LAARS Mini-Therm JVS (Sizes 50-225) - Install and Operating Manual User Manual

Page 17

Mini-Therm JV

Page 17

5B By-pass Piping

The following information and suggestions are made

on by-pass piping as it affects the temperature rise

at the boiler. A boiler temperature rise must be taken

on all JV boiler installations. If the temperature rise

exceeds 30°F (17°C) at full rate, it is an indication that

the boiler is not receiving adequate water flow. Check

the pump for any obstruction, replace the pump with a

larger size where necessary, or install a system by-pass

as indicated in Figures 10 and 11.

A full sized, 1¼" bypass with balancing valves is

strongly recommended for all systems, and required

when: 1) the boiler is installed without primary-

secondary piping in a multiple zone system; 2) when

the return water temperature can be expected to be

lower than 120°F (44°C); or 3) whenever the system

piping on the outlet side of the boiler may allow

reduced flow through the heat exchanger, causing

excessive temperature rise (see Section 5.2).

Note: Laars strongly recommends a primary/

secondary piping system for all installations, especially

sizes 125, 160 and 225. In this system, a circulator is

dedicated to pumping the boiler only. This circulator

should be sized for the boiler head loss and flow rate.

All precautions must be taken by the installer to insure

that a maximum temperature rise through the boiler

does not exceed 30°F (17°C). The temperature rise

on boilers installed in multi-zone systems using zone

valves must be taken when the zone of the longest

length and/or the zone of the highest head loss is open.

A full size, 1¼" diameter by-pass with

balancing valve must be installed if a return water

temperature below 120°F (44°C) is expected under

operating conditions regardless of boiler size. This

may be expected in many systems, including in-

floor radiant and snow melt systems.

5C Adjusting the bypass:

Refer to Figure 11. Provide a means of measuring

temperature on the inlet pipe to the boiler such as

using a strap on or infrared thermometer. Starting

with both balancing valves fully open, start the boiler.

Adjust the balancing valve on the return to the system

slowly to provide 120°F (44°C) water at the inlet to

the boiler, leaving the bypass balancing valve fully

open. As the system warms up, this valve may need

to be adjusted open. In rare cases, this valve will have

to be kept fully open, and the bypass balancing valve

adjusted toward closed to prevent heated bypass water

from satisfying the call for heat when the system is up

to temperature.

5D Alternate Auto-Bypass Operation

Use of the Laars thermostatic union, p/n 2400-030,

can provide automatic bypass operation in primary

- secondary piped systems (but cannot be used

when primary - secondary piping is not used). The

thermostatic union is installed on the outlet piping,

after the bypass assembly. It can be used in place of a

balancing valve. It opens fully at 140°F

(see Figure 11). Contact the factory for more

information.

