Wiring, Wiring the power, Wiring the sensors – LAARS M4-Ext - Installation Manual User Manual

Page 11: Wiring the shutdown, tstat, or setback, Warning, Mini-mod-cnc, Installation manual 11, Laars modulating controls m4 & m4-ext, Terminals 31, 32), A b c d

Installation Manual

11

WiRiNg

• All wiring must enter the enclosure through the bottom knockouts.

• Class 1 voltage wiring must utilize a different knockout and conduit from any Class 2 voltage wiring.

WiRiNg THE POWER

(TERMinALS 1, 2)

• Bring the 120VAC 60Hz power wires through the bottom left knockout of the enclosure.

• Connect the hot line to terminal marked L.

• Connect the neutral line to the terminal marked N.

• Laars recommends installing a surge suppressor on the power source to the M4-CNC.

WARNiNg

Class 1 voltages must enter the enclosure through a different opening from any Class 2 voltage wiring.

Laars recommends installing a surge suppressor on the power source to the M4-CNC.

SYSTEM

A

B

C

D

Condensing / Non-Condensing Control

1 2

RUN

PROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

3 4 5 6 7 8 9 10 11 12

13

15

14

17

16

18

22

20

19

21

24

23

29

25

27

26

28

32

30 31

L N

-

+

+

T

T

O

O

RS-485

mA

GND

VLT

SYS

A

B

C

D

PWR

CUR / VLT

A

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

+

mA

TEMP

OUTDOOR

O

O

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

OD=

25

o

F

SYS=

145

o

F

<>

B

100%

52%

Mini-MOD-CNC

Line

Neutral

120VAC

Power Source

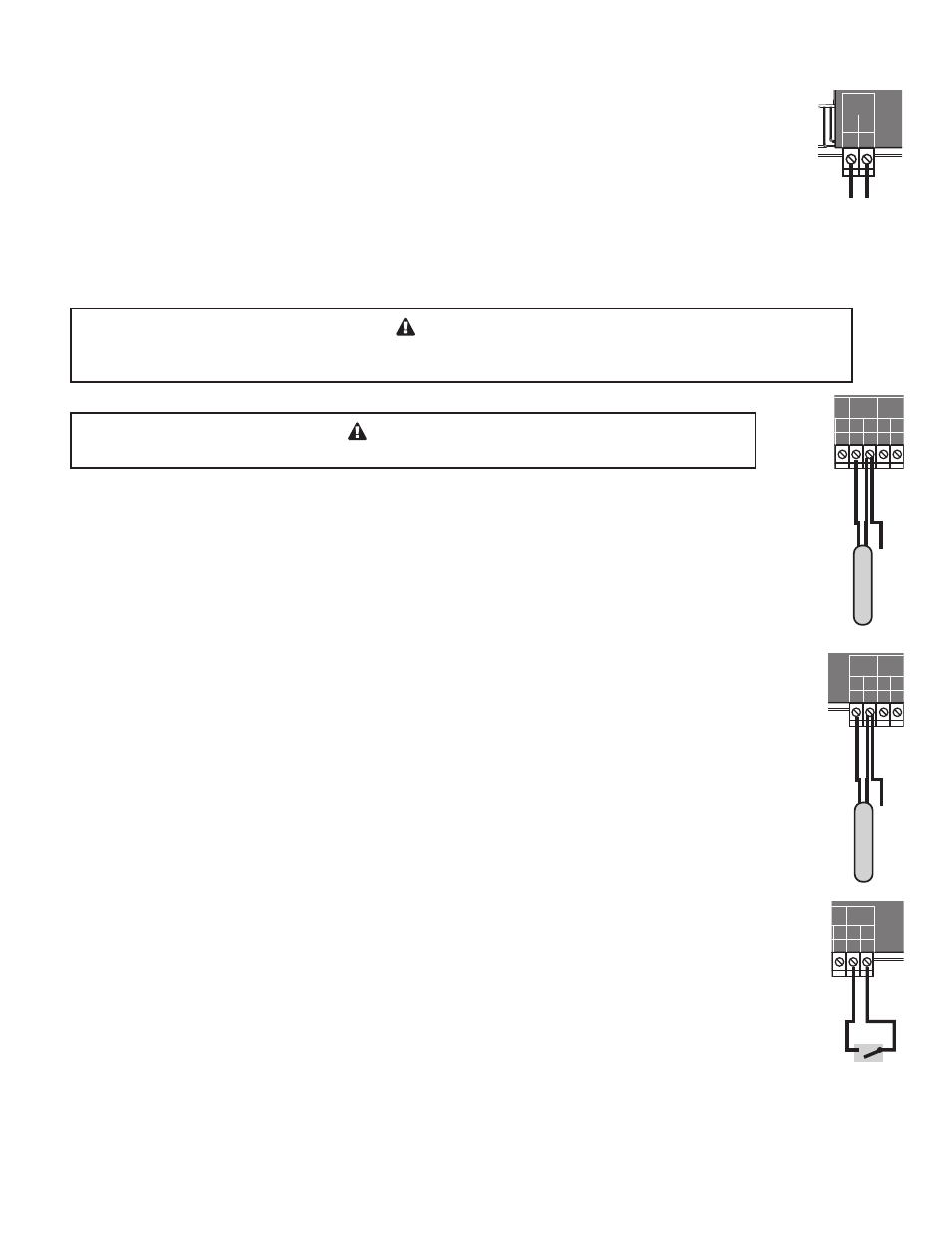

WiRiNg THE SENSORS

WARNiNg

Connect the shield at the control terminal end and cut the shield wire at the sensor end.

