Connecting to the mini-extension panels, Connecting to the m4-extension panels, Connecting to the xsig – LAARS M4-Ext - Installation Manual User Manual

Page 14: 14 connecting to the m4-extension panels, Laars heating systems, M4-extension a, M4-extension b, M4-cnc module, X sig, M4-ext

14

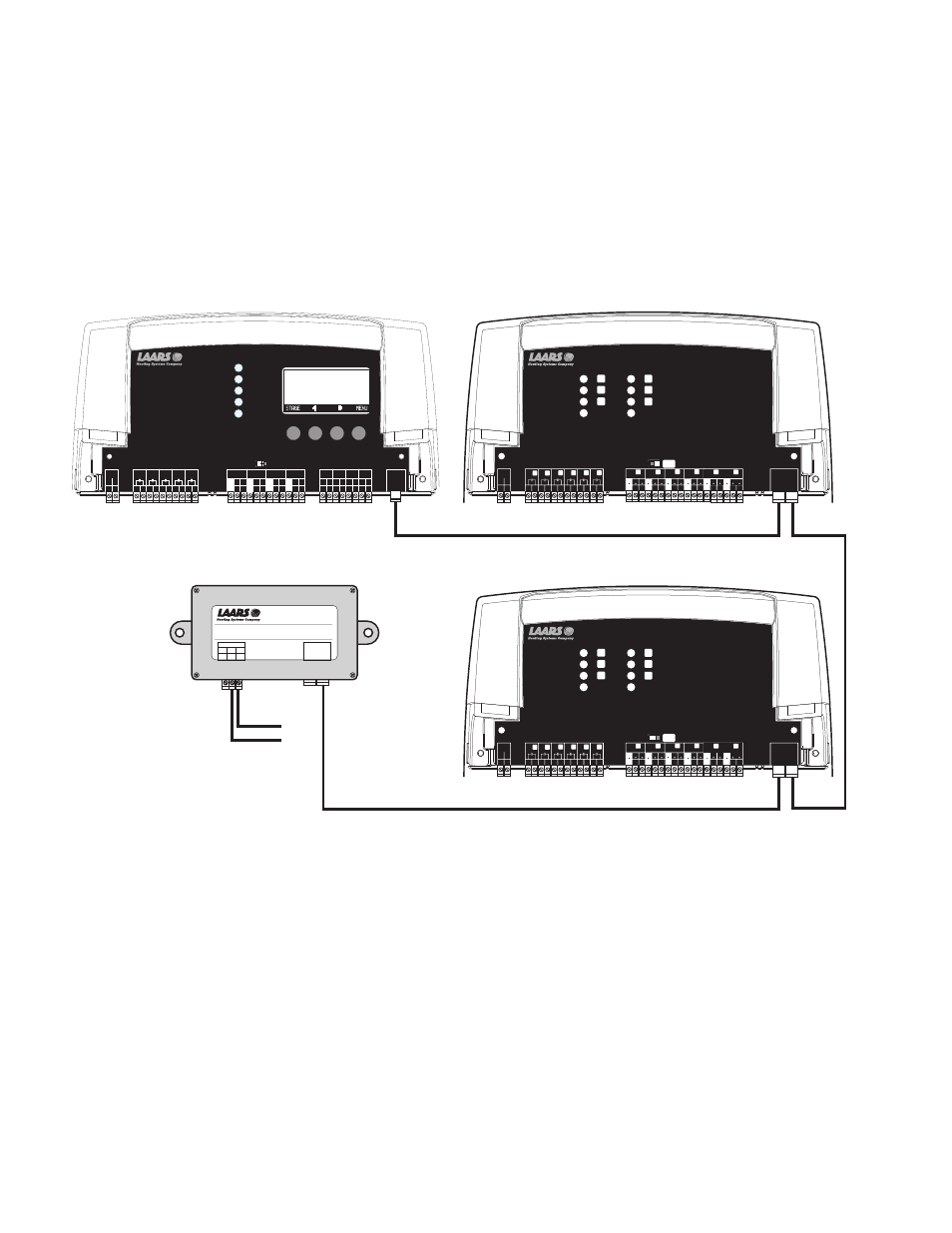

CONNECTiNg TO THE M4-ExTENSiON PANELS

• The M4-CNC is equipped with a 6-pin phone socket (RS485) to connect to extension panels and XSIG (4-20mA remote set point

Inteface). The M4-Extension is equipped with two 6-pin phone sockets to connect to M4-CNC and an additional M4-Extension.

• Set each Extension to a different letter (EXT-A or EXT-B). The M4-CNC will assign the stage letters based on the extension letter

selected.

• Extension A will operate stages E - J and all the LEDs will be Green. However, Extension B will operate stages K - P and all the

LEDs will be Red. See "M4-Extension Layout" on page 5.

