Carrier 39LB User Manual

Page 19

19

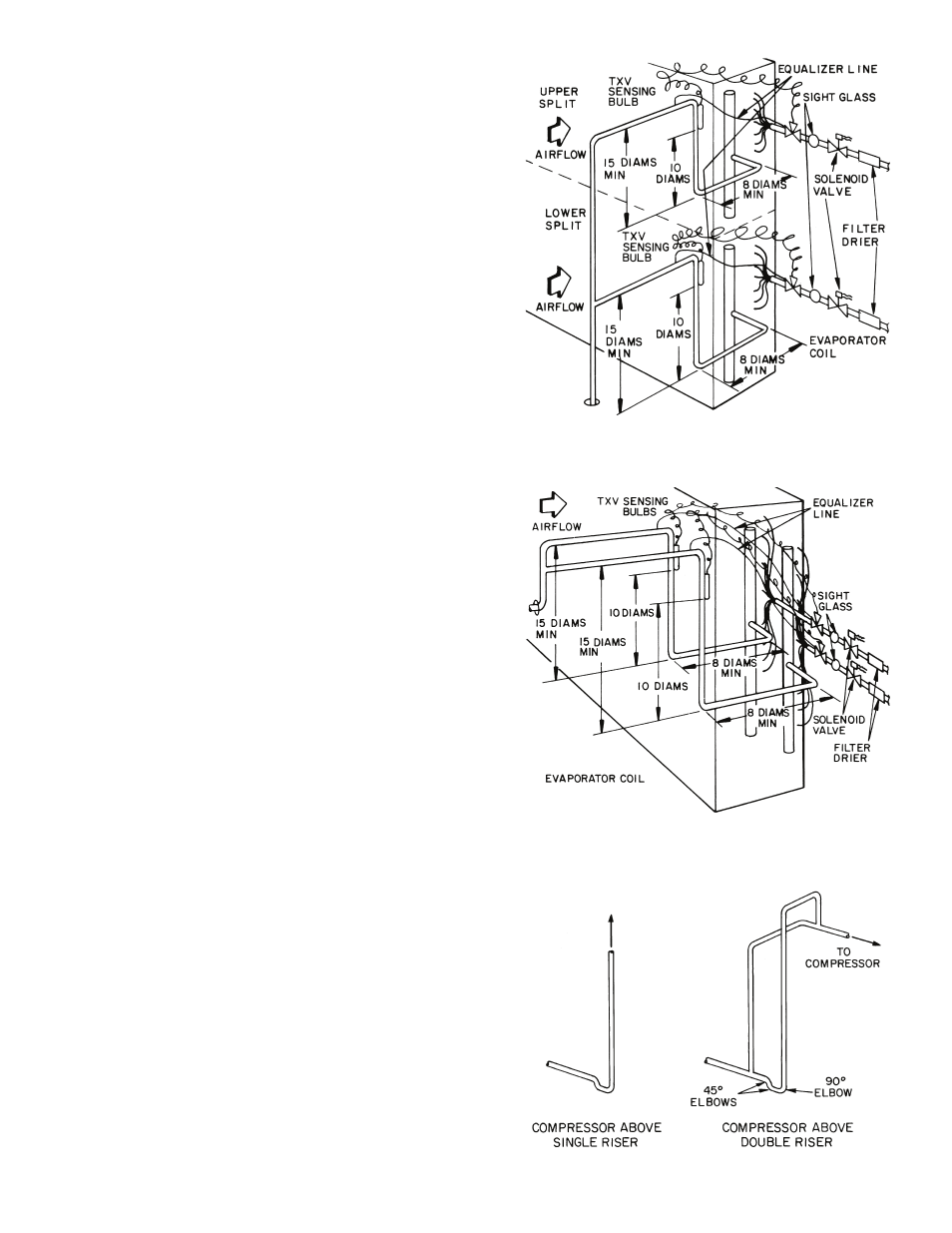

SUCTION PIPING — Connect suction piping as shown in

Fig. 24 for face split coil or Fig. 25 for row split coil.

Suction line from coil connection to end of the 15-diameter-

long riser should be same tube size as coil connection to ensure

proper refrigerant velocity.

Refer to Carrier System Design Manual, Part 3, and size re-

maining suction line to compressor for a pressure drop equiva-

lent to 2.0 F. This will provide a total suction line header pres-

sure drop equivalent to approximately 2.5 F. Refer to Fig. 26

for piping risers to the compressor.

To minimize the possibility of flooded starts and compres-

sor damage during prolonged light load operation, install an ac-

cumulator in the suction line or a solenoid in the liquid line of

last-on, first off split in row-split applications.

EXPANSION VALVE PIPING — Distributor nozzles sized

for acceptable performance for a range of conditions are facto-

ry supplied. Use the AHU (Air-Handling Unit) selection pro-

gram in the Carrier electronic catalog to select optimal nozzle

sizes. Replace factory nozzle as necessary for best perfor-

mance. See Fig. 27.

Thermostatic expansion valves are field supplied. See

Fig. 27.

NOTE: Be sure that correct nozzle is installed in each distribu-

tor before installing expansion valve. Before installing field-

supplied nozzles, remove nozzle retainer rings and factory-

installed minimum-sized nozzles from distributors.

Install expansion valve (Fig. 27) as follows:

1. Wrap wet cloths around valve body to prevent excessive

heat from reaching diaphragm and internal parts. Do not

allow water to enter system. Disassemble expansion

valve before soldering, if accessible, for easy reassembly.

Use 95-5 tin-antimony soft solder.

2. Solder expansion valve outlet directly to distributor un-

less:

a. An adapter bushing or coupling is supplied by the

factory (solder adapter to distributor first, then to

expansion valve).

b. Hot gas bypass is required. (See Hot Gas Bypass

section, below.)

3. Solder expansion valve equalizer line to suction line and

locate control bulb on suction line as in Fig. 24 or 25.

4. Insulate expansion valve body, diaphragm assembly and

control bulb area to prevent charge migration and exces-

sive condensation.

5. Install filter drier ahead of expansion valve to ensure sat-

isfactory valve operation.

HOT GAS BYPASS — When low-load operation requires

use of hot gas bypass, hot gas must be introduced between ex-

pansion valve and distributor. See Table 9.

Install hot gas bypass connector (Fig. 28) in coil split that is

first on, last off as follows:

1. Remove distributor nozzle and retainer ring (area A) from

distributor and reinstall in inlet (area B) of side connector.

2. Solder side connector outlet to distributor inlet, using

silver solder or equivalent with 1300 to 1500 F melt

temperature.

3. Silver-solder expansion valve outlet to side connector

inlet.

4. If required, install factory-supplied adapter bushing or

coupling to connector inlet before soldering to expansion

valve outlet.

TXV — Thermostatic Expansion Valve

Fig. 24 — Face Split Coil Suction Line Piping

TXV — Thermostatic Expansion Valve

Fig. 25 — Row Split Coil Suction Line Piping

Fig. 26 — Suction Line Riser Piping