Setting pan/tilt belt tension – PRG Best Boy Field Service Manual User Manual

Page 100

92

BEST BOY 4000

®

SPOT LUMINAIRE FIELD SERVICE MANUAL

Setting Pan/Tilt Belt Tension

Loose pan/tilt drive belts can create calibration problems. When the luminaire reaches the end of travel, excess belt

slack can produce a vibration causing the encoder to continue producing a movement output signal to the processor

(even though the luminaire is at its stop).

When properly set, the belt should not show bilateral deflection. Bilateral deflection may be observed by loosening the

tension adjustment bolt(s) and rotating the head assembly. As the head is rotated back and forth, tension is created

on one side and deflections are created on the other.

There are two ways to set proper belt tension:

1) Using a Sonic Tension Meter (recommended).

2) By manually tightening until no bilateral deflection is present.

When using the Sonic Tension Meter, it will be necessary to program separate presets for the Pan and Tilt Drive belts

as follows:

Tools & Supplies:

7/16" open-ended wrench,

or

Sonic Tension Meter, Model 507C (07.3082.1052.0)

CAUTION:

Do not overtighten belt, pulley will break and/or bearings will fail.

To set belt tension using a meter:

Step

1. Set Pan and Tilt presets on the Tension Meter as given above.

Step

2. Orient head as shown in Figure 3-60 on next page.

Step

3. Slowly tighten belt adjustment bolt(s). Use Tension Meter to verify correct tension.

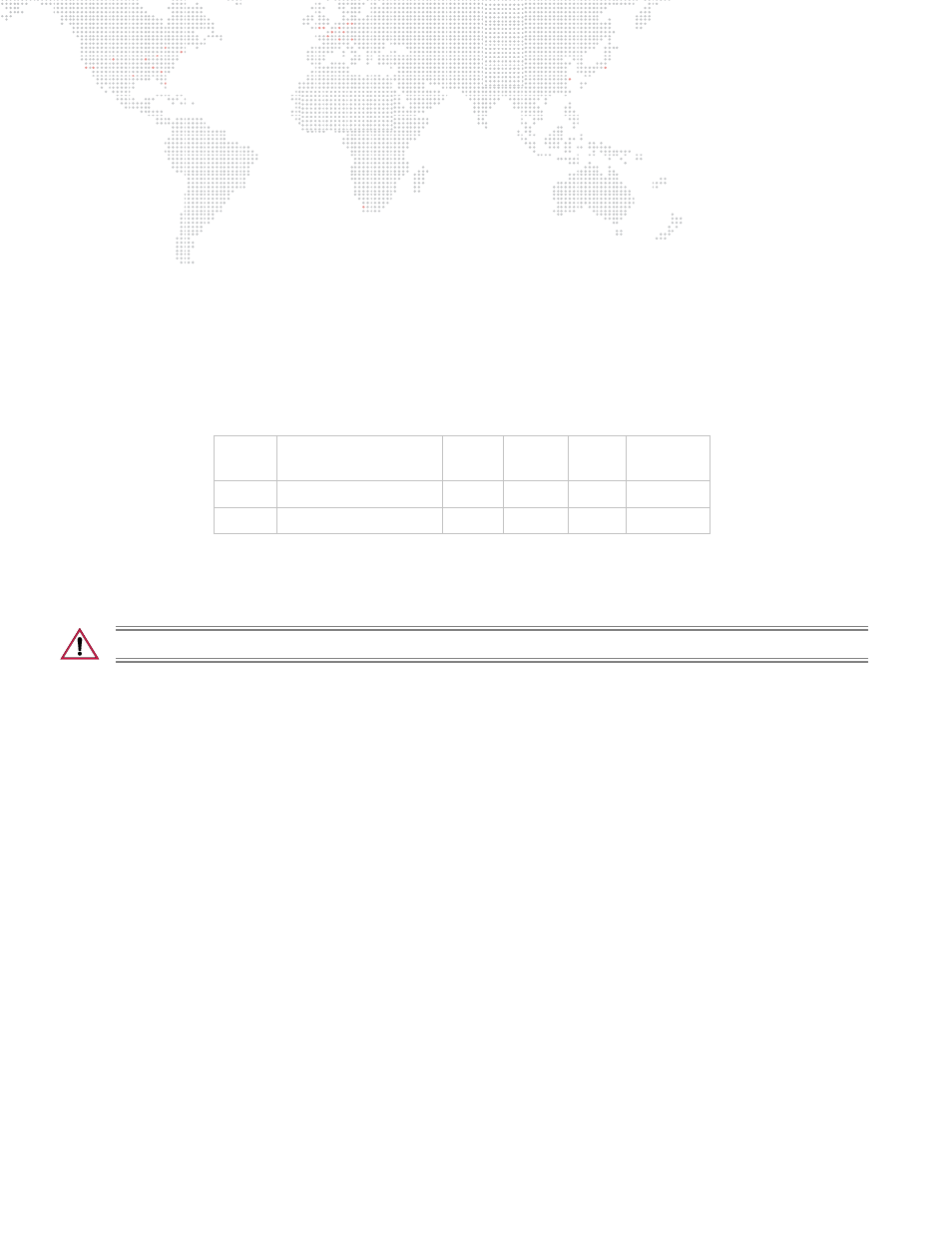

Preset

Belt

Mass

Width

(mm)

Span

(mm)

Tension

(lbs.)

14

Pan Final Drive

4.1

15

145

80-100

15

Tilt Final Drive

4.1

15

237

80-100