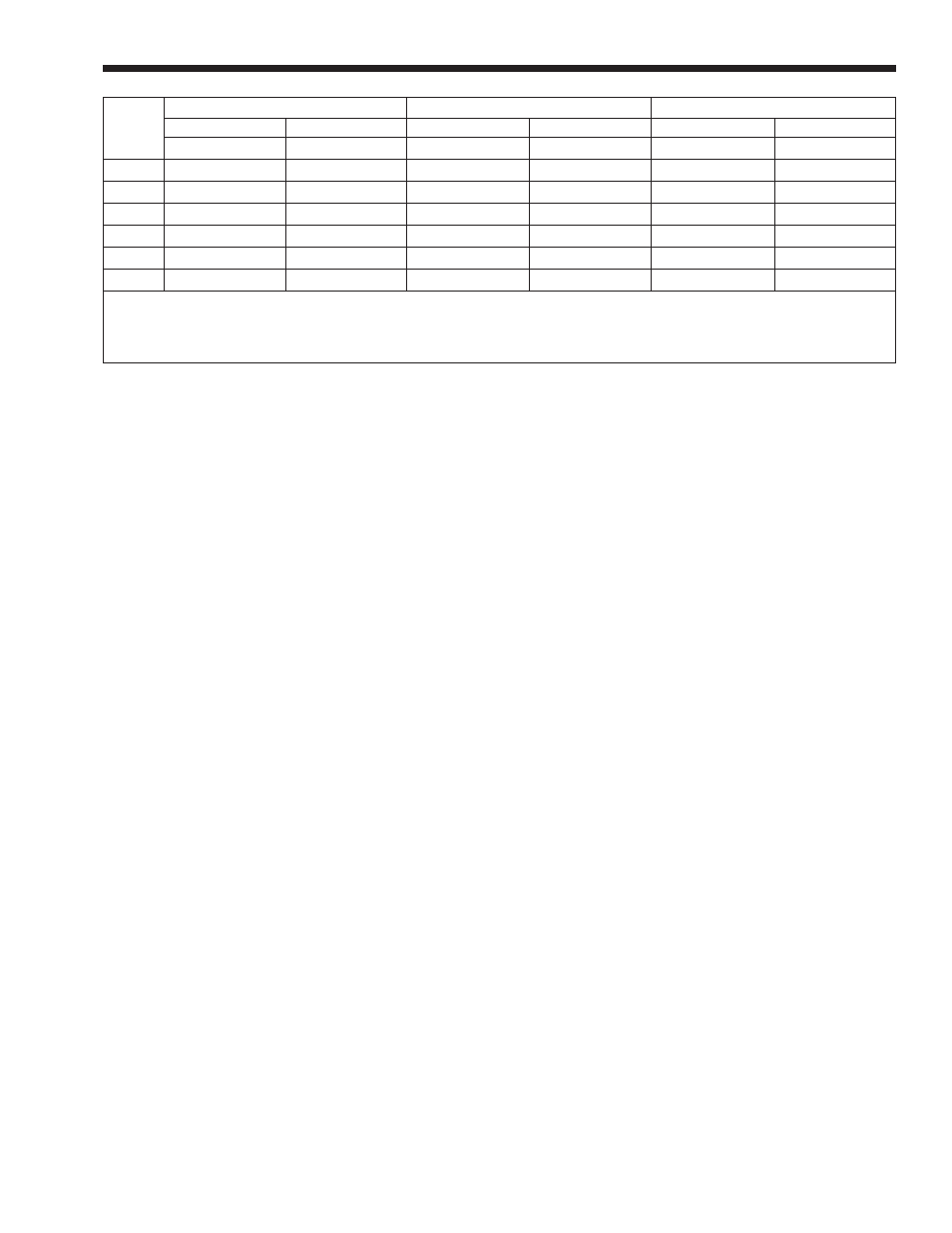

Table 7. Temperature Rise °F °C.

gpm = Water Flow in gallons per minute. l/s = Water flow in liters per second.

ft = Pressure drop (headloss) through the boiler in feet of water. m = Pressure drop (headloss) through the boiler in meters of water.

Notes: 1. Shaded area is the recommended flow and temperature rise.

2. Temperature rise and associated flow rates are based on high fire operation at the Normal Input Rate from the rating plate.

15°F 8°C

20°F 11°C

25°F 14°C

Size

Flow Rate

Headloss

Flow Rate

Headloss

Flow Rate

Headloss

gpm

l/s

ft

m

gpm

l/s

ft

m

gpm

l/s

ft

m

50

5.3

0.3

0.3

0.1 4 0.3

0.2

0.1

3.2

0.2

0.1

0

75

8

0.5

0.6

0.2

6

0.4

0.3

0.1

4.8

0.3

0.2

0.1

100

10.7

0.7

1.3

0.4

8

0.5

0.7

0.2

6.4

0.4

0.5

0.2

125

13.3

0.8

2.2

0.7 10 0.6

1.3

0.4

8

0.5

0.8

0.2

160

17

1.1

2.5

0.8

12.8

0.8

1.8

0.5

10.2

0.6

1.2

0.4

225

24

1.5 5 1.5

18

1.1

3.1

0.9

14.4

0.9

1.9

0.6