Line voltage, Thermostat / low voltage connections, 2 stage heat/cool thermostat configuration – Reznor PDF2SF Unit Installation Manual User Manual

Page 11

11

√

Verify factory wiring is in accordance with the unit

wiring diagram (Figures 13 - 16, pages 31 - 34). Verify

none of the connections loosened during shipping or

installation.

Line Voltage

• The line voltage to the unit should be supplied from a

dedicated branch circuit containing the correct fuse or

circuit breaker for the unit.

•

An electrical disconnect must be located within

sight of and readily accessible to the unit

. This

switch shall be capable of electrically de-energizing the

outdoor unit. See unit data label for proper incoming field

wiring. Any other wiring methods must be acceptable

to authority having jurisdiction.

• Use only copper wire for the line voltage power supply

to this unit (Table 3, page 12). Use proper code agency

listed conduit and a conduit connector for connecting

the supply wires to the unit. Use of rain tight conduit is

recommended.

• Provide power supply for the unit in accordance with

the unit wiring diagram and the unit rating plate.

• Overcurrent protection must be provided at the branch

circuit distribution panel and sized as shown on the unit

rating label and according to applicable local codes.

See the unit rating plate for maximum circuit ampacity

and maximum overcurrent protection limits.

• A wiring diagram is located on the inside cover of the

control access panel of the outdoor unit. The installer

should become familiar with the wiring diagram before

making any electrical connections to the outdoor unit.

See Figures 13 - 16.

• If any of the original wires supplied with the unit must

be replaced, they must be replaced with material of

the same gauge and temperature rating.

• Units are shipped from the factory wired for 240 volt

transformer operation. For 208V operation, remove the

lead from the transformer terminal marked 240V and

connect it to the terminal marked 208V.

• Connect the line-voltage leads to the terminals on the

contactor inside the control compartment.

Thermostat / Low Voltage Connections

• These Gas / Electric units are designed to operate

with a 24 VAC Class II control circuit. The control circuit

wiring must comply with the current provisions of the

NEC (ANSI/NFPA 70) and with applicable local codes

having jurisdiction. Thermostat connections should be

made in accordance with the instructions supplied with

the thermostat and the indoor equipment.

• These units use a special 2 speed compressor to

achieve a high level of efficiency in a compact frame.

A 2 stage heat / 2 stage cool thermostat with back-

up fossil fuel heat capability is required with the

Dual Fuel iHybrid™ heat pump packaged system.

This system is capable of providing two stages of

cooling, two stages of heating in heat pump mode and

an additional 2 stages of secondary gas heating. See

Figure 12 (page 30)

• The low voltage wires must be properly connected

to the units low voltage terminal block. Route 24V

control wires through the gas furnace side of the unit.

Recommended wire gauge and wire lengths for typical

thermostat connections are listed in Table 4 (page 12).

• The thermostat should be mounted about 5 feet

above the floor on an inside wall. DO NOT install the

thermostat on an outside wall or any other location

where its operation may be adversely affected by radiant

heat from fireplaces, sunlight, or lighting fixtures, and

convective heat from warm air registers or electrical

appliances. Refer to the thermostat manufacturer’s

instruction sheet for detailed mounting information.

2 Stage Heat/Cool Thermostat Configuration

For proper operation and highest efficiency, a 2

Stage Heat Pump thermostat with back-up fossil fuel

capabilities is required for this product.

A 2 stage heat

pump thermostat is required to control the special 2 speed

compressor in both Heating and Cooling modes of heat

pump operation. The 2 Stage Heat Pump thermostat will

also allow the unit to operate as a two stage gas heat

system while set in the Emergency Heat mode.

Connect the low voltage thermostat wires between

terminals R (24VAC), Y1 (1st Stage Cool), G (Fan), Y2

(2nd Stage Cool), W1 (1st Stage Heat), W2 (2nd Stage

Heat), C (24V Com.), E (Emer. Heat), O or O/B (Reversing

Valve), and L (Defrost board fault monitoring-Optional)

on both the thermostat sub-base and unit low voltage

terminal board. See Figures 13 - 16 and your heat pump

thermostat installation manual for proper connections.

NOTE: Thermostats with a single “O/B” terminal for

selection of reversing valve control must be configured

for the “O” terminal to energize the reversing valve coil in

the cooling mode of operation.