SYSTEM SENSOR WiRiNg

(TERMinALS 27, 28)

• A M4-CNC must be connected to a System temperature sensor (CA002400 or equivalent) located in the common

header. The sensor must be inserted in a 3/8 ID well (CA002500 or equivalent).

• Temperature sensor wires can be extended up to 500’ by splicing its wires with a shielded 2-conductor cable

(Belden #8760 or equivalent (#18/2)).

• Temperature sensors have no polarity. Connect the two wires from the sensor to the M4-CNC terminals marked

SYSTEM TEMP 27, 28.

• Connect the sensor shield to the circled terminal 28 with one of the sensor wires.

SYSTEM

A

B

C

D

Condensing / Non-Condensing Control

1 2

RUN

PROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

3 4 5 6 7 8 9 10 11 12

13

15

14

17

16

18

22

20

19

21

24

23

29

25

27

26

28

32

30 31

L N

-

+

+

T

T

O

O

RS-485

mA

GND

VLT

SYS

A

B

C

D

PWR

CUR / VLT

A

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

+

mA

TEMP

OUTDOOR

O

O

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

OD=

25

o

F

SYS=

145

o

F

<>

B

100%

52%

Mini-MOD-CNC

System Sensor

Sensor Shield

SYSTEM

A

B

C

D

Condensing / Non-Condensing Control

1 2

RUN

PROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

3 4 5 6 7 8 9 10 11 12

13

15

14

17

16

18

22

20

19

21

24

23

29

25

27

26

28

32

30 31

L N

-

+

+

T

T

O

O

RS-485

mA

GND

VLT

SYS

A

B

C

D

PWR

CUR / VLT

A

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

+

mA

TEMP

OUTDOOR

O

O

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

OD=

25

o

F

SYS=

145

o

F

<>

B

100%

52%

Mini-MOD-CNC

Outdoor Sensor

Sensor Shield

OUTdOOR SENSOR WiRiNg

(TERMinALS 25, 26)

• The M4-CNC will vary the system Set Point based on outdoor temperature. In addition, the outdoor sensor is used

as an Outdoor Cutoff. The M4-CNC will disable all boilers when the outdoor temperature is above the adjustable

Outdoor Cutoff temperature.

• For an outdoor sensor use the outdoor sensor provided (CA006500).

• The sensor wires can be extended up to 500’ using shielded 2-conductor cable (Belden #8760 or equivalent (#18/2)).

• Temperature sensors have no polarity. Connect the wires from the outdoor sensor to the M4-CNC terminals marked

OUTDOOR TEMP - 25, 26.

• Connect the shield to the circled terminal 26 with one of the sensor wires.

WiRiNg THE SHUTdOWN, TSTAT, OR SETBACk

(TERMinALS 31, 32)

• The Shutdown will be available when selected as the Shutdown/Tstat/Setback mode from the Startup menu. See

"Shutdown/Tstat/Setback Mode" on page 19. This will provide the user with an adjustable Day/Night Schedule. See

"Day/Night Schedules" on page 28.

• The Shutdown feature can be used whenever it is desirable to turn off the M4-CNC stage outputs from a remote

location or another controller (i.e. EMS input).

• The Tstat option, when selected from the Shutdown/Tstat/Setback startup menu, offer the capability of controlling

the operation of the M4-CNC based on a thermostat input. This will provide the user with an adjustable Day/Night

Schedule.

• The thermostat will send the M4-CNC a call for heat by shorting terminals 31 and 32.

SYSTEM

A

B

C

D

Condensing / Non-Condensing Control

1 2

RUN

PROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 12VA MAX

INPUT RATINGS:

USE COPPER CONDUCTORS ONLY

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

3 4 5 6 7 8 9 10 11 12

13

15

14

17

16

18

22

20

19

21

24

23

29

25

27

26

28

32

30 31

L N

-

+

+

T

T

O

O

RS-485

mA

GND

VLT

SYS

A

B

C

D

PWR

CUR / VLT

A

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

+

mA

TEMP

OUTDOOR

O

O

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

PROVE

/DHW

SHUTDOWN

/TSTAT

/SETBACK

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

OD=

25

o

F

SYS=

145

o

F

<>

B

100%

52%

Mini-MOD-CNC

Shutdown,

T-Stat, or

Setback Signal

LAARS Modulating Controls M4 & M4-EXT

HT# 059104-00 B