3a. combustion air supply – LAARS Mini-Therm JVS (Sizes 50-225) - Install and Operating Manual User Manual

Page 9

Mini-Therm JV

Page 9

Boiler Size

Outside Air Area

Inside Air Area

sq. in

sq. cm

sq. in.

sq. cm

50

15

97

100

645

75

20

129

100

645

100

25

161

100

645

125

32

206

125

807

160

40

258

160

1032

225

60

387

225

1452

*Area indicated is for one of two openings: one at floor level

and one at the ceiling, so the total net free area would be

double the figures shown. For special conditions, refer to

NFPA54 ANSI Z223.1. In Canada, refer to the National

Standard CAN1-B149.1 or .2, which differs from this table.

NOTE: Check with louver manufacturers for Net Free Area of

Louvers. Correct for screen resistance to the Net Free Area if a

screen is used.

Table 3. Minimum Recommended

Air Supply to Boiler Room

Exhaust Fans or Vents: Any equipment which

exhausts air from the boiler room can deplete the

combustion air supply or reverse the natural draft

action of venting system. This could cause flue

products to accumulate in the boiler room. Additional

air must be supplied to compensate for such exhaust.

The information in Table 3 is not applicable in

installations where exhaust fans or blowers of any

type are used. Such installations must be designed by

qualified engineers.

If a blower or fan is used to supply air to the boiler

room, the installer should make sure it does not create

drafts which could cause nuisance shutdowns. If a

blower is necessary to provide adequate combustion

air to the boiler, a suitable switch or equivalent must

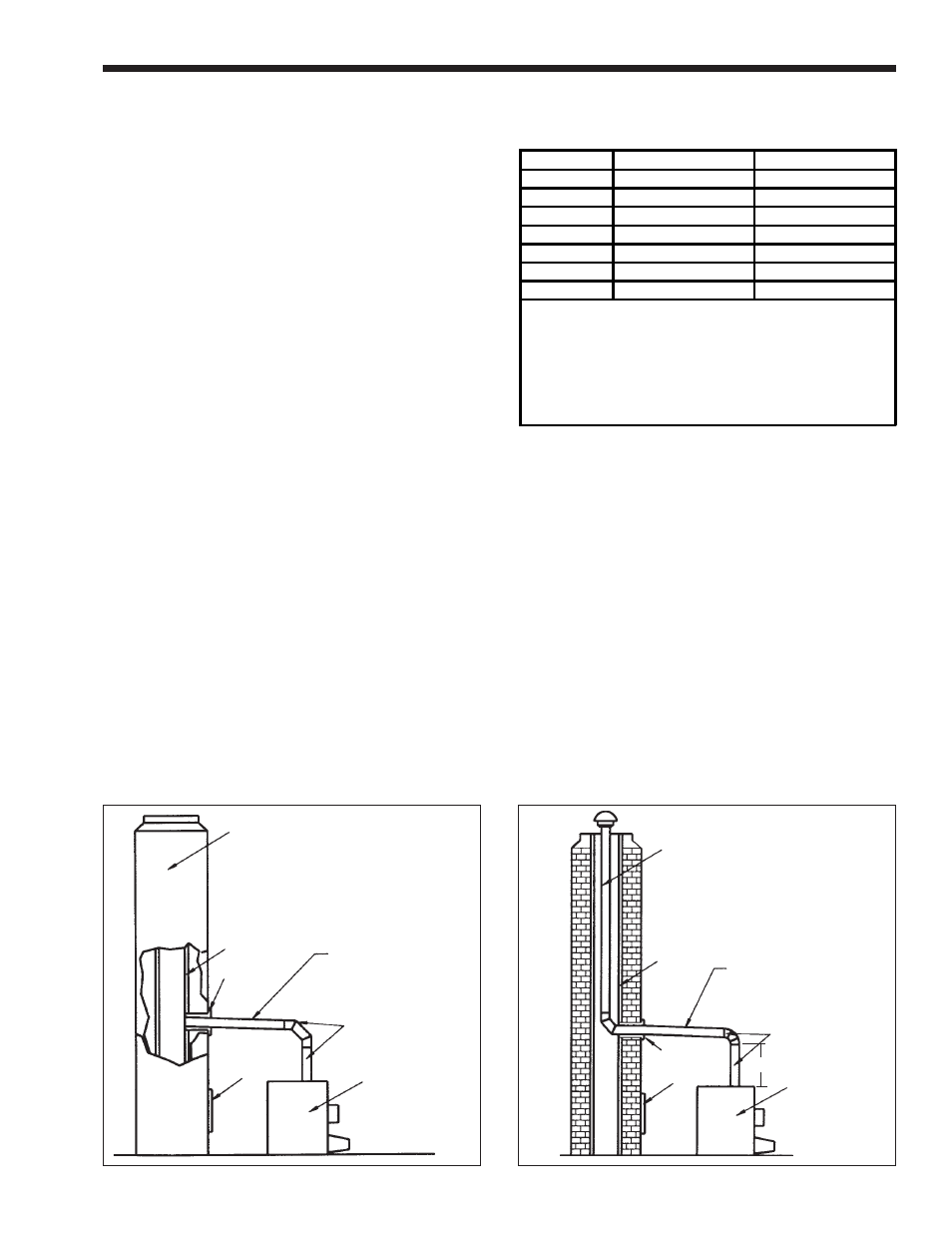

Figure 3. Chimney Venting.

Figure 4. Vertical Venting.

CHIMNEY

LINER

THIMBLE

VENT

SYSTEM

BOILER

CLEANOUT

CHIMNEY

LINER

VENT

SYSTEM

BOILER

CLEANOUT

THIMBLE

1/4"

PER FT.

(20mm PER M)

SLOPE

1/4"

PER FT.

(20mm PER M)

SLOPE

12" (305mm)

SECTION 3.

Air and Venting

3A. Combustion Air Supply

The boiler location must provide sufficient air

supply for proper combustion, and ventilation of

the surrounding area as outlined in the latest edition

of U.S. ANSI standard Z223.1 or in Canada, CAN/

CGA-B149.1 or .2, and any local codes that may be

applicable.

In general, these requirements specify that the

boiler rooms which represent confined spaces should

be provided with two permanent air supply openings;

one within 12 inches (305mm) of the ceiling, the other

within 12 inches (305mm) of the floor.

NOTE: In Canada, follow Canadian Standard,

CAN/CGA-B149 or local codes.

Outside Air Supply: When combustion air is

supplied directly through an outside wall, each

opening should have a minimum free area of one

square inch per 4,000 BTU/h (6 sq. cm per 1.2 kW)

input of the total input rating of all appliances in the

enclosed area.

Inside Air Supply: When combustion is supplied

from inside the building, each opening should have

a minimum free area of one square inch per 1,000

BTU/h (6 sq. cm per 0.3 kW) input of the total input

rating of all appliances in the enclosed area. These

openings should never be less than 100 square inches

(645 sq. cm).