Install the motor system – Great Planes RC Universe FlatOuts ARF - GPMA1117 User Manual

Page 16

❏

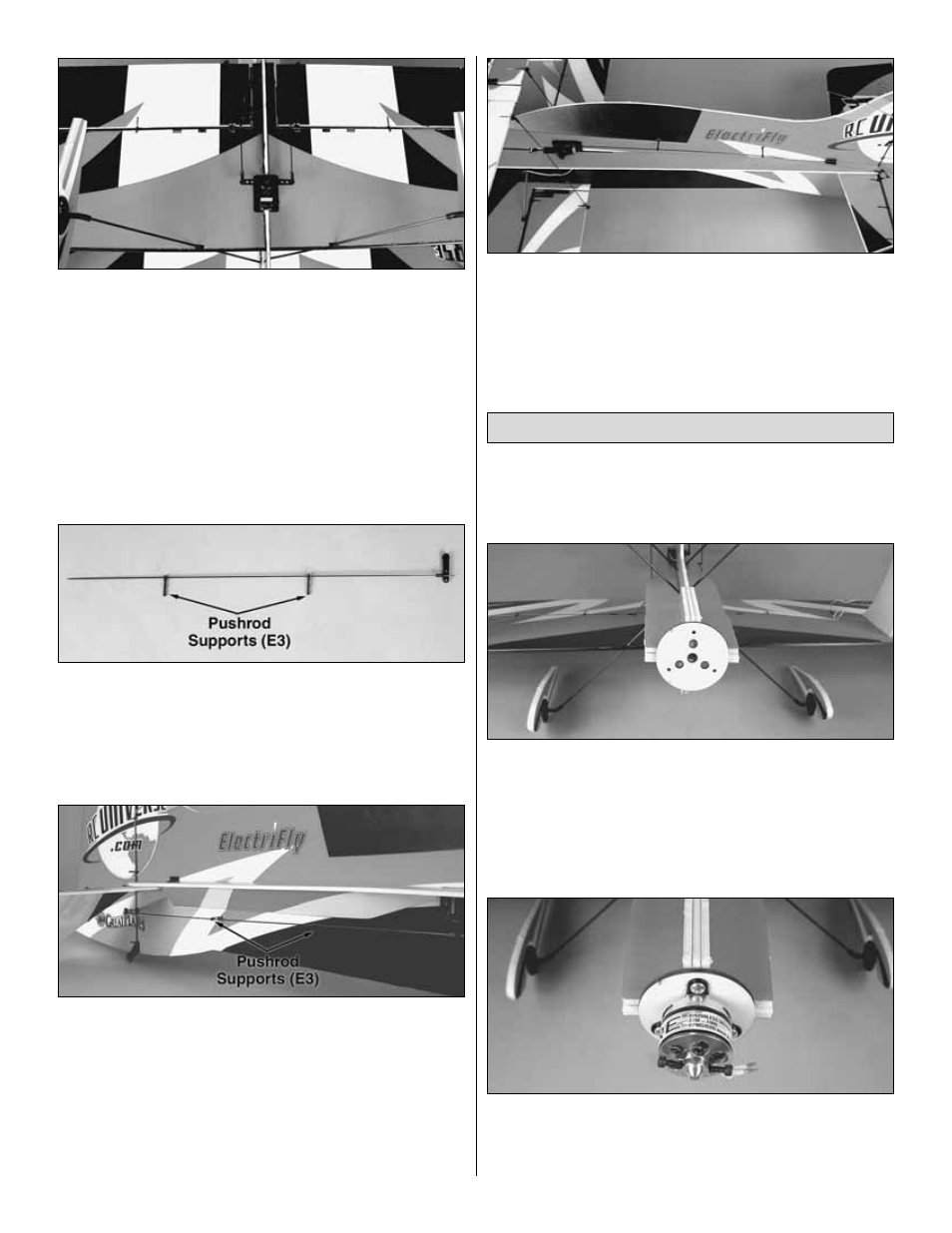

8. Insert two Z-bend clevises (A1) into the outer holes of a

double-sided servo arm that fits your servo and two Z-bend

clevises into the aileron control horns. Push the 1 x 80 mm [1/32"

x 3-1/8"] aileron pushrods into the clevises on the control

horns. Now attach the clevises in the servo arm onto the other

ends of the pushrods. Screw the arm onto the aileron servo and

adjust the depth of the pushrods in the clevises so that the

ailerons are in the neutral position when the servo arm is parallel

to the wing leading edge. When satisfied with their fit, a few

drops of glue on the pushrods will secure them in place.

❏

9. Fit a Z-bend clevis into the middle hole of a single-

sided servo arm that fits your servo. Slide the 1 x 340 mm

[1/32" x 13-1/2"] rudder pushrod into the clevis in the servo

arm and slide two pushrod supports (E3) onto the other

end of the rod.

❏

10. Attach the other end of the rudder pushrod to the

clevis in the control horn and secure the arm to the servo.

Adjust the pushrod as you did with the ailerons so that the

rudder is neutral with the servo arm pointing straight down.

Glue the pushrod to the clevises and attach the supports to

the fuselage an equal distance apart (pre-drilling a hole for

the supports with a 2.4 mm [3/32"] bit is recommended). Do

not push the supports all the way through the fuselage. Glue

the supports in place.

❏

11. Repeat the same procedure with the elevator servo

using the 1 x 370 mm [1/32" x 14-5/8"] elevator pushrod.

Connect the clevis to the outer hole on the servo arm.

❏

1. If necessary, use a bar sander with 220-grit sandpaper

to lightly sand the front of the fuselage even. Be careful not

to change the built-in thrust angles.

❏

2. If installing an ElectriFly RimFire

™

motor, glue the

included 3 mm [1/8"] plywood firewall to the nose so that the

center hole is centered on the fuselage tube. Note: If

installing another brand of outrunner motor, you will need to

cut your own or modify the included firewall to match its

mount pattern. The motor and firewall should be mounted so

that the thrust line is centered on the fuselage tube.

❏

3. Mount the motor using the hardware and instructions that

came with your motor. Back the mounting screws out and use

thin foam-safe CA glue to reinforce the holes in the firewall.

Allow the glue to dry completely before reattaching motor.

Install the Motor System

16