Mini-mod-cnc overview, M4-cnc overview, Switch mode = target temperature – LAARS M4-Ext - Installation Manual User Manual

Page 3: Switch mode = outdoor temperature, Outdoor temp

Installation Manual

3

M4-CNC OvERviEW

In response to new advancement in condensing boiler design and size, many applications utilize multiple condensing boilers in

addition to the non-condensing boilers. That triggered Laars design of the M4-CNC. It is intended to manage the two groups of

boilers to maximize system efficiency at the lowest operating cost while maintaining the desired comfort. The M4-CNC operates each

group based on the Target temperature switching set point.

Depending on the actual Target Temperature, the M4-CNC will determine which group of boilers will be the lead and which group

will be the lag group. The Condensing Group of boilers will be the Lead group when the Target Temperature is below the Switching

Set Point. However, when the Target Temperature rises above the Switching Set Point, the Non-Condensing Boiler Group will be the

lead group and the Condensing Group will be the lag group.

Basically, the M4-CNC will allow the condensing group of boilers to operate as along as the Target Temperature is below the

Switching Set Point. See "Switch Set Point" on page 16. During that period, if additional output boilers are needed, the M4-CNC will

energize the non-condensing boilers to meet the load. See "Heavy Load Sequence 2nd Group" on page 17. When less output is required

the M4-CNC will de-energize the non-condensing boilers prior to de-energizing the condensing boilers.

