Great Planes Venus II 60 ARF - GPMA1027 User Manual

Page 10

❏

4. Connect a 12" [300 mm] servo extension wire to each

aileron servo. Cut one of the included black heat shrink

tubes in half, making two 1-1/2" [40 mm] pieces. Center the

pieces of tubing over the connections between the servo

wires and the extensions and use a heat gun to shrink the

tubing, making the connections secure.

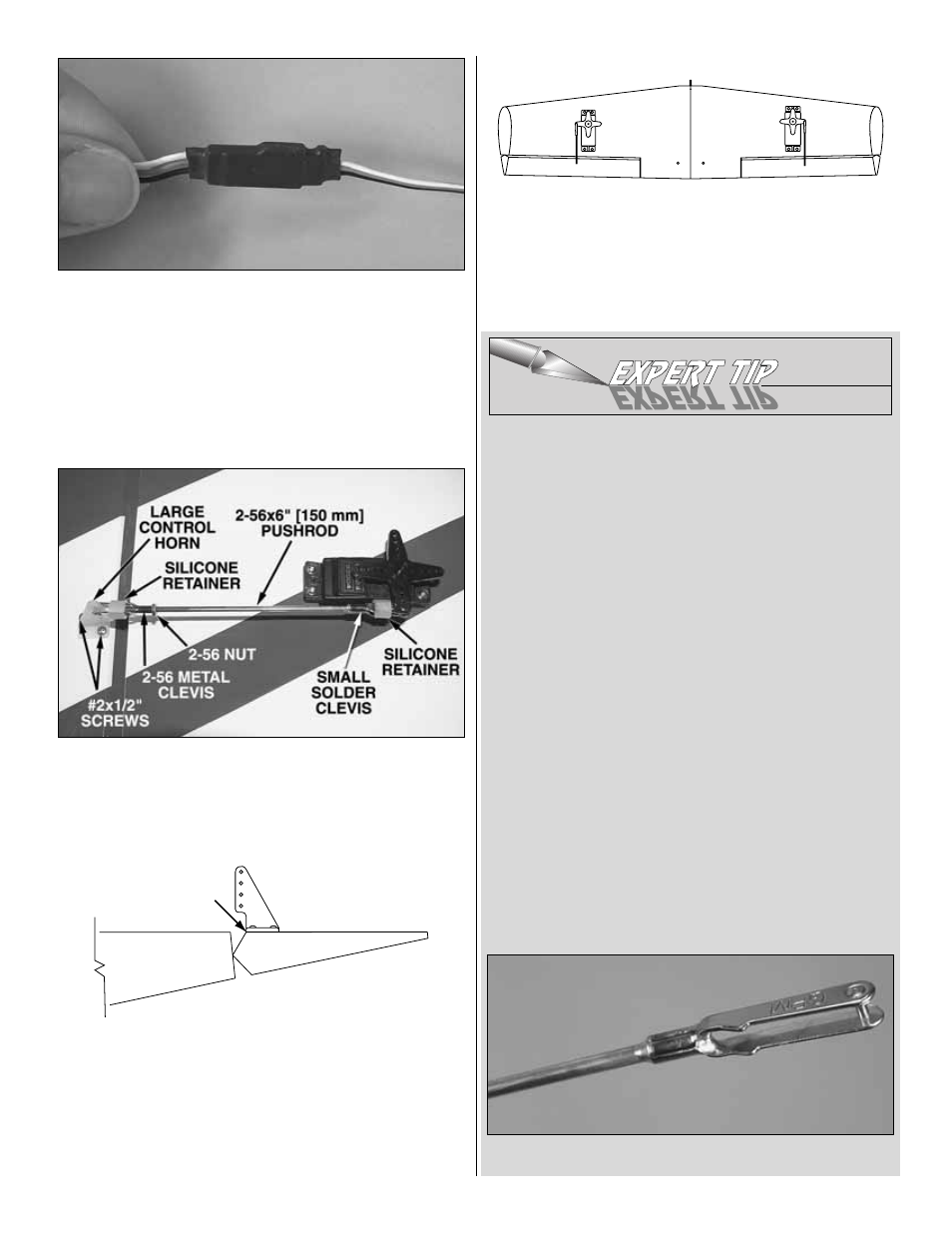

Refer to this photo while mounting the servos

and hooking up the ailerons.

❏

5. Use the string in the wings to pull the servo wires out

while placing the servos in the openings. With the servos in

position, drill 1/16" [1.6 mm] holes into the wing for all the

servo mounting screws. Temporarily mount the servos with

the servo mounting screws that came with your servos.

❏

6. Read the Expert Tip below on how to solder. Then

connect the aileron servos to the ailerons using the

hardware shown in the photo. When mounting the horns,

place the front edge at the front edge of the aileron as

indicated by the arrow in the illustration. Drill 1/16" [1.6 mm]

holes through the ailerons for the screws. If using new, four-

arm servo arms, do not cut the extra arms off until instructed

to do so when setting up the radio later.

Note: Set up the ailerons so the servo arms that the

pushrods will be mounted to are opposed.

HOW TO SOLDER

❏

A. Use denatured alcohol or other solvent to thoroughly

clean the pushrod. Roughen the end of the pushrod with

coarse sandpaper where it is to be soldered.

❏

B. Apply a few drops of soldering flux to the end of the

pushrod, and then use a soldering iron or a torch to heat it.

“Tin” the heated area with silver solder (GPMR8070) by

applying the solder to the end. The heat of the pushrod

should melt the solder—not the flame of the torch or

soldering iron—thus allowing the solder to flow. The end of

the wire should be coated with solder all the way around.

❏

C. Place the clevis on the end of the pushrod. Add

another drop of flux, then heat and add solder. The same as

before, the heat of the parts being soldered should melt the

solder, thus allowing it to flow. Allow the joint to naturally cool

without disturbing. Avoid excess blobs, but make certain the

joint is thoroughly soldered. The solder should be shiny, not

rough. If necessary, reheat the joint and allow to cool.

❏

D. Immediately after the solder has solidified, but while it

is still hot, use a cloth to quickly wipe off the flux before it

hardens. Important: After the joint cools, coat with oil to

prevent rust. Note: Do not use the acid flux that comes with

silver solder for electrical soldering.

This is what a properly soldered clevis looks like—shiny

solder with good flow, no blobs, flux removed.

CONNECT THE PU

S

HROD

S

TO THE

S

ERVO

ARM

S

S

O THEY ARE OPPO

S

ITE, A

S

S

HOWN.

10