Direct heating piping diagram, Modulating and sequencing boilers, System – LAARS M4-Ext - Installation Manual User Manual

Page 34: Laars heating systems, Rs-485 extension module, Ma gnd vlt, Ma temp outdoor o o temp system, Prove /dhw shutdown /setback

34

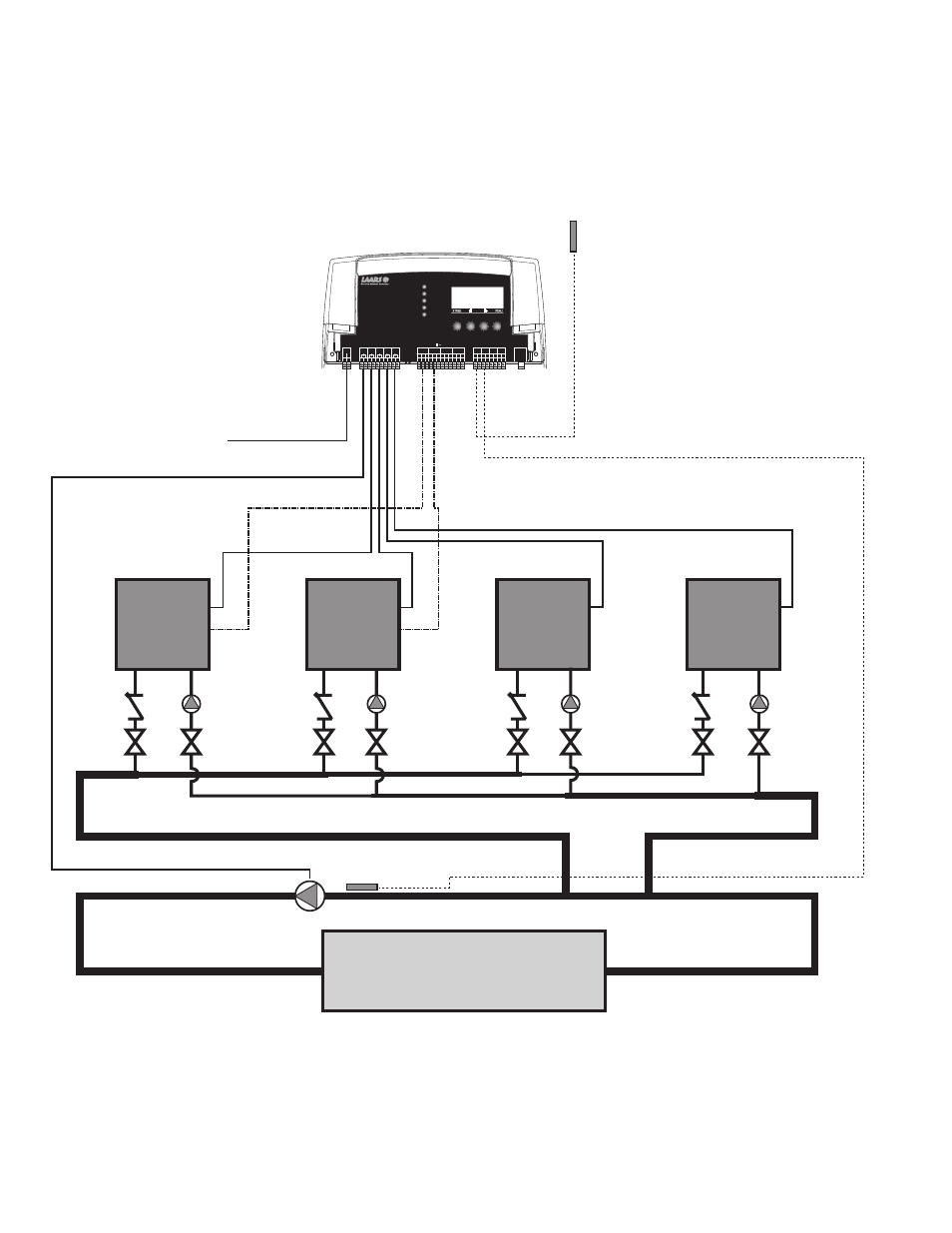

MOdULATiNg ANd SEqUENCiNg BOiLERS

diRECT HEATiNg PiPiNg diAgRAM

System:

The

M4-CNC operates 2 modulating boilers and 2 On/Off Boilers. The boilers are piped in Reverse Return on the primary

loop. The System output is controlling the System Pump.

Laars is aware that each installation is unique. Thus, Laars is not responsible for any installation related to any electrical

or plumbing diagram generated by Laars. The provided illustrations are to demonstrate Laars’s control operating concept

only.

LAARS Heating Systems

HT# 059104-00 B

Outdoor

Sensor

System

Sensor

120VAC

Boiler 1

Boiler 2

Boiler 3

Boiler 4

Building Heating Loop

RS-485

EXTENSION

MODULE

A

B

C

D

1 2

RUN

PROGRAM

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

3 4 5 6 7 8 9 10 11 12

13

15

14

17

16

18

22

20

19

21

24

23

29

25

27

26

28

32

30 31

L N

-

+

+

T

T

O

O

mA

GND

VLT

SYS

A

B

C

D

PWR

CUR / VLT

A

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

+

mA

TEMP

OUTDOOR

O

O

TEMP

SYSTEM

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

PROVE

/DHW

SHUTDOWN

/SETBACK

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 30VA MAX

INPUT RATINGS:

USE COPPER WIRE,

CLASS 1 WIRE ONLY.

CAUTION

: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

/TSTAT

SYSTEM

M4-CNC

CONDENSING / NON-CONDENSING CONTROL

Condensing

Modulating

Condensing

Modulating

Non-Condensing

Sequencing

Non-Condensing

Sequencing

OD=

25

oF

SYS=

145

oF

<>

B

D

100%

52% ---

---