Digital corner correction – Flintec II IPC User Manual

Page 24

FlintWeigh II IPC Technical Manual, Rev. 1.06 November 2011

Page 24 of 36

Scale type:

Setting

Comment

Single-interval

The scale has exactly one weighing range with a constant

scale interval

Multi-range

The scale has 2 or 3 weighing ranges with different scale

intervals. If the current gros value of the measured weight falls

within the next weighing range and larger scale interval

(changeover threshold 1 and 2), then the larger scale interval

remains active until the scale will be unloaded and will return to

the zero point.

Multi-interval

The scale has 2 or 3 weighing ranges with different scale

intervals. The current value of the measured weight determines

the active weighing range and the active scale interval at any

time.

Scale interval 1/2/3: Step size of the display resolution for the scale respective the weighing range

Decimals:

Number of digits after the decimal point

Unit:

Weight unit for the displayed weight: g, kg, t or lb

No-motion range /

period:

Condition for a stable scale (no. of scale intervals, no. of measured values);

Default: 2d and 10 values in legal for trade applications; in industrial applications these

criteria may be modified

Max. capacity:

Maximum load of the scale (as a multiple of the scale interval e1)

Min. capacity:

Minimum load of the scale (as a multiple of the scale interval e1)

Test weight:

Weight of the calibration weight (as a multiple of the scale interval e1)

Changeover

threshold 1/2:

Only for multi-range / multi-interval scales:

Transition points for range or interval (as a multiple of the scale interval e1)

Important: For saving all scale parameter settings you have to close the window FlintWeigh II Settings

afterwards.

Now the weight display (Fig. 7.1) should show a random value.

The next step is the digital corner correction (see chapter 8.4.3).

8.4.3.

Digital Corner Correction

Important: After the digital corner correction the scale always requires a new calibration.

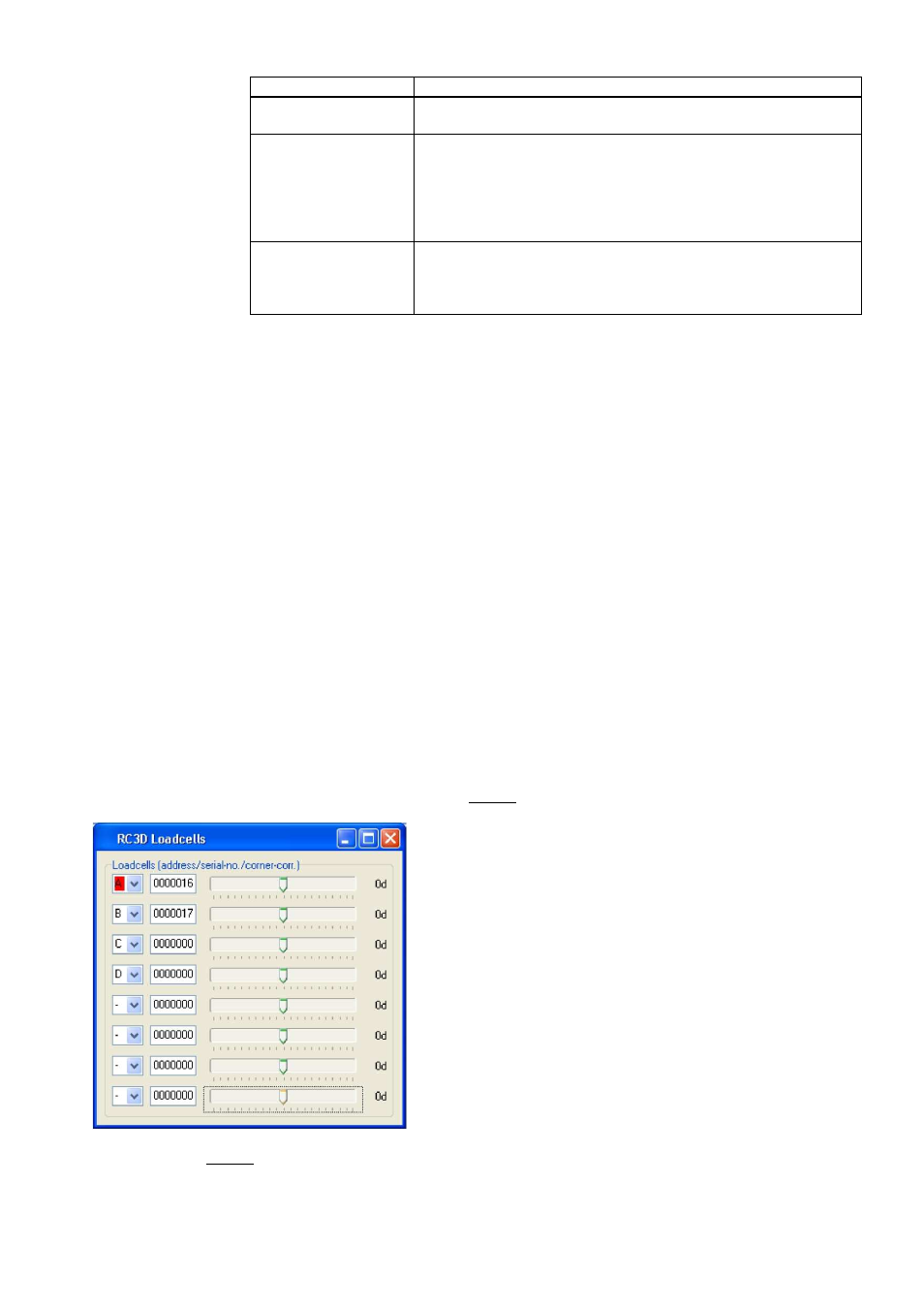

Fig.8.11 RC3D Load cells

Each corner (load cell) will be loaded one after the other with a

calibration weight (the calibration weight should be at least 10%

of max. capacity; better is 30% of max.capacity).

Using the slider the display value of the loaded load cell will be

corrected until the displayed value equals the calibration

weight.

The corner correction doesn’t depend on the sequence of the

loaded load cell, but a systematic course may spare time and

minimises the risk for errors (see chapter 8.4.1).

Hint: It may be meaningful to perform a calibration of the scale

and save the calibration data before the corner correction. This

optimises the display characteristics already before the corner

correction.

The next step is always the calibration of the scale (see chapter 8.5)