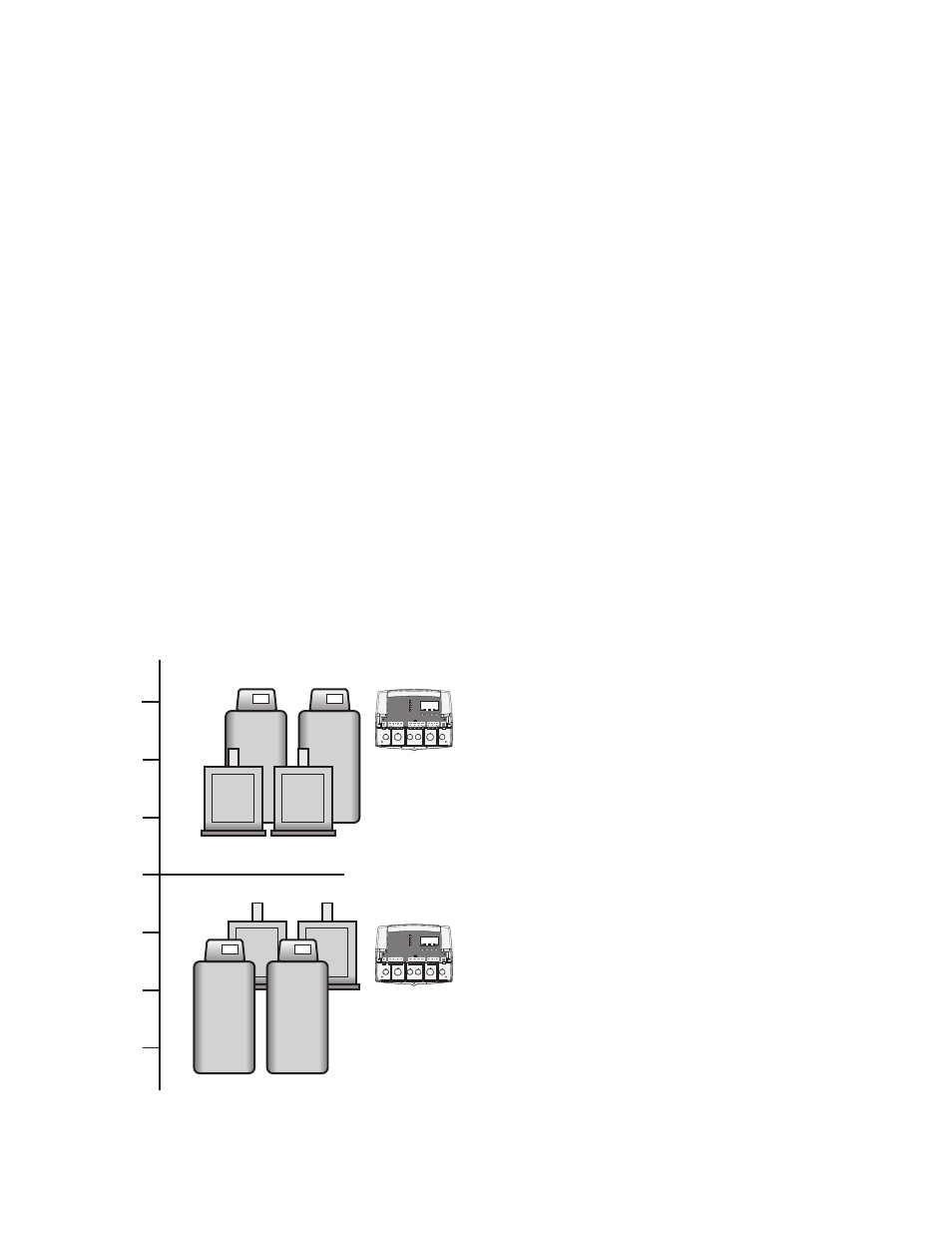

Above the Switch Set Point

Non-Condensing are the Lead Group

Condensing are the Lag Group

Target Switch

Set Point

= 120°F

Below the Switch Set Point

Condensing are the Lead Group

Non-Condensing are the Lag Group

120°F

140°F

100°F

SWITCH MODE = Target Temperature

SYSTEM

A

B

C

D

Condensing / Non-Condensing Control

1 2

RUN

PROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

3 4 5 6 7 8 9 10 11 12

13

15

14

17

16

18

22

20

19

21

24

23

29

25

27

26

28

32

30 31

L N

-

+

+

T

T

O

O

RS-485

mA

GND

VLT

SYS

A

B

C

D

PWR

CUR / VLT

A

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

+

mA

TEMP

OUTDOOR

O

O

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

OD=

25oF

SYS=

145oF

<>

B

100%

52%

COND

COND

NON-

COND

NON-

COND

NON-

COND

NON-

COND

COND

COND

SYSTEM

A

B

C

D

Condensing / Non-Condensing Control

1 2

RUN

PROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

3 4 5 6 7 8 9 10 11 12

13

15

14

17

16

18

22

20

19

21

24

23

29

25

27

26

28

32

30 31

L N

-

+

+

T

T

O

O

RS-485

mA

GND

VLT

SYS

A

B

C

D

PWR

CUR / VLT

A

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

+

mA

TEMP

OUTDOOR

O

O

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

OD=

25oF

SYS=

145oF

<>

B

100%

52%

Target

Temp

Above the Switch Set Point

Condensing are the Lead Group

Non-Condensing are the Lag Group

Outdoor Switch

Set Point

= 30°F

Below the Switch Set Point

Non-Condensing are the Lead Group

Condensing are the Lag Group

30°F

50°F

10°F

SWITCH MODE = Outdoor Temperature

COND

COND

NON-

COND

NON-

COND

NON-

COND

NON-

COND

COND

COND

SYSTEM

A

B

C

D

Condensing / Non-Condensing Control

1 2

RUN

PROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

3 4 5 6 7 8 9 10 11 12

13

15

14

17

16

18

22

20

19

21

24

23

29

25

27

26

28

32

30 31

L N

-

+

+

T

T

O

O

RS-485

mA

GND

VLT

SYS

A

B

C

D

PWR

CUR / VLT

A

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

+

mA

TEMP

OUTDOOR

O

O

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

OD=

25oF

SYS=

145oF

<>

B

100%

52%

SYSTEM

A

B

C

D

Condensing / Non-Condensing Control

1 2

RUN

PROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

3 4 5 6 7 8 9 10 11 12

13

15

14

17

16

18

22

20

19

21

24

23

29

25

27

26

28

32

30 31

L N

-

+

+

T

T

O

O

RS-485

mA

GND

VLT

SYS

A

B

C

D

PWR

CUR / VLT

A

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

+

mA

TEMP

OUTDOOR

O

O

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

OD=

25oF

SYS=

145oF

<>

B

100%

52%

Outdoor

Temp

LAARS Modulating Controls M4 & M4-EXT

HT# 059104-00 B