Wiring the boilers, Wiring boiler activation or on/off staging boilers, Wiring multi-stage boilers – LAARS M4-LHS - Installation Manual User Manual

Page 14: Wiring to modulating boilers, Wiring the 4-20ma modulating boilers, Wiring voltage modulating boilers, M4-lhs, Warning, Multi-stage boiler, Modulating boiler (modulating boiler type)

HT# 059295-00

A

14

M4-LHS installation and Operation Manual

Wiring the Boilers

• When wiring Condensing and Non-Condensing boilers make sure that the Condensing boilers use the first

stages and the Non-Condensing boilers use the following stages. That is, if the installation had two Condensing

Modulating boilers and two Non-Condensing Staging On/Off boilers, Stage A and B must be used by the

Condensing boilers while Stage C and D must be used by the Non-Condensing boilers.

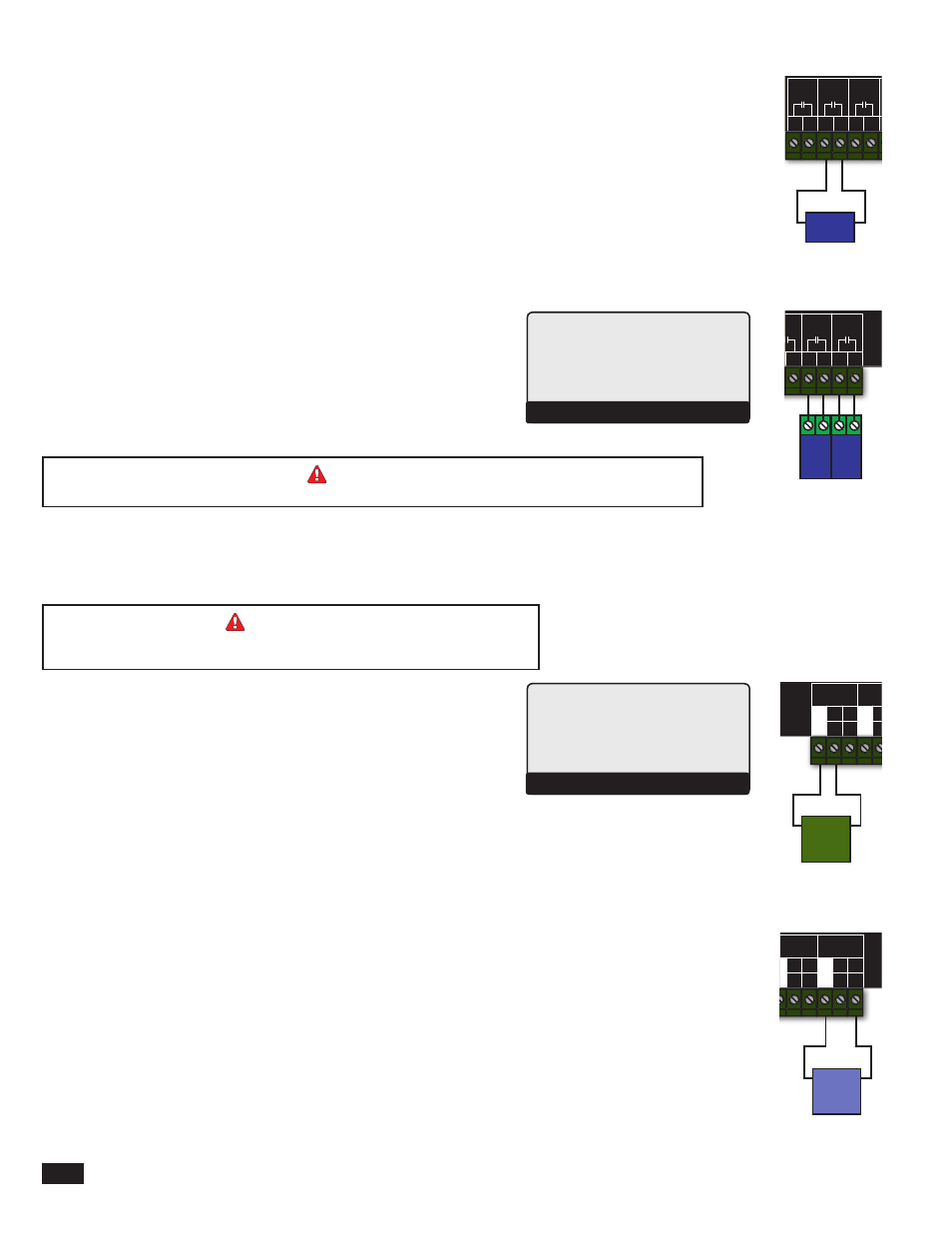

Wiring Boiler activation or On/Off Staging Boilers

(A Terminals 5, 6), (B Terminals 7, 8), ...

• Each boiler output has a Normally Open (N.O.) dry-contact relay. They do not source any power.

• Wire the N.O. relay contacts in series with the unit’s limit circuit.

• Note that some modulating boilers may not require the use of these outputs.