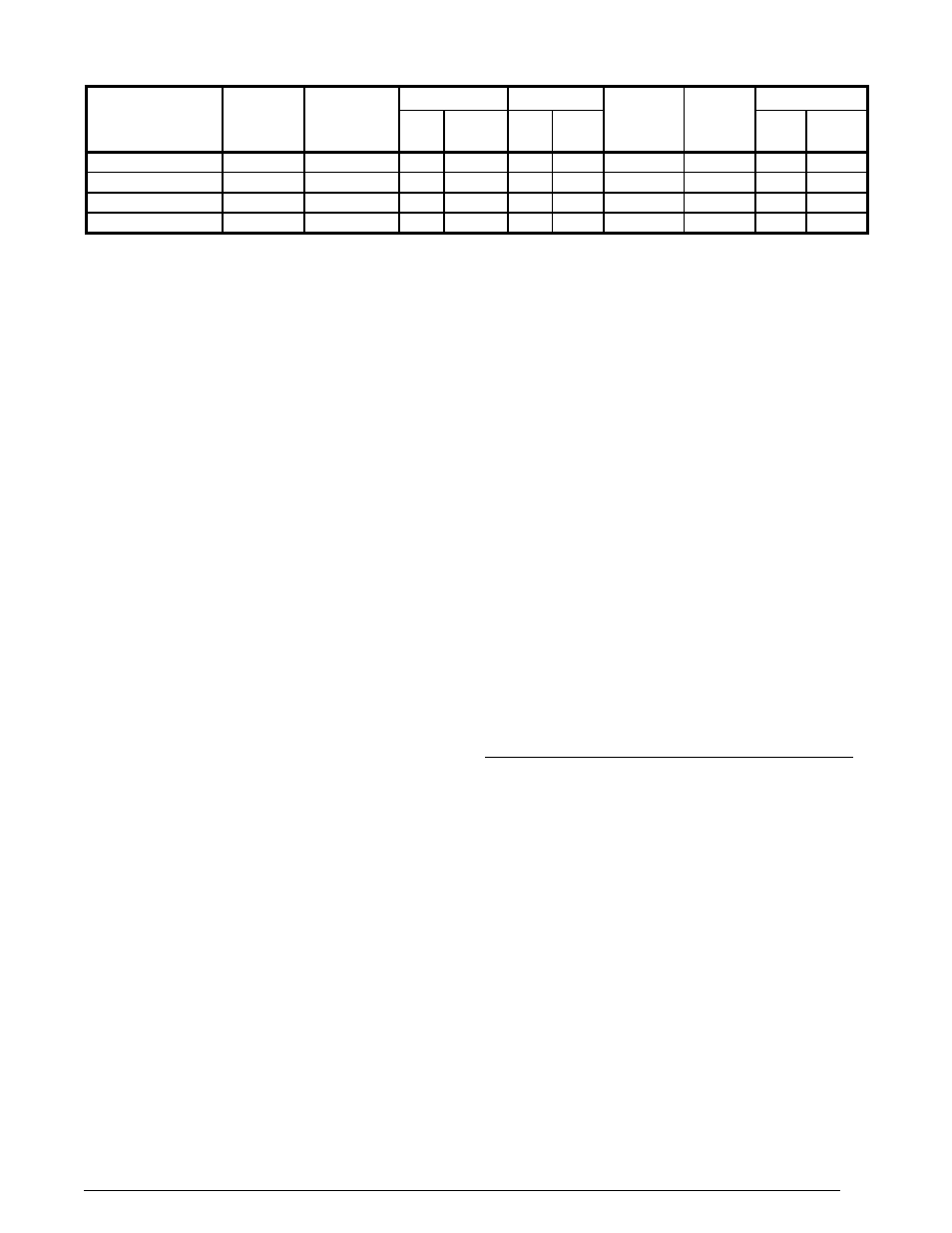

Table 2. Electrical Data

Model

Number

Maximum

Heating

Input

Nominal

Electrical

Supply

Voltage Range Compressor

Fan

Motor

FLA

Indoor

Blower

FLA

Single Circuit

Min

Max

RLA

LRA

MCA

MOP

X24K080CA

80,000

208-230/60/1

187

253

11.7

58.3

0.91

4.3

20.3

30.0

X36K100CA

100,000

208-230/60/1

187

253

15.3

83.0

2.6

6.8

29.0

40.0

X48K120CA

120,000

208-230/60/1

187

253

21.2

104.0

2.6

9.1

38.6

50.0

X60K120CA

120,000

208-230/60/1

187

253

28.8

152.9

1.46

9.1

47.0

70.0

Note:

FLA = Full Load Amps; LRA = Lock Rotor amps; RLA = Rated Load Amps.