Charging the unit in ac mode, Charging charts & application notes, Figure 6. charging chart for 3 ton units – Reznor P8SE Unit Installation Manual User Manual

Page 12

12

• A low-pressure switch is factory-installed and located

in the suction line internal to the outdoor unit. The

switch is designed to protect the compressor from a

loss of charge. Under normal conditions, the switch is

closed. If the suction pressure falls below 5 psig, then

the switch will open and de-energize the outdoor unit.

The switch will close again once the suction pressure

increases above 20 psig. Please note that the switch

interrupts the thermostat inputs to the unit. When the

switch opens and then closes, there will be a 5 minute

short cycling delay before the outdoor unit will energize.

• To achieve rated capacity and efficiency the compressor

must be exposed to refrigerant for at least 24 hours prior

to running and then must be run for a minimum of 12

hours.

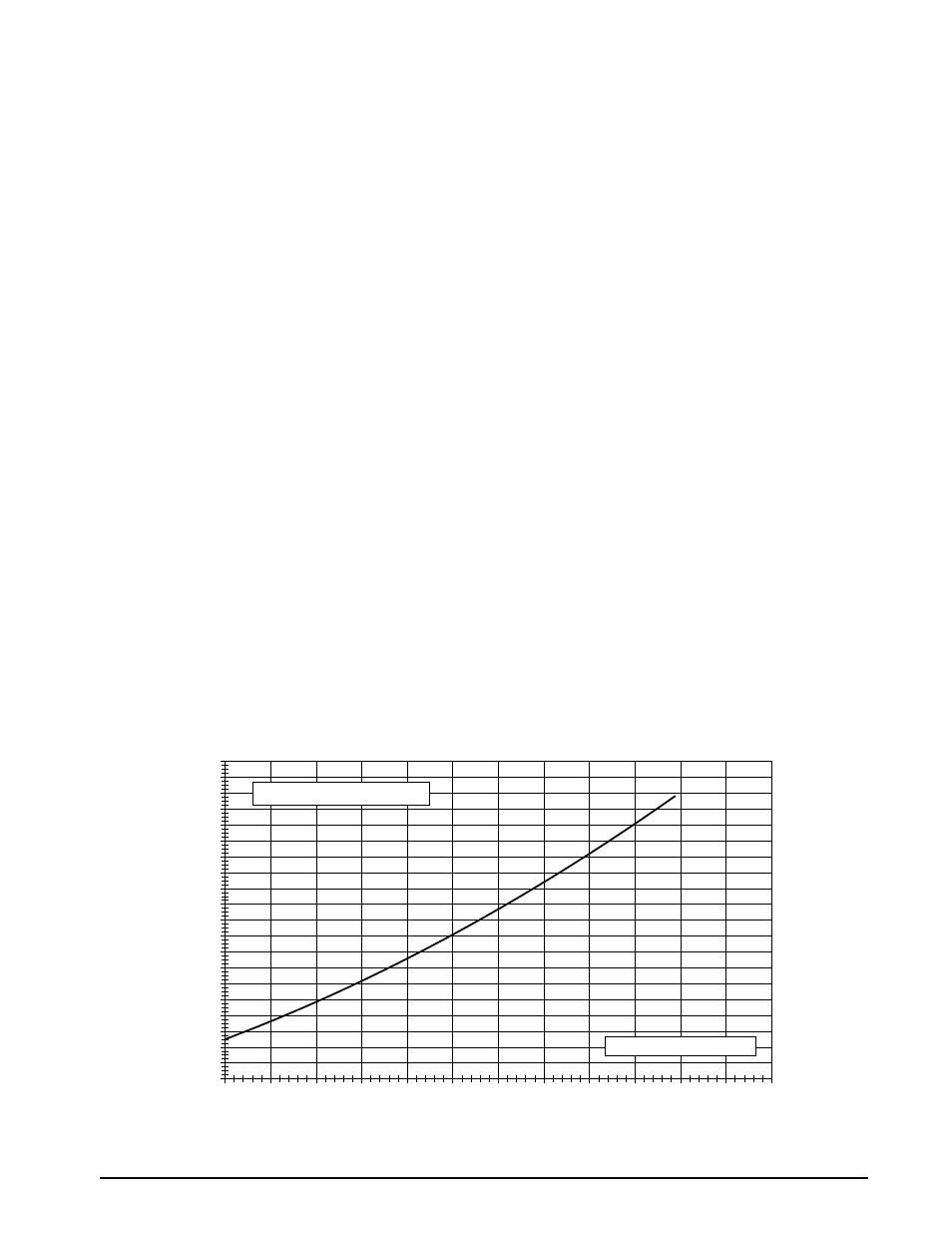

charging the unit in ac mode

At outdoor temperatures above 65° F

1. With the system operating at steady-state, measure

the liquid refrigerant pressure (in psig) at the outdoor

unit service valve.

2. Measure the liquid refrigerant temperature (in

Fahrenheit) at the service valve.

3. Determine the required liquid refrigerant pressure

from

,

.

• If the pressure measured in Step 1 is greater than

the required liquid refrigerant pressure determined

in Step 3, then there is too much charge in the

system. Remove refrigerant and repeat Steps 1

through 3 until the system is correctly charged.

• If the pressure measured in Step 1 is less than the

required liquid refrigerant pressure determined in

Step 3, there is too little charge in the system. Add

refrigerant and repeat Steps 1 through 3 until the

system is correctly charged.

charging charts & application notes

• This equipment’s cooling system contains refrigerant

under high pressure. Always use safe and environmen-

tally sound methods when handling refrigerant handling

or servicing the unit. Review the factory literature and

safety warnings prior to servicing.

• When repairing system leaks, always use a nitrogen

(inert) gas to protect the refrigerant system and pressure

check the repair before re-charging. Always replace

the filter-dryers when performing any repair to the

refrigeration system with one capable of acid removal.

After completing the repairs, evacuate the system to

350 - 500 microns and weigh in the refrigerant to the

amount specified on the unit rating label.

• The refrigerant charging charts,

,

, or

are applicable only to matched assemblies

of NORDYNE equipment and listed airflows for the

indoor coil. NOTE: Before using these charts, make

sure the unit is in a stable operating mode. As shown

in the charts, the ideal system sub-cooling can vary

over the range of operation. Reference the charts to

determine the ideal amount of sub-cooling for a given

liquid pressure. Units charged to other values will not

perform at the rated unit efficiency (EER).

• For systems that are operating with more than a 5%

deviation, inspect the unit for the proper voltage and

phase balance and the refrigeration system for leaks.

• Units that are operating at less then 95% of the nominal

voltage or with a 2% phase imbalance may see a more

significant deviation than the amount stated above.

• DO NOT use the charts in systems that have a fan cycling

under low-ambient control. Refer to the low-ambient kit

instructions for more information (If applicable).

75

80

85

90

95

100

105

110

115

120

125

130

Liquid Pressure (psig

)

Liquid Temperature (° F)

P8SE-X36 Charging Chart - Cooling

200

220

240

260

280

300

320

340

360

380

400

420

440

460

480

500

520

540

560

580

600

135

Remove refrigerant if above curve

Add refrigerant if below curve

Figure 6. charging chart for 3 ton units