EVCO EPK4BHQ1AH User Manual

C-pro 3 node kilo+ - programmable controllers

4.2

Meaning of connectors

The following charts show the meaning of the connectors of

the devices.

For further information look at chapter “TECHNICAL DATA”.

POWER

Power supply device (24 VAC/DC not isolated).

If the device is powered in direct current, it will be necessary

to respect the polarity of the power supply voltage.

If the device is connected to a devices network, it will be

necessary:

-

the power supply of the devices making the network is

galvanically isolated one another

-

the phase supplying the device is the same supplying all

the devices making the network.

Part Meaning

AC/+ power supply device:

-

if the device is powered in alternate current,

connect the phase

-

if the device is powered in direct current, con-

nect the positive pole

AC/-

power supply device:

-

if the device is powered in alternate current,

connect the neutral

-

if the device is powered in direct current, con-

nect the negative pole

ANALOG INPUTS

Analog inputs.

Part Meaning

GND

ground analog inputs

AI1

analog input 1, which can be set via configuration

parameter for PTC, NTC, Pt 1000 probes, 0-20 mA,

4-20 mA, 0-5 V ratiometric or 0-10 V transducers

AI2

analog input 2, which can be set via configuration

parameter for PTC, NTC, Pt 1000 probes, 0-20 mA,

4-20 mA, 0-5 V ratiometric or 0-10 V transducers

AI3

analog input 3, which can be set via configuration

parameter for PTC, NTC, Pt 1000 probes, 0-20 mA,

4-20 mA, 0-5 V ratiometric or 0-10 V transducers

AI4

analog input 4, which can be set via configuration

parameter for PTC, NTC or Pt 1000 probes

AI5

analog input 5, which can be set via configuration

parameter for PTC, NTC or Pt 1000 probes

AI6

analog input 6, which can be set via configuration

parameter for PTC, NTC or Pt 1000 probes

GND

ground analog inputs

+5V

power supply 0-5 V ratiometric transducers (5 VDC)

EVCO S.p.A. | Code 104CP3NKPE103 | Page 1 of 2 | PT 46/14

c-pro 3 NODE kilo+ - Programmable controllers

GB

ENGLISH

IMPORTANT

Read this document carefully before installing and using the device and follow all the additional information; keep this

document close to the device for future consultations.

For further information consult the hardware manual.

The device must be disposed according to the local legislation about the collection for electrical and electronic

equipment.

1

INTRODUCTION

1.1

Introduction

c-pro 3 NODE kilo+ is a range of programmable controllers for applications in refrigeration and air conditioning sectors.

The controllers have a considerable number of inputs and outputs; they allow to realize a flexible, modular and expandable

control devices network.

The variety of available communication ports (RS-485, CAN, USB and Ethernet) and supported communication protocols

make easier the integration of the devices in systems.

The application software can be realized through the UNI-PRO 3 development environment for programmable controllers.

4

ELECTRICAL CONNECTION

4.1

Connectors

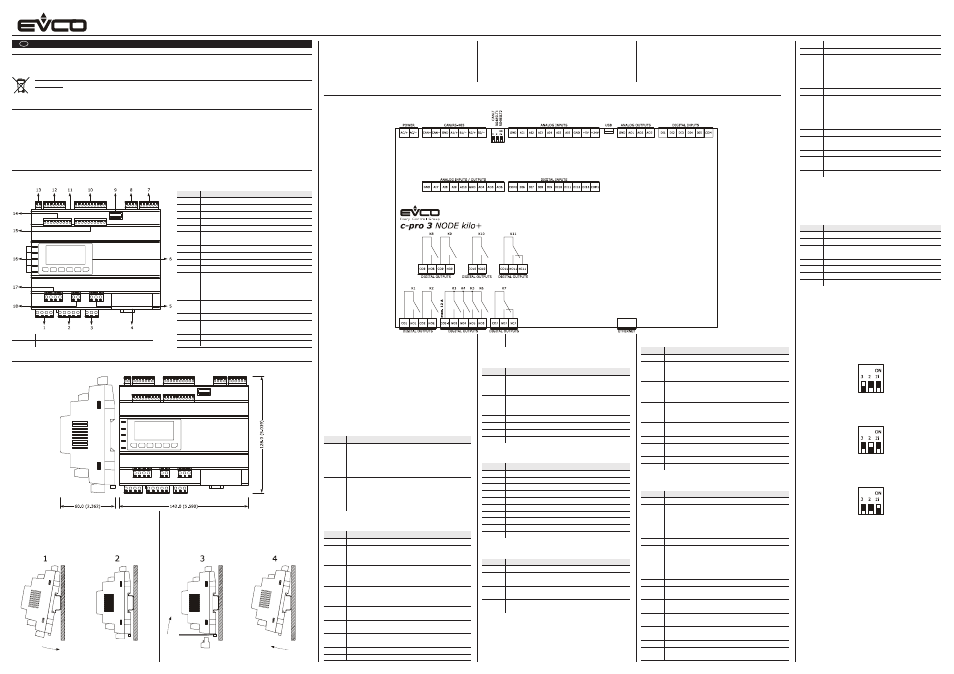

The following drawing shows the connectors of the devices.

