Carrier 39LB User Manual

Page 35

35

Changing Coil Hand

NOTE: Electric heat coil hand cannot be changed.

NOTE: The coil cover panel is not part of the coil. Remove

cover panel from end of unit. New holes must be cut in coil

cover panel. Original holes must be plugged and insulated.

New side panels may be necessary when changing coil hand.

NU-FIN COILS — The NuFin coil is airflow direction sensi-

tive, especially when used in dehumidifying applications.

Hydronic versions are counterflow circuited for full gravity

draining when installed level.

Correct installation will result in the typical bottom inlet on

leaving air face and top outlet on entering air face of coil, a

self-venting design. This will ensure cold air contact with cold

water, and warm air with hot water.

Coil repositioning for opposite hand application will com-

promise one or more of these characteristics. However, there

will be those situations where this may prove acceptable.

As a general rule, a change from counterflow circuiting to

parallel flow for sensible heating and cooling applications will

result in a 5% drop in net capacity per row of coil. In one and

two row heating coils, the actual drop may not be measurable,

thus of insignificant consequence.

It is important that the airflow direction of the NuFin coil be

adhered to when latent cooling is possible. Significant moisture

carryover from the face of the dehumidifying coil will result if

this rule is violated, even at very low face velocities. The same

result is often experienced if after-market fin coatings are

applied.

If a NuFin hydronic coil is installed with correct airflow, but

opposite piping hand, and counterflow is maintained, steps

must be taken to ensure that the coil is continuously vented,

and that the water velocity is maintained to prevent the coil

from air-binding.

Hot or cold areas of the coil face (or otherwise broad tem-

perature differences and stratification) are usually indications

that one or more circuits are air-locked internally. This can

result in coil freeze-up (a condition NOT covered by warranty).

Refrigerant coils may be rotated for opposite hand applica-

tions, maintaining the proper airflow direction.

Do not reposition the distributor(s), they will perform equal-

ly well in upflow or downflow positions. When soldering

expansion valves to up-feed distributors, use the minimum

satisfactory amount of solder to prevent damaging the valve or

plugging passages.

DIRECT EXPANSION COILS — Rotate the coil in vertical

plane and reinstall. Distributor must be on downstream side of

coil. (Refer to Fig. 42).

CHILLED WATER AND HOT WATER COILS — These coils

can be rotated. If coil is rotated in vertical plane and reinstalled

with counterflow maintained, supply will be at the top of the coil

and return will be at the bottom. Ensure coil is continuously

vented and water velocity is maintained to prevent air binding.

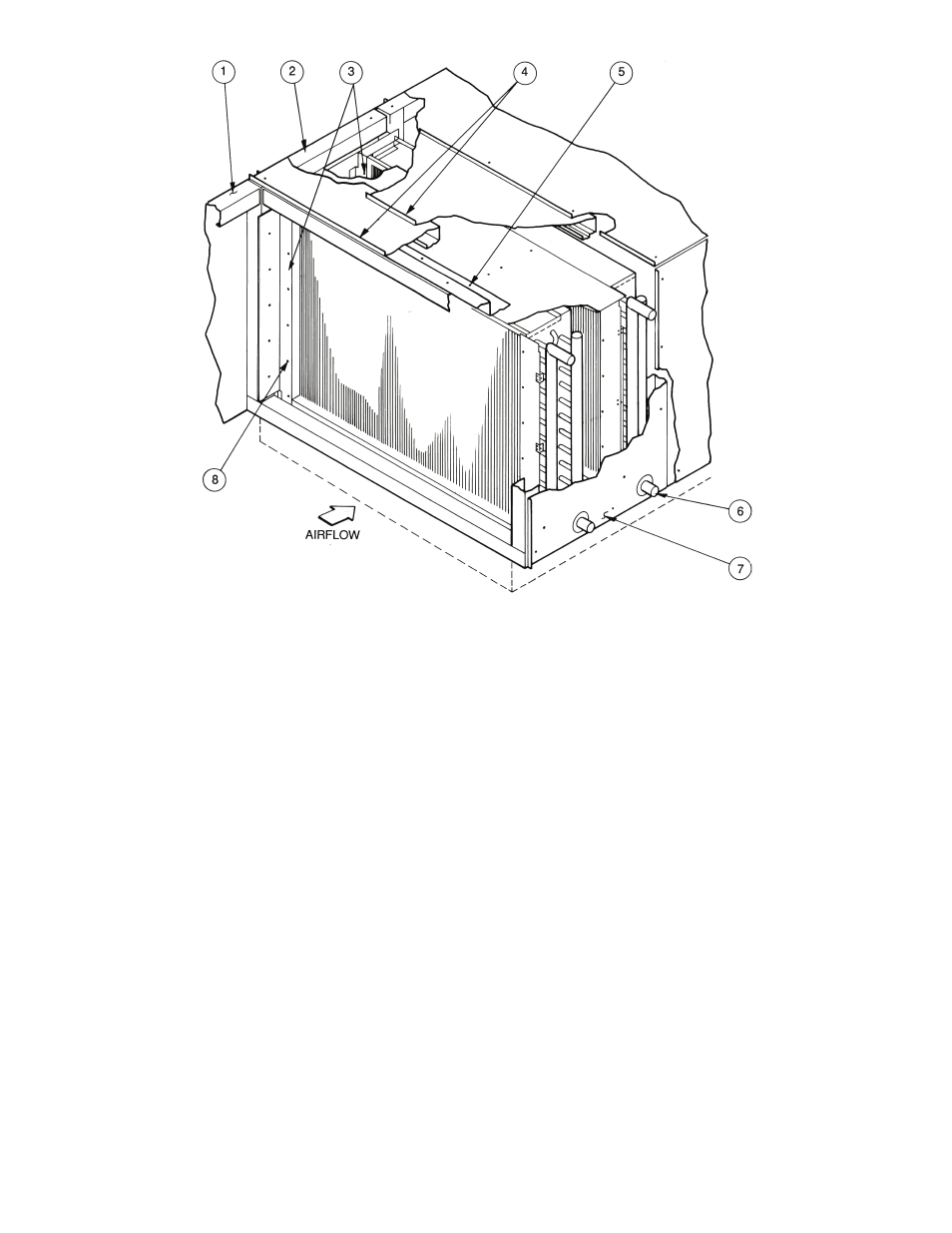

LEGEND

Fig. 41 — Horizontal or Vertical Unit — Vertical Coil Removal (39LB,LC,LF,LH Units)

1 —

Accessory Side Panel

5

— Baffle Angle Screw

2 —

Left Side Panel

6

— Piping

3 —

Inside Baffles

7

— Right Side Panel

4 —

Top Panels

8

— Baffle Screw