Feedback_effort, Loop_config – Maxim Integrated MAX15303 PMBus Command Set User Manual

Page 48

MAX15303 PMBus Command Set User’s Guide

Page 48 of 52

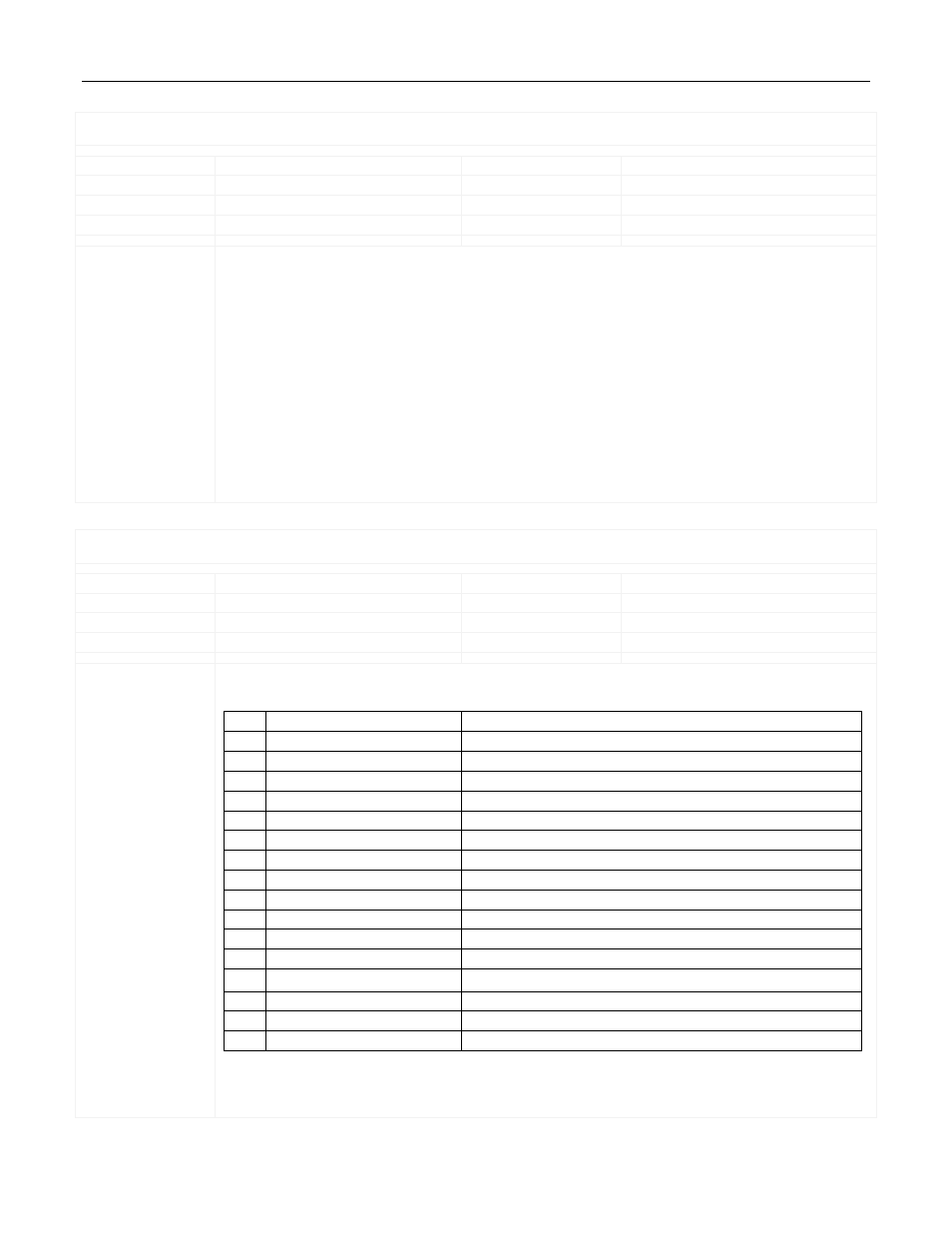

FEEDBACK_EFFORT

Reference:

Maxim Specific

Lockable:

Yes

Command Code:

0xD3

Format:

Linear

Data Bytes:

2

Units:

Scalar

Transfer:

Read Byte

Factory Value:

0xB200 (0.5)

Description/Notes: This command allows some user adjustment of the tradeoff between transient response, load

regulation, and output noise. The default value is 0.5, which provides a good balance of transient

response performance and output noise characteristics.

Lower values of FEEDBACK_EFFORT (as low as 0.0) will tend to provide lower output noise, at the

expense of transient performance and slightly reduced load regulation accuracy.

Higher values of FEEDBACK_EFFORT (up to 1.0) will provide improved transient response and load

regulation, at the expense of increased output noise and PWM waveform rising/falling edge “jitter.”

As a generalization, increasing FEEDBACK_EFFORT tends to increase effective control loop bandwidth,

while decreasing FEDBACK_EFFORT reduces bandwidth.

Wait at least 500μs for execution after sending the FEEDBACK_EFFORT command before sending

additional PMBus commands.

LOOP_CONFIG

Reference:

Maxim Specific

Lockable:

Yes

Command Code:

0xD5

Format:

Bit field

Data Bytes:

2

Units:

N/A

Transfer:

Read/Write Word

Factory Value:

0x0100

Description/Notes: The LOOP_CONFIG command configures miscellaneous control-loop features of the MAX15303. Each

bit in the two data bytes enables a particular function as follows:

Bit

Name

Effect When True

15

14

13

12

11

10

9

NOGAINCALC

The control loop will only use hard-coded NLSS gain values

8

PIDMODE

Enable integral term in the control loop (set by default)

7

6

5

4

AGDEN

Enable adaptive gate-drive timing system (not supported)

3

NEGDUTYEN

Enable low-side body diode “braking” on load-release transient

2

1

0

Wait at least 500μs for execution after sending the LOOP_CONFIG command before sending

additional PMBus commands.