The following chart shows the meaning of the parts of

the devices.

Part Meaning

1

digital outputs K1 and K2

2

digital outputs K3, K4, K5 and K6

3

digital output K7

4

MODBUS TCP, Web Server Ethernet port

5

digital output K11

6

display and keyboard (not available in the blind

versions)

7

digital inputs 1... 5

8

analog outputs 1... 3

9

USB port

10

analog inputs 1... 6

11

micro-switch to plug in the CANBUS CAN port

line termination, the MODBUS master/slave

RS-485 port line termination and the MODBUS

slave RS-485 port line termination

12

MODBUS slave RS-485 port, MODBUS master/

slave RS-485 port and CANBUS CAN port

13

power supply

14

analog outputs 7... 10 and analog outputs

4... 6

15

digital inputs 6... 13

16

signalling LEDs

NC7

normally closed contact digital output 7

CO8

common digital output 8

NO8

normally open contact digital output 8

according to the model:

-

3 res. A @ 250 VAC electromechanical relay

-

24 VAC/DC, 600 mA max. command for solid

state relay

CO9

common digital output 9

NO9

normally open contact digital output 9

according to the model:

-

3 res. A @ 250 VAC electromechanical relay

-

24 VAC/DC, 600 mA max. command for solid

state relay

CO10 common digital outputs 10

NO10 normally open contact digital output 10 (3 res. A

@ 250 VAC electromechanical relay)

CO11 common digital output 11

NO11 normally open contact digital output 11 (3 res. A

@ 250 VAC electromechanical relay)

NC11 normally closed contact digital output 11

CAN/RS-485

MODBUS slave RS-485 port, MODBUS master/slave RS-

485 port and CAN CANBUS port.

The communication protocol of the MODBUS master/slave

RS-485 port can be set with the development environment

UNI-PRO 3.

Part Meaning

CAN+ positive pole CANBUS CAN port

CAN- negative pole CANBUS CAN port

GND

ground MODBUS slave RS-485 port, MODBUS

master/slave RS-485 port and CAN CANBUS port

A1/+ positive pole MODBUS master/slave RS-485 port

B1/-

negative pole MODBUS master/slave RS-485 port

A2/+ positive pole MODBUS slave RS-485 port

B2/-

negative pole MODBUS slave RS-485 port

USB

USB port.

ETHERNET

MODBUS TCP, Web Server Ethernet port.

4.2

Plugging in the CANBUS CAN port line termi-

nation

To plug in the CANBUS CAN port line termination, position

micro-switch 3 on position ON.

4.3

Plugging in the MODBUS master/slave RS-

485 port line termination

To plug in the MODBUS master/slave RS-485 port line ter-

mination, position micro-switch 2 on position ON.

4.4

Plugging in the MODBUS slave RS-485 port

line termination

To plug in the MODBUS slave RS-485 port line termination,

position micro-switch 1 on position ON.

4.5

Polarizing the MODBUS master/slave RS-485

port

The polarization of the MODBUS master/slave RS-485 port

can be set via configuration parameter.

4.6

Polarizing the MODBUS slave RS-485 port

The devices are not able to polarize the MODBUS slave

RS-485 port; the polarization must be done by another

device.

4.7

Additional information for electrical connec-

tion

-

do not operate on the terminal blocks of the device

using electrical or pneumatic screwers

-

if the device has been moved from a cold location to a

warm one, the humidity could condense on the in-

side; wait about an hour before supplying it

-

make sure the power supply voltage, the electrical

frequency and the electrical power of the device cor-

respond to those of the local power supply; look at

chapter “TECHNICAL DATA”

-

disconnect the power supply of the device before serv-

icing it

3

SIZE AND INSTALLATION

3.1

Size

The following drawing shows the size of the devices (8 DIN modules); size is in mm (in).

2

DESCRIPTION

3.2

Installation

Installation is on DIN rail 35.0 x 7.5 mm (1.377 x 0.295

in) or 35.0 x 15.0 mm (1.377 x 0.590 in), into a switch-

board.

To install the devices operate as shown in the following

drawing.

To remove the devices remove possible extractable screw ter-

minal blocks plugged at the bottom first, then operate on the

DIN rail clips with a screwdriver as shown in the following

drawing.

To install the devices again press the DIN rail clips to the end

first.