• Configure the Modulating and Sequencing Output Types after connecting the Extension panels to be able to configure their outputs.

See "Modulating Output Type" on page 18

• Only use the cable provided for proper operation.

SYSTEM

A

B

C

D

Full Modulation Sequencing Control

1 2

RUN

PROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 30VA MAX

INPUT RATINGS:

USE COPPER WIRE,

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

3 4 5 6 7 8 9 10 11 12

13

15

14

17

16

18

22

20

19

21

24

23

29

25

27

26

28

32

30 31

L N

-

+

+

T

T

O

O

RS-485

mA

GND

VLT

SYS

A

B

C

D

PWR

CUR / VLT

A

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

+

mA

TEMP

OUTDOOR

O

O

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CLASS 1 WIRE ONLY.

PROVE

/DHW

SHUTDOWN

/SETBACK

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

CAUTION

: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

SYSTEM

A

B

C

D

1 2

RUN

PROGRAM

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

3 4 5 6 7 8 9 10 11 12

13

15

14

17

16

18

20

19

21

24

23

29

25

27

26

28

32

30 31

L N

-

+

+

T

T

O

O

RS-485

mA

GND

VLT

SYS

A

B

C

D

PWR

CUR / VLT

A

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

+

+

mA

22

-

GND

VLT

+

mA

TEMP

OUTDOOR

O

O

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 30VA MAX

INPUT RATINGS:

USE COPPER WIRE,

CLASS 1 WIRE ONLY.

CAUTION

: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

F

H

J

Power

CAUTION:

Risk of Electric Shock.

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PWR

L N

1 2

E

3 4

F

5 6

G

7 8

H

9 10

I

11 12

EXTENSION

MODULE

RS-485

Ext A

INPUT RATINGS:

115VAC 60Hz, 12VA MAX

Use Copper Conductors Only.

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY, 15A TOTAL

FOR ALL CIRCUITS

E

G

I

Comm

Ext B

K

M

O

L

N

P

17

16

VLT

mA

CUR / VLT

20

19

16

VLT

mA

GND

CUR / VLT

23

22

19

VLT

mA

GND

CUR / VLT

26

25

22

VLT

mA

GND

CUR / VLT

J

13114

K

M

O

L

N

P

E

F

G

H

K

M

L

N

15

GND

18

GND

21

GND

24

GND

29

28

VLT

mA

CUR / VLT

32

31

16

VLT

mA

GND

CUR / VLT

27

GND

30

GND

I

J

O

P

M4-Extension A

M4-Ext

FULL MODULATION SEQUENCING EXTENSION

F

H

J

Power

CAUTION:

Risk of Electric Shock.

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PWR

L N

1 2

E

3 4

F

5 6

G

7 8

H

9 10

I

11 12

EXTENSION

MODULE

RS-485

Ext A

INPUT RATINGS:

115VAC 60Hz, 12VA MAX

Use Copper Conductors Only.

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY, 15A TOTAL

FOR ALL CIRCUITS

E

G

I

Comm

Ext B

K

M

O

L

N

P

17

16

VLT

mA

CUR / VLT

20

19

16

VLT

mA

GND

CUR / VLT

23

22

19

VLT

mA

GND

CUR / VLT

26

25

22

VLT

mA

GND

CUR / VLT

J

13 14

K

M

O

L

N

P

E

F

G

H

K

M

L

N

15

GND

18

GND

21

GND

24

GND

29

28

VLT

mA

CUR / VLT

32

31

16

VLT

mA

GND

CUR / VLT

27

GND

30

GND

I

J

O

P

M4-Extension B

M4-Ext

FULL MODULATION SEQUENCING EXTENSION

Connecting M4-CNC to

Two M4-Extension

Panels and XSIG

M4-CNC Module

M4-CNC

CONDENSING AND NON-CONDENSING

Cable provided with Extension or 4-20mA EMS Interface

Cable provided with Extension or 4-20mA EMS Interface

4-20 mA EMS

4-20mA INPUT

+

Signal GND

1

2

3

RS485

EXTENSION

CONNECTORS

X SIG

(-)

EMS/BMS Sources

Excitation Voltage

(+)

EMS/BMS

Temperature

Set PointInput

OD=

25

o

F

SYS=

145

o

F

<>

B

D

100%

52% ---

---

CONNECTiNg TO THE xSig

• The M4-CNC is equipped with a 6-pin phone socket (RS485) to connect to extension panels and XSIG (4-20mA remote set point

Inteface). The XSIG is equipped with two 6-pin phone sockets to connect to M4-CNC and an additional M4-Extension.

• Set Sensor Type to either of the two EMS options. See "Sensor Type" on page 16.

• The interface must be ordered separately.

• Only use the cable provided for proper operation.

LAARS Heating Systems

HT# 059104-00 B