Boiler Enable

Output

Boiler

SYSTEM

A

B

C

D

1 2

RUN

PROGRAM

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

3 4 5 6 7 8 9 10 11 12

13

15

14

17

16

18

20

19

21

24

23

29

25

27

26

28

32

30 31

L N

-

+

+

T

T

O

O

RS-485

mA

GND

VLT

SYS

A

B

C

D

PWR

CUR / VLT

A

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

+

+

mA

22

-

GND

VLT

+

mA

TEMP

OUTDOOR

O

O

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

PROVE

/DHW

SHUTDOWN

/SETBACK

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 30VA MAX

INPUT RATINGS:

USE COPPER WIRE,

CLASS 1 WIRE ONLY.

CAUTION

: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

/TSTAT

M4-LHS

HYBRID CONTROL

Wiring Multi-Stage Boilers

(For Staging Boiler Types Only) See Page 19

• Each stage on a multi-stage boiler must use one of the N.O. relays.

• Note that on the display of the M4-LHS each multi-stage boiler will

consist of a multiple letters.

• Each stage output has one Normally Open (N.O.) relay contact that

does not source any power.

WarNiNg

Class 1 voltages must enter the enclosure through a different opening from any Class 2 voltage wiring.

OD=

55

o

F SYS=

142

o

F

<

CD

HI

LOW

STAGE ◄ ► MENU

Multi-Stage Boiler

2-Stage Boiler

Low

High

SYSTEM

A

B

C

D

1 2

RUN

PROGRAM

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

3 4 5 6 7 8 9 10 11 12

13

15

14

17

16

18

20

19

21

24

23

29

25

27

26

28

32

30 31

L N

-

+

+

T

T

O

O

RS-485

mA

GND

VLT

SYS

A

B

C

D

PWR

CUR / VLT

A

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

+

+

mA

22

-

GND

VLT

+

mA

TEMP

OUTDOOR

O

O

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

PROVE

/DHW

SHUTDOWN

/SETBACK

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 30VA MAX

INPUT RATINGS:

USE COPPER WIRE,

CLASS 1 WIRE ONLY.

CAUTION

: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

/TSTAT

M4-LHS

HYBRID CONTROL

Wiring to Modulating Boilers

page 23. Some modulating boilers may require the use of the stage output relays in addition to the modulating output.

WarNiNg

The Modulating Output Type must be set to match the boiler modulating

signal prior to wiring the boiler signal to avoid control or equipment damage.

Wiring the 4-20ma Modulating Boilers

(A Terminals 13, 14), (B Terminals 16, 17),...

• The M4-LHS can operate up to four 4-20 mA modulating motors.

• The Extension can operate up to six 4-20 mA modulating motors.

• The M4-LHS and the Extension sources excitation voltage for the

4-20mA signal.

• Wire the (-) from the boiler modulating motor to the (GND) terminal

on the M4-LHS. That is for boiler A, the modulating (GND) terminal

will be 13.

• Wire the (+) from the boiler modulating motor to the (mA+) terminal

on the M4-LHS. That is for boiler A, the modulating (mA+) terminal

will be 14.

OD=

55

o

F SYS=

142

o

F

B

80%

50%

STAGE ◄ ► MENU

Modulating Boiler (Modulating

Boiler Type)

Boiler 4-20mA

Modulation Output

4-20mA

Burner

Motor

-

+

SYSTEM

A

B

C

D

1 2

RUN

PROGRAM

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

3 4 5 6 7 8 9 10 11 12

13

15

14

17

16

18

20

19

21

24

23

29

25

27

26

28

32

30 31

L N

-

+

+

T

T

O

O

RS-485

mA

GND

VLT

SYS

A

B

C

D

PWR

CUR / VLT

A

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

+

+

mA

22

-

GND

VLT

+

mA

TEMP

OUTDOOR

O

O

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

PROVE

/DHW

SHUTDOWN

/SETBACK

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 30VA MAX

INPUT RATINGS:

USE COPPER WIRE,

CLASS 1 WIRE ONLY.

CAUTION

: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

/TSTAT

M4-LHS

HYBRID CONTROL

Wiring Voltage Modulating Boilers

(A Terminals 13, 15), (B Terminals 16, 18),...

• The M4-LHS can operate up to four 0-10V modulating motors.

• The Extension can operate up to six 0-10V modulating motors.

• Wire the (GND) from the boiler modulating motor to the (GND) terminal on the M4-LHS. For boiler D, the

modulating (GND) terminal is be 22.

• Wire the (VLT+) from the boiler modulating motor to the (VLT+)terminal on the M4-LHS. For boiler D, the

modulating (VLT+) terminal is be 23.

Boiler Voltage

Modulation Output

Voltage

Burner

Motor

GND

V+

SYSTEM

A

B

C

D

1 2

RUN

PROGRAM

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

3 4 5 6 7 8 9 10 11 12

13

15

14

17

16

18

20

19

21

24

23

29

25

27

26

28

32

30 31

L N

-

+

+

T

T

O

O

RS-485

mA

GND

VLT

SYS

A

B

C

D

PWR

CUR / VLT

A

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

+

+

mA

22

-

GND

VLT

+

mA

TEMP

OUTDOOR

O

O

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

PROVE

/DHW

SHUTDOWN

/SETBACK

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 30VA MAX

INPUT RATINGS:

USE COPPER WIRE,

CLASS 1 WIRE ONLY.

CAUTION

: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

99RA

/TSTAT

M4-LHS

HYBRID CONTROL