Boiler stage settings, Mode, Mini-mod – LAARS M4-Ext - Installation Manual User Manual

Page 31: Alert, A b c d, Installation manual 31, Laars modulating controls m4 & m4-ext

Installation Manual

31

• Outdoor Cutoff

The outdoor temperature is above the Outdoor Cutoff setting. No boilers will be active for heating.

• Prove Failure

After boilers have run for some time, Prove signal has ended. All boilers set to Auto or Standby will de-

energize. However, the System relay will remain energized. See "Prove/Domestic Hot Water (DHW)

Priority" on page 19 and "Wiring the Prove" on page 12.

• Purge Delay: 23

A boiler is in purge cycle and the remaining purge time in seconds is 23. See "Purge Delay" on page 24.

• Setback to: 130˚F

The Night Schedule or Setback input is active. Current Setback temperature is 130˚F. See "Setback"

• Shutdown Active

The Shutdown Terminals are Shorted. No boilers will be active. See "Shutdown/Tstat/Setback Mode" on

page 19 and "Wiring the Shutdown, Tstat, or Setback" on page 11.

• Summer

The control is set to Summer. No heat is active. See "Season" on page 22.

• Switch in: 00:30

The switch from one group to the other will take place after 30 minutes. See "Switch Delay" on page 17.

• System Run-On: 46 The System relay is ON for the System Run-On Delay. This example shows that it will remain in System

Run-On for an additional 46 seconds before turning off. See "System Run-On" on page 24.

• Tstat Call

The Tstat Terminals are Shorted. Boilers will be active.

• Waiting for Prove The System relay is ON and the prove terminals are open before the lead boiler relay can energize. See

"Prove/Domestic Hot Water (DHW) Priority" on page 19.

