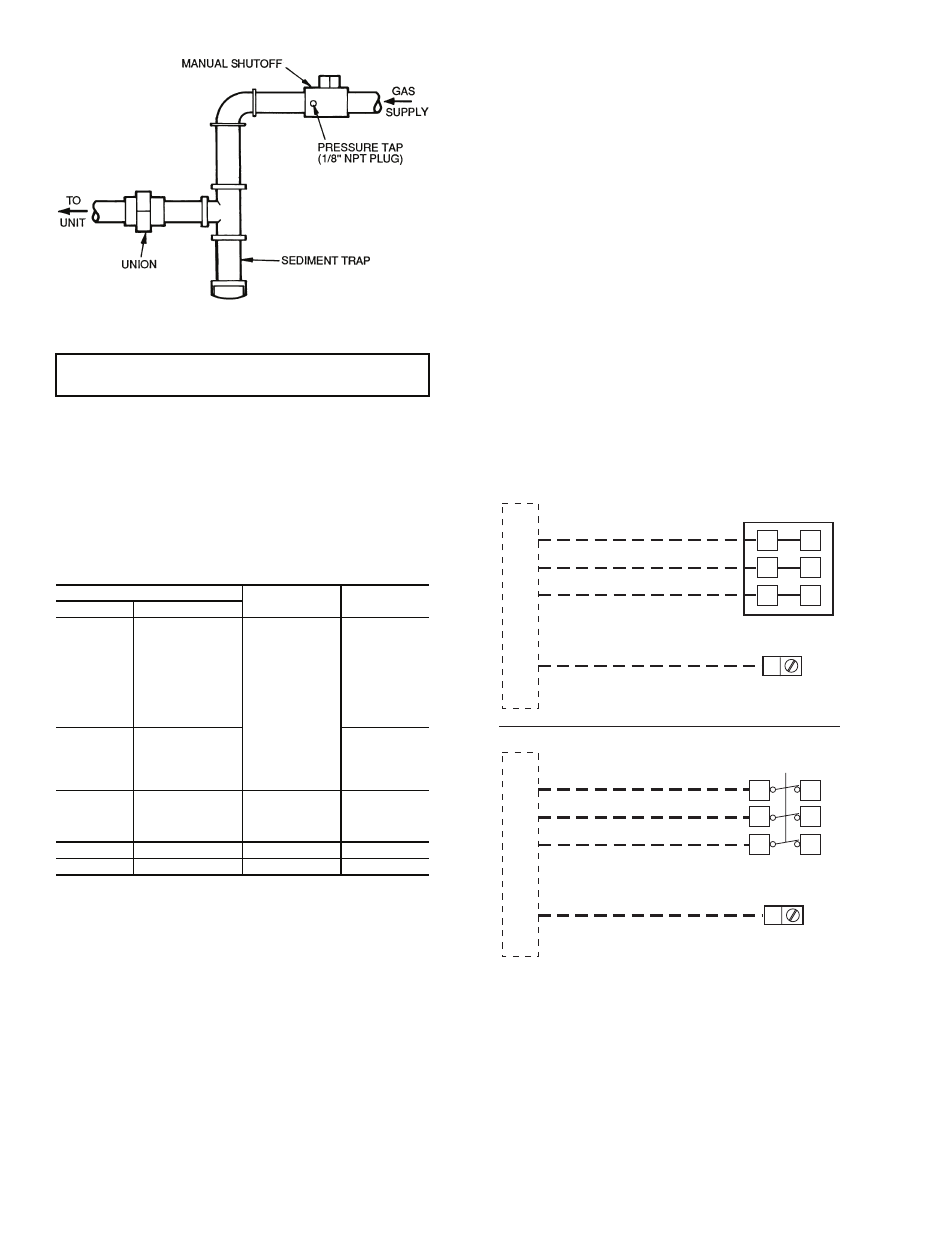

Size gas-supply piping for 0.5-in. wg maximum pressure

drop. Do not use supply pipe smaller than unit gas connection.

OPTIONAL STAGED GAS UNITS — See Table 7 for staged

gas information. Staging pattern is selected during controls

start-up.

For complete information and service instructions for

Staged Gas Control Units, see Control Operation and Trouble-

shooting literature.

Table 7 — 48A Series Staged Gas Control

Step 8 — Make Electrical Connections

POWER WIRING — Units are factory wired for the voltage

shown on the unit nameplate.

Provide a unit safety disconnect switch in the main power

supply to each unit (see Fig. 19). Select switch size and mount-

ing location in accordance with applicable local codes or

National Electrical Code (NEC). If combining the functions of

safety disconnect with maximum overcurrent protection

(MOCP) fuses (“fused disconnect”), coordinate safety switch

size with MOCP size data as marked on unit informative plate.

Unit may be equipped with optional factory-installed non-

fused disconnect switch (see Fig. 19). Provide maximum

overcurrent protection devices (fuses or HACR breakers, per

local codes) in branch circuit wiring remote from unit. Observe

requirements of NEC Article 440. Install service switch

upstream of remote fuses if required.

The main power terminal block is suitable for use with

aluminum or copper wire. See Fig. 19. Units have circuit

breakers for compressors, fan motors, and control circuit. The

unit must be electrically grounded in accordance with local

codes, or in absence of local codes, with NEC, ANSI C1-latest

year.

FIELD POWER SUPPLY — Unit is factory wired for volt-

age shown on unit nameplate. See Tables 8A and 8B for elec-

trical data.

Field wiring can be brought into the unit from bottom

(through basepan and roof curb) or through side of unit (corner

post next to control box).

A 3

1

/

2

-in. NPT coupling for field power wiring and a

3

/

4

-in.

NPT coupling for 24-v control wiring are provided in basepan.

In the side post, there are two 2

1

/

2

-in. (48A020-035) or 3-in.

(48A036-060) knockouts for the field power wiring. See

Fig. 4-9. If control wiring is to be brought in through the side of

unit, a

7

/

8

-in. diameter hole is provided in the condenser side

post next to the control box.

Do not route control wiring in the same conduit as power

wiring.

If disconnect box is mounted to corner post, be careful not

to drill or screw into the condenser coil.

IMPORTANT: Natural gas pressure at unit gas connection

must not be less than 5 in. wg or greater than 13.5 in. wg.

MODEL NUMBER POSITION

NUMBER OF

STAGES

HEAT SIZE

5

6,7,8

S

020

025

027

030

035

036

040

041

050

5 stages

Low

T

035

036

040

041

050

High

T

020

025

027

030

7 stages

High

T

051,060

9 stages

High

S

051,060

11 stages

Low

Fig. 18 — Field Gas Piping

a48-2524

FIELD SUPPLIED

DISCONNECT

PER NEC

FIELD

POWER

SUPPLY

11

21

22

23

13

12

TB1

EQUIP GND

FIELD POWER WIRING

11

21

22

23

13

12

GND

OPTIONAL

FACTORY-INSTALLED

DISCONNECT

FIELD-INSTALLED DISCONNECT

FACTORY-INSTALLED DISCONNECT

LEGEND

GND — Ground

NEC — National Electrical Code

TB

— Terminal Block

Fig. 19 — Field Power Wiring Connections

a48-6977