Heckler&Koch MR762A1-LRP User Manual

Page 8

14

15

SECTION 4 — SIGHTS, SIGHT ADjUSTMENT, AND AIMING

MR762A1 rifles can accommodate a wide variety of optical and mechanical (iron) sights.

For models with HK Diopter rotary sight sets, the sights are installed on the MIL-STD-

1913 (Picatinny) rail with a Phillips #2 screwdriver or the HK sight tool (Fig. 5 & 6). Do not

over tighten the screws.

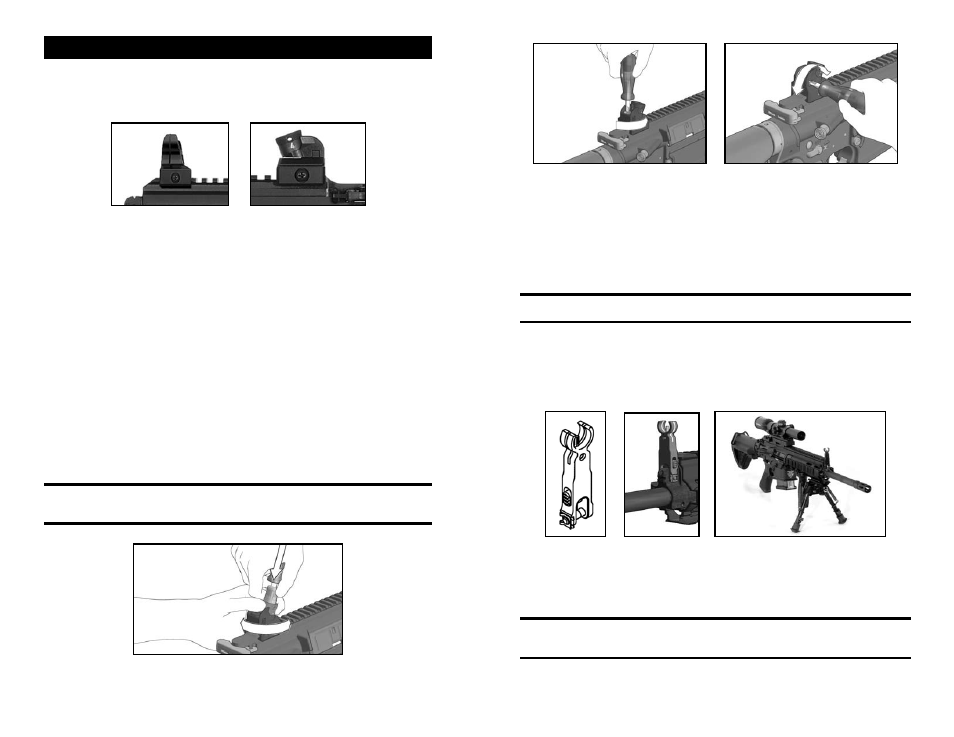

Fig. 5 – Front Diopter Sight Fig. 6 – Rear Diopter Sight

For optimal sight use and the longest sight radius, the front sight is installed on the

most forward portion of the MIL-STD-1913 rail and the rear sight is installed on the

most rearward portion of the MIL-STD-1913 rail (located on the upper receiver). Sight

adjustment is as follows:

1. Place target 100 meters (109.3 yards) downrange

2. Rotate rear drum until the 100 meter setting (“1”) is visible to the shooter

3. Utilizing the HK sight adjustment tool and the acronym LLC (Low Left Clockwise);

adjust the strike of the round until point of aim (POA) equals point of impact (POI).

Any corrections which may be required when sighting-in the weapon may only be

performed by adjusting the rear sight for elevation or windage. MR rifles are designed to

be sighted in at a range of 100 meters.

ELEvATION ADjUSTMENT

Insert elevation adjustment tool into the rear sight cylinder so that the wedges of the

tool engage in the two slots in the cylinder which contain the catch bolts. Press Phillips-

head screwdriver downward into the adjustment tool and hold firmly. Rotate rear sight

cylinder manually in the desired direction (Fig. 7). After correction withdraw Phillips-head

screwdriver and remove elevation adjustment tool. The catch bolts will then re-engage in

the slots. After performing the elevation adjustment set the desired aperture again.

NOTE: Elevation: One 1/4 click of the drum will move the strike of the road

approximately 1.5” (3.8cm) @ 100 meters. One 360 degree rotation of the drum will

move the strike of the road approximately 6” (15.2cm) @ 100 meters.

Fig. 7 – Rear Sight Adjustment

Fig. 8 – Clamping Screw Fig. 9 – Windage Adjustment

(to tighten turn clockwise)

WINDAGE ADjUSTMENT

Point of impact, left: Loosen clamping screw on top of sight base (Fig. 8). Turn adjusting

screw on the right side counterclockwise (Fig. 9) in accordance with the required

correction. Then retighten clamping screw. This will move the impact to the Right.

Point of impact, right: Loosen clamping screw (Fig. 8). Turn adjusting screw clockwise

(Fig. 9) until the required correction has been performed. Then retighten clamping screw.

This will move the impact to the Left.

NOTE: Windage: One 360 degree rotation of the windage screw will move the strike

of the road approximately 6” (15.2cm) @ 100 meters.

INSTALLING THE OPTIONAL FLIP-UP FRONT SIGHT

Press front sight onto front sight holder until the axes holes of front sight and front sight

holder are aligned. Push through front sight axles all the way, from the right to the left

and secure the front sight axles by snapping the retaining clip. Check function of foldable

front sight (Fig. 10 & 11).

Fig. 10 Fig. 11 Fig. 12

A wide variety of mechanical, optical, telescopic sights and accessories can be installed

directly on the upper MIL-STD-1913 rail (example, Fig. 12), either on the upper receiver

portion of the rail or on the four quadrants of the Free Floating Rail System. For sight

alignment and zeroing, follow the instructions of the scope manufacturers (Fig. 12).

NOTE: Do not overtighten scopes, aimers, or any other accessories mounted on any

of the MIL-STD-1913 (Picatinny) rail surfaces of the MR762A1. Overtightening can

damage the rails.