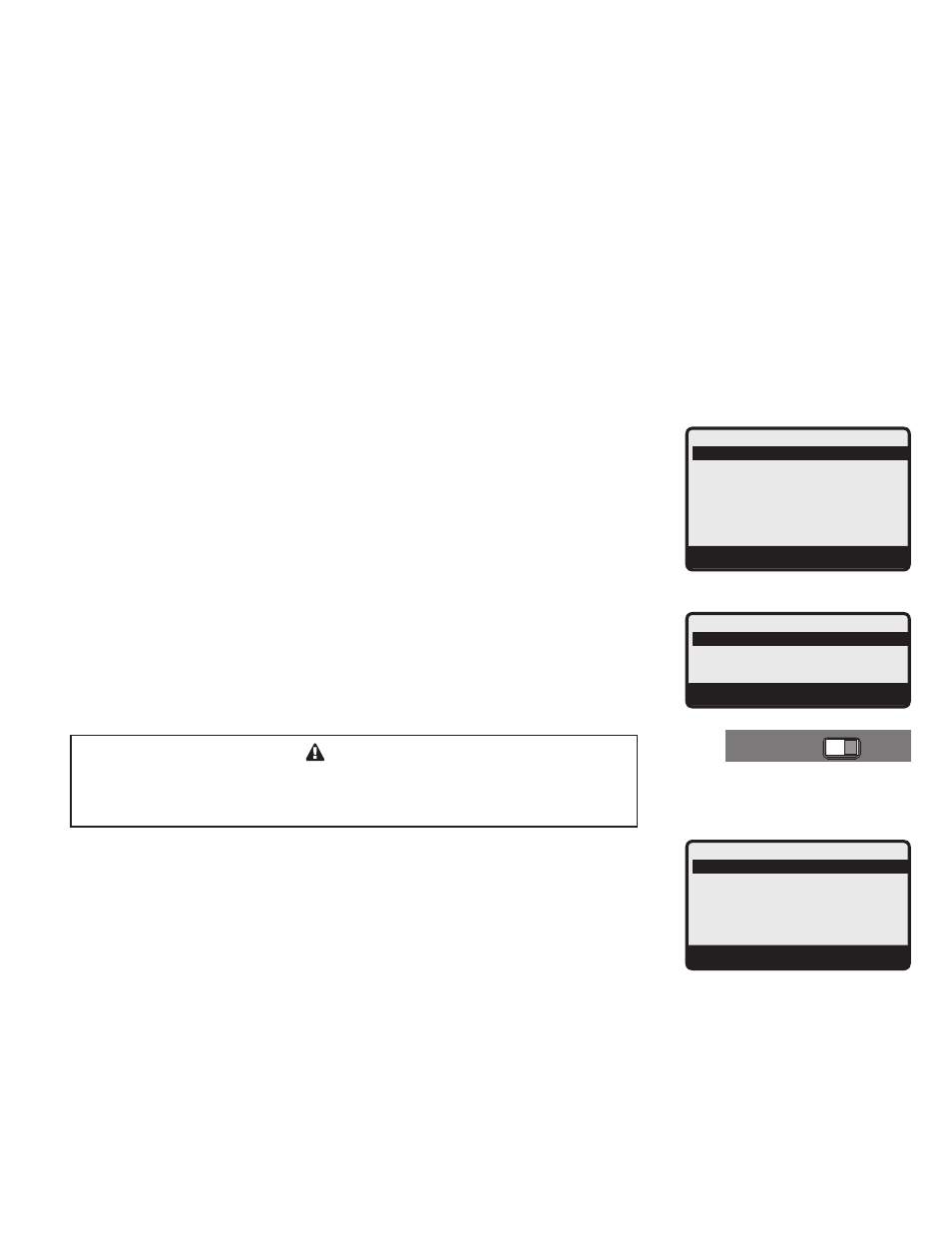

BOiLER STAgE SETTiNgS

Button: STAGE/

The Stage menu offers the capability of adjusting each of the boiler's operation individually.

• In most installations, all active boiler adjustments are the same, but each can be configured

differently if desired.

• If the boilers are not set up properly, the M4-CNC operation may appear to be erratic.

• When the STAGE button is depressed, the Boiler A settings menu will be shown.

• Make all the appropriate settings for Boiler A (See below).

• After completing all the settings for Boiler A (See below), you have the option of copying

these settings to all other modulating boilers. Everything but the Mode -- Auto/Standby/

Manual/Off/On -- will be copied.

• Then select the Next Stage option from the menu to bring up the Boiler B settings menu and

make all the settings. Continue until all boilers have been set.

• If a M4-Extension is connected to the M4-CNC and the stages have been set through the

Startup menu, then scrolling through stages using the Next Stage and Prev Stage menu

options will scroll through the M4-Extension stages as well.

ALERT

To change the

M4-CNC settings, the Program/Run Switch must be set to

Program. The switch is located under the Enclosure Wiring Cover for security.

The Enclosure Wiring Cover can be securely closed using a lock.

Modulating Boiler Stage Menu

STAGE A SETTINGS

Mode

Auto

Ignition %

1%

Mod Start %

80%

Copy Settings

BACK ▲ ▼ SAVE

Sequencing Boiler Stage Menu

STAGE A SETTINGS

Mode

Auto

BACK ▲ ▼ SAVE

SYSTEM

A

B

C

D

Full Modulation Sequencing Control

1 2

RUN

PROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

3 4 5 6 7 8 9 10 11 12

13

15

14

17

16

18

22

20

19

21

24

23

29

25

27

26

28

32

30 31

L N

-

+

+

T

T

O

O

RS-485

mA

GND

VLT

SYS

A

B

C

D

PWR

CUR / VLT

A

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

+

mA

TEMP

OUTDOOR

O

O

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION

: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

Mini-MOD

MOdE

Auto, Standby, Manual, Off, On

Default: Auto

Button: STAGE/Mode

• The M4-CNC only controls the modulation of boilers set to Auto or (after a delay) those

set to Standby. None of the other settings are recommended for output boilers connected to

active units.

• Any stage without an active unit connected must be set to Off.

• The following list describes the MODE options:

Auto

The M4-CNC will control the boiler’s operation to maintain the desired Set Point.

Only boilers set to Auto can be Lead boilers.

Standby Standby boilers can only be activated when all boilers in Auto have been at 100%

modulation or at High fire for the full Standby Time. Standby is generally used

when you want a specific boiler to be available in extreme load conditions. Note

that a Standby boiler Cannot be a Lead boiler.

STAGE A MODE

Auto

Standby

Manual

Off

On

BACK ▲ ▼ SAVE

LAARS Modulating Controls M4 & M4-EXT

HT# 059104-00 B