EVCO EVK802P7 User Manual

Page 2

EVCO S.p.A.

This document belongs to Evco; unless you are authorized by Evco, you can not publish it.

Via Mezzaterra 6, 32036 Sedico Belluno ITALY

Evco does not take any responsibility about features, technical data and possible mistakes related in this document or coming by its use.

Phone +39-0437-852468 • Fax +39-0437-83648

Evco does not take any responsibility about damages coming by the non-observance of the additional information.

[email protected] • www.evco.it

Evco reserves the right to make any change without prior notice and at any time without prejudice the basic safety and operating features.

PT • 48/10

9

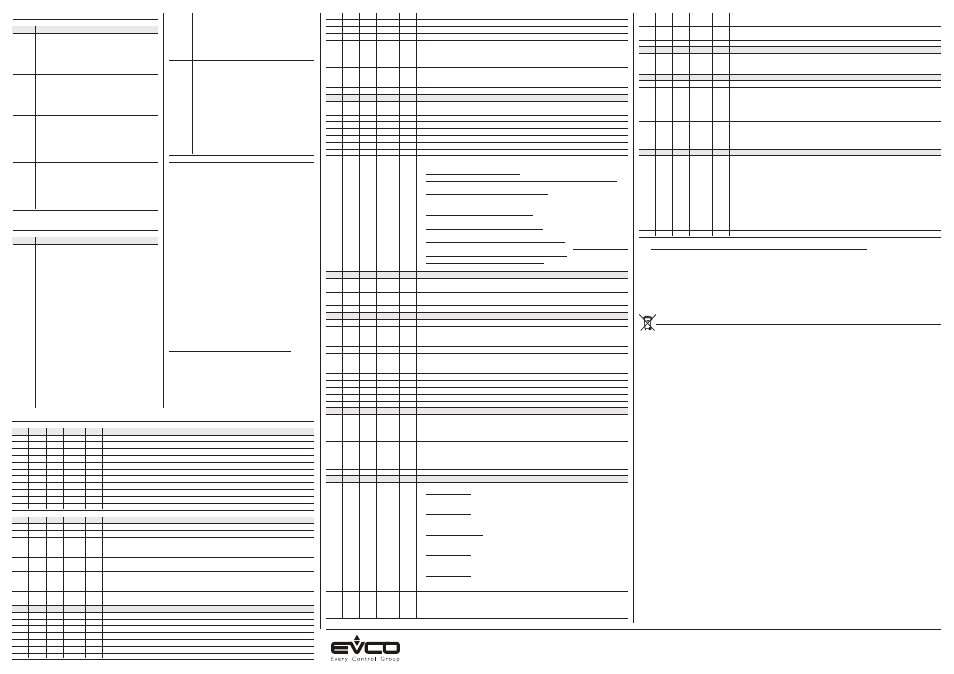

CONFIGURATION PARAMETERS

9.1 First level configuration parameters

PARAM. MIN.

MAX.

M.U.

DEF.

r0

0,1

15,0

°C/°F (1) 2,0

r1

1

600

min

90

r2

1

600

min

240

r3

-99,0

99,0

°C/°F (1) 3,0

r4

-99,0

99,0

°C/°F (1) -18,0

r5

1

600

min

90

r6

1

600

min

240

r7

-99,0

99,0

°C/°F (1) 0,0

r8

-99,0

99,0

°C/°F (1) -40,0

r9

-99,0

99,0

°C/°F (1) 2,0

rA

-99,0

99,0

°C/°F (1) -20,0

9.2 Second level configuration parameters

PARAM. MIN.

MAX.

M.U.

DEF.

CA1

-25,0

25,0

°C/°F (1) 0,0

CA2

-25,0

25,0

°C/°F (1) 0,0

P0

0

1

- - -

0

P1

0

1

- - -

1

P2

0

1

- - -

0

P3

0

1

- - -

1

PARAM. MIN.

MAX.

M.U.

DEF.

r0

0,1

15,0

°C/°F (1) 2,0

r1

1

600

min

90

r2

1

600

min

240

r3

-99,0

99,0

°C/°F (1) 3,0

r4

-99,0

99,0

°C/°F (1) -18,0

r5

1

600

min

90

r6

1

600

min

240

6

ALARMS

6.1 Alarms

CODE MESSAGE

AL

Minimum temperature alarm

Remedies:

• check the cabinet temperature

• check parameters A1 and A2

Consequences:

• the device will continue to function normally

AH

Maximum temperature alarm

Remedies:

• check the cabinet temperature

• check parameters A3 and A4

Consequences:

• the device will continue to function normally

id

Micro-port input alarm (only in "stand-by" mode and if

parameter i0 is set to 0 or 1)

Remedies:

• check the causes which activated the input

• check parameters i0 and i1

Consequences:

• the outcome set by parameter i0

iA

Compressor protection input alarm (only if parameter i0 is

set to 2)

Remedies:

• check the causes which activated the input

• check parameters i0 and i1

Consequences:

• the compressor will be shut down

When the cause that triggered the alarm has been resolved, the device

restores normal operation.

7

INTERNAL DIAGNOSTICS

7.1 Internal diagnostics

CODE MESSAGE

Pr1

Cabinet probe error

Remedies:

• see P0 parameter

• check probe integrity

• check probe-device connection

• check the cabinet temperature

Consequences if the error occurs while in "stand-by" mode:

• if parameter C11 is set to 0, it will not be possible to start

any of the cycles

• if parameter C11 is set to 1, the pin probe will function as

the cabinet probe and only timed cycles will be allowed

to start

Consequences if the error occurs during a timed chilling

operation:

• if parameter C11 is set to 0, the cycle will be interrupted

• if parameter C11 is set to 1, the pin probe will function as

the cabinet probe and the chilling operation will con-

tinue

Consequences if the error occurs during a set-temperature

chilling operation:

• if parameter C11 is set to 0, the cycle will be interrupted

• if parameter C11 is set to 1, the pin probe will function as

both the cabinet probe and pin probe and the chilling

operation will continue

Consequences if the error occurs during a storage opera-

tion:

• parameter C11 is set to 0, the compressor activity will

depend on parameters C4, C5 and C6

• if parameter C11 is set to 1, the pin probe will function as

the cabinet probe and the storage operation will con-

tinue

Pr2

Pin probe error

Remedies:

• the same as for the previous case, but in relation to the pin

probe

Consequences if the error occurs while in "stand-by" mode:

• only timed operation cycles will be allowed to start

Consequences if the error occurs during a timed chilling

operation:

• chilling will continue

Consequences if the error occurs during a set-temperature

chilling operation:

• chilling will continue in timed mode

Consequences if the error occurs during storage mode:

• storage will continue

8

TECHNICAL DATA

8.1 Technical data

Case: grey self-extinguishing.

Front panel protection classification (use copper conduc-

tors only): IP 65.

Connections: Screw terminal blocks (power supply, inputs and out-

puts), 6 pin connector (serial port; available on request); extractable

terminal block (power supply, inputs and outputs) available on re-

quest.

Operating temperature: from 0 to 55 ºC (10 ... 90% relative humid-

ity, without condensation).

Power supply: 230 VAC, 50/60 Hz, 3 VA (nominal); 115 VAC or

12-24 VAC/DC or 12 VAC/DC by request.

Insulation class: 2.

Alarm buzzer: integrated.

Sensor inputs: 2 (cabinet probe and pin probe) for PTC/NTC probes.

Digital inputs: 1 (door switch/multifunction) for NA/NC contact (clean

contact, 5 V 1 mA).

Sensor range: from -50