Fan and shaft removal (fig. 44), Lubrication – Carrier 39LB User Manual

Page 38

38

10. Check fan shaft diameter at bearing mount. If worn by

more than .001 in. below nominal, shaft should be re-

placed.

11. Install new bearing, tighten holddown bolts and then

tighten bearing locking collar and setscrews.

12. Make certain fan wheel does not rub sides of fan housing

after installing new bearings.

13. Recoat fan shaft with a rust inhibitor or grease.

14. Replace sheave and belts. Adjust and align as described

in Installation sections on installing sheaves and V-belts.

15. Remove insulation protection.

16. Replace access panels.

17. Restore electrical power.

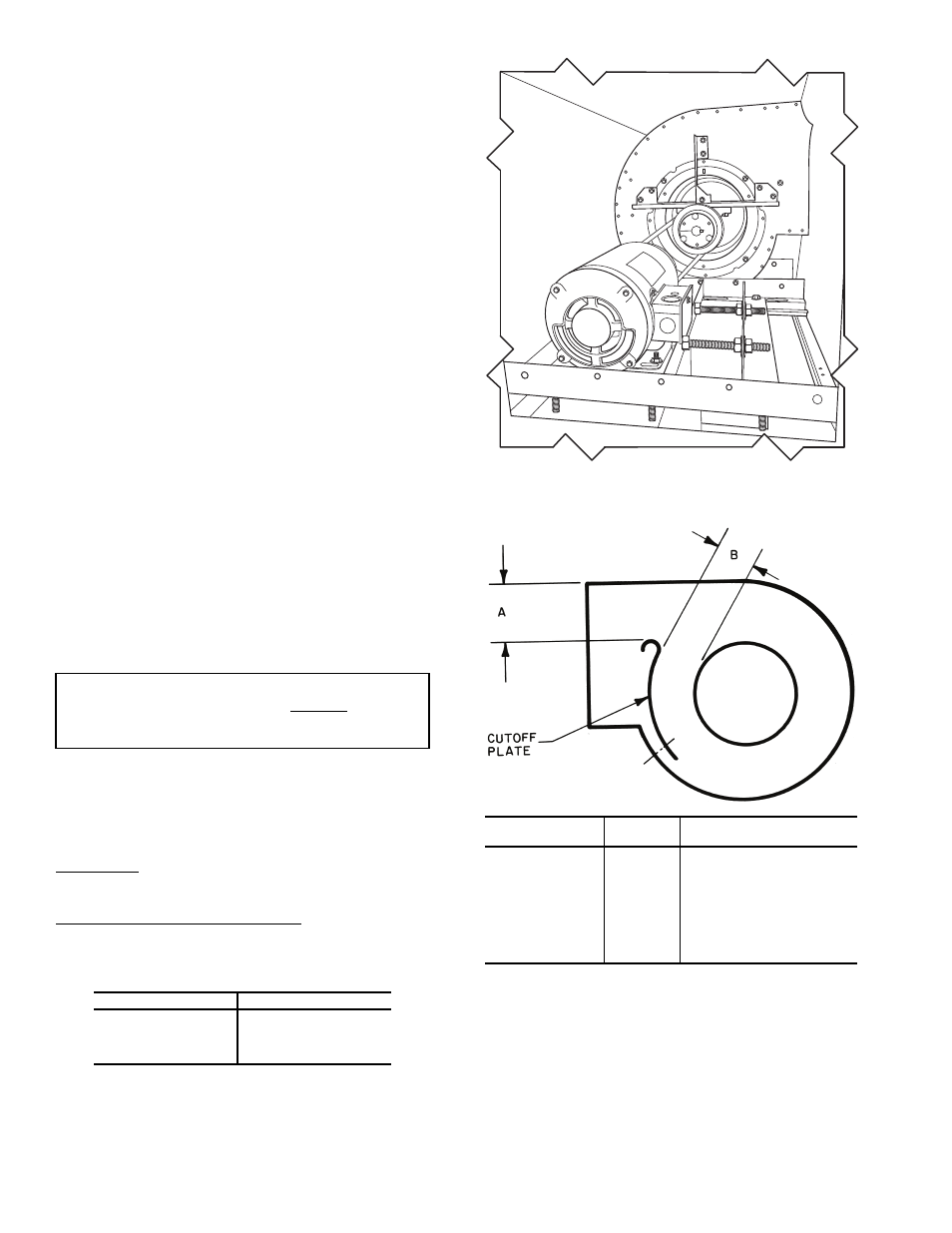

Fan and Shaft Removal (Fig. 44) —

The fan wheel

and shaft may be removed through inlet side of fan housing.

1. Remove drive belts as described in Fan Shaft Bearing Re-

moval on page 36.

2. Block up fan wheel within housing to prevent dropping

when bearing bolts are removed.

3. Loosen and remove bearing holddown bolts.

4. Remove bearing support channels and inlet ring from one

side.

5. Remove fan shaft and fan wheel from unit.

6. Remove fan shaft from fan wheel.

7. Replace shaft and wheel into fan in the reverse order of

their removal.

8. Inspect bearings and if serviceable, replace on shaft.

9. Align fan wheel and shaft assembly in fan scroll. Check

cutoff location if wheel failure damaged cutoff plate. See

Fig. 45.

10. Tighten bearing holddown bolts, bearing setscrews and

shaft setscrews.

11. Field balancing of shaft and wheel is recommended.

Lubrication

MOTORS — Lubricate in accordance with nameplate at-

tached to motor or with manufacturer’s recommendations

included with motor.

BEARINGS

Fan Bearings — Lubricate fan bearings every 3 months

with suitable bearing grease. Typical lubricants are given in

Table 13.

Inlet Vane and Outlet Damper Bearings — These bearings

are oil-impregnated. Annually lubricate with a few drops of

nondetergent SAE (Society of Automotive Engineers) 20 oil.

Table 13 — Lubricant Data

*Preferred lubricant because it contains rust and oxi-

dation inhibitors.

IMPORTANT: Replacement shafts must have a diam-

eter tolerance at bearing mount of

nominal.

Carrier-specified parts are recommended.

MANUFACTURER

LUBRICANT

Sunoco

Prestige 42

Texaco

Multipak 2

Texaco

Regal AFB-2*

Mobil

Mobilplex EP No. 1

+ .0000

– .001

Fig. 44 — Fan Shaft and Bearing Removal

(Unit without IGVs shown)

Fig. 45 — Fan Cutoff Plate Data (in.)

39L UNIT SIZE

CUTOFF

A

CUTOFF CLEARANCE

B

03

6

5

/

8

7

/

8

06

8

1

08

10

3

/

8

1

1

/

2

10

9

3

/

4

1

3

/

8

12

9

3

/

4

1

3

/

8

15

12

1

5

/

8

18

15

3

/

4

2

21

15

3

/

4

2

25

20

1

/

2

2

11

/

16