3.3

Additional information for the installation

-

make sure the working conditions of the device (operat-

ing temperature, operating humidity, etc.) are in the limits

indicated; look at chapter “TECHNICAL DATA”

-

do not install the device close to heating sources (heat-

ers, hot air ducts, etc.), devices having big magnetos

(big speakers, etc.), locations subject to direct sunlight,

rain, humidity, dust, mechanical vibrations or bumps

-

according to the safety legislation, the protection against

possible contacts with the electrical parts must be en-

sured by a correct installation of the device; all the parts

which ensure the protection must be fixed so that you

can not remove them if not by using a tool.

+24V power supply 0-20 mA, 4-20 mA and 0-10 V trans-

ducers (24 VAC)

DIGITAL INPUTS

Digital inputs.

Part Meaning

DI1

digital input 1 (24 VAC/DC, 50/60 Hz or 2 KHz

optoisolated); the frequency can be set with the

development environment UNI-PRO 3

DI2

digital input 2 (24 VAC/DC, 50/60 Hz or 2 KHz

optoisolated); the frequency can be set with the

development environment UNI-PRO 3

DI3

digital input 3 (24 VAC/DC, 50/60 Hz optoisolated)

DI4

digital input 4 (24 VAC/DC, 50/60 Hz optoisolated)

DI5

digital input 5 (24 VAC/DC, 50/60 Hz optoisolated)

COM

common digital inputs

DIGITAL INPUTS

Digital inputs.

Part Meaning

COM1 common digital inputs

DI6

digital input 6 (24 VAC/DC, 50/60 Hz optoisolated)

DI7

digital input 7 (24 VAC/DC, 50/60 Hz optoisolated)

DI8

digital input 8 (24 VAC/DC, 50/60 Hz optoisolated)

DI9

digital input 9 (24 VAC/DC, 50/60 Hz optoisolated)

DI10 digital input 10 (24 VAC/DC, 50/60 Hz optoisolated)

DI11 digital input 11 (24 VAC/DC, 50/60 Hz optoisolated)

DI12 digital input 12 (24 VAC/DC, 50/60 Hz optoisolated)

DI13 digital input 13 (24 VAC/DC, 50/60 Hz optoisolated)

COM

common digital inputs

ANALOG OUTPUTS

Analog outputs.

Part Meaning

GND

ground analog outputs

AO1

analog output 1, which can be set via configuration

parameter for PWM or 0-10 V

AO2

analog output 2, which can be set via configuration

parameter for PWM or 0-10 V

AO3

analog output 3, which can be set via configuration

parameter for 0-20 mA, 4-20 mA or 0-10 V

ANALOG INPUTS / OUTPUTS

Analog inputs and outputs.

Part Meaning

GND

ground analog inputs and outputs

AI7

analog input 7, which can be set via configuration

parameter for PTC, NTC, Pt 1000 probes, 0-20 mA,

4-20 mA, 0-5 V ratiometric or 0-10 V transducers

AI8

analog input 8, which can be set via configuration

parameter for PTC, NTC, Pt 1000 probes, 0-20 mA,

4-20 mA, 0-5 V ratiometric or 0-10 V transducers

AI9

analog input 9, which can be set via configuration

parameter for PTC, NTC, Pt 1000 probes, 0-20 mA,

4-20 mA, 0-5 V ratiometric or 0-10 V transducers

AI10 analog input 4, which can be set via configuration

parameter for PTC, NTC or Pt 1000 probes

GND

ground analog inputs and outputs

AO4

analog output 4, which can be set via configuration

parameter for 0-20 mA, 4-20 mA or 0-10 V

AO5

analog output 5, for 0-10 V

AO6

analog output 6, for 0-10 V

DIGITAL OUTPUTS

Digital outputs.

Part Meaning

CO1

common digital output 1

NO1

normally open contact digital output 1

according to the model:

-

3 res. A @ 250 VAC electromechanical relay

-

24 VAC/DC, 600 mA max. command for solid

state relay

CO2

common digital output 2

NO2

normally open contact digital output 2

according to the model:

-

3 res. A @ 250 VAC electromechanical relay

-

24 VAC/DC, 600 mA max. command for solid

state relay

CO3-6 common digital outputs 3... 6

NO3

normally open contact digital output 3 (3 res. A @

250 VAC electromechanical relay)

NO4

normally open contact digital output 4 (3 res. A @

250 VAC electromechanical relay)

NO5

normally open contact digital output 5 (3 res. A @

250 VAC electromechanical relay)

NO6

normally open contact digital output 6 (3 res. A @

250 VAC electromechanical relay)

CO7

common digital output 7

NO7

normally open contact digital output 7 (3 res. A @

250 VAC electromechanical relay)

Description

The following drawing shows the aspect of the devices.

17

digital outputs K8 and K9

18

digital output K10