LAARS Mini-Therm JVS (Sizes 50-225) - Install and Operating Manual User Manual

Page 33

Mini-Therm JV

Page 33

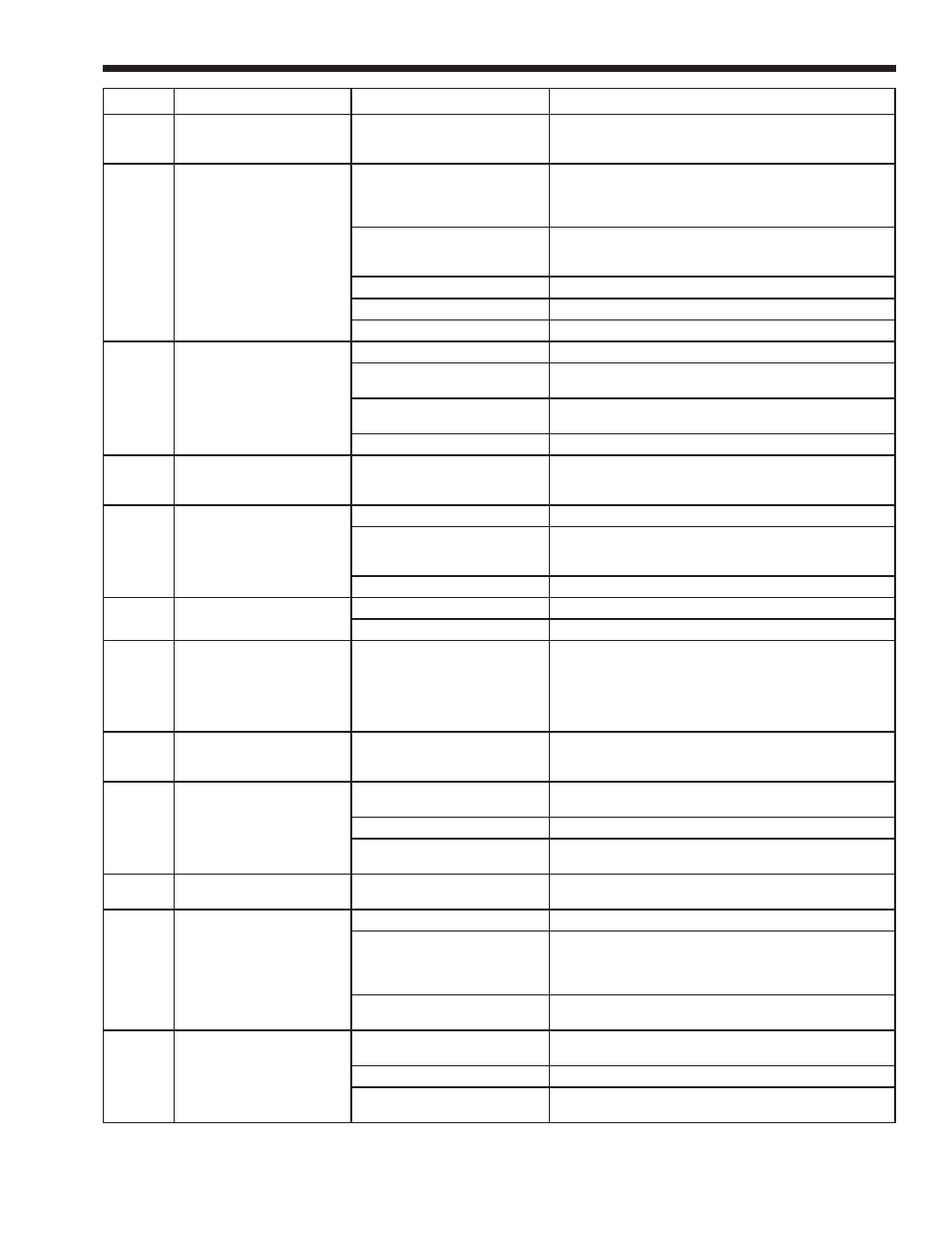

#

Symptom

Cause

Remedy

1

Pump not operating

No power . . . . .

Pump defective . . . . .

Incorrectly wired . . . . .

Check circuit breakers and power source. Replace. Recheck

wiring diagrams.

2

Pilot outage

Inlet gas pressure too low . . . . .

Consult gas utility company. Inlet gas pressure to boiler

should be 5.5" (1.4 kPa) to 9.0" (2.2 kPa) water column on

natural gas. 10.0" (2.5k Pa) to 14.0" (3.4 kPa) on propane

gas.

Inlet gas pressure to high

causing an unstable blowing

pilot. . . . .

Pressure should be regulated within limits shown above.

Damaged pilot. . . .

Replace.

Dirty pilot. . . .

Blow dust or lint out of pilot.

Plugged or undersized pilot. . . . Replace pilot orifice.

3

Flame roll-out on start-up

Blocked outlet

Check flue damper operation.

Pilot out of position (delayed

ignition) . . . .

Correct pilot position.

Blocked heat exchanger or flue

. . . . .

Clean and correct as necessary.

Refractory tile out of place . . . . .

Correct or replace tile as necessary.

4

Flame has lazy yellow tip

Low primary air . . . .

Correct manifold pressure according to rating plate. Correct

orifice size if necessary (see parts list). Clean burner ports

if dirty.

5

Not enough heat

Inadequate gas supply . . . . .

Gas meter too small. Gas line from meter to boiler too small.

Low manifold gas pressure . . . . . Gas pressure on boiler manifold, with Modusnap valve wide

open. Should be adjusted to 4.0" (1.0 kPa) W.C. natural gas

9.0" (2.2 kPa) W.C. propane.,

Boiler size inadequate . . . . .

Replace with boiler of higher input.

6

Pump noisy

Air in volute . . . . .

Bleed air from volute. Check pump alignment.

Worn coupling or bearings . . . . .

Replace worn parts.

7

Boiler pounding or knocking

Too low water flow through boiler

. . . . .

Check temperature rise between inlet and outlet boiler

piping. 15°F (8°C) to 25°F (14°C) temperature rise is

recommended. If temperature rise is over 25°F (14°C),

increase pipe size or pump capacity or locate obstruction.

Check for stuck closed zone valves. Check for zone pumps

not operating. Check for closed valve in system.

8

Boiler condensing

Low water temperature . . . . .

Flue product moisture will condense at the start-up until

the boiler water temperature reaches the normal operating

conditions.

9

Pump cavities or low water

pressure at boiler gauge or

bubbles in system at high

temperature

Defective fill valves or pressure

regulator .

Replace.

Oversized expansion tank . . . . .

Replace.

Expansion tank piped incorrectly

. . . . .

Re-pipe expansion tank to suction size of pump at high

temperature.

10

Pressure relief valve opens

Waterlogged expansion tank . . . . Drain 2/3 of the water from the expansion

tank.

11

Pilot is lit but main burners

will not come on

Boiler off on hi-limit control . . . . .

Check for low water flow or hi-limit setting.

Boiler incorrectly wired . . . . .

On single or multiple zone systems with zone valves, room

thermostat should be wired to T-T terminals. For multiple

zone systems with ozone pumps, thermostats for extra

zones should be wired to R&A terminals.

Broken wire in thermostat circuit

or defective thermostat . . .

Check continuity through thermostat circuit with

12

Boiler short cycles

Heat anticipator in room

thermostat set too low . . . . .

Increase setting (1.0 is usually satisfactory)

Low water flow through boiler . .

Increase size of pump or increase piping size.

Hi-limit switch may be set too

low . . . .

Increase setting to at least 20°F (11°C) over outlet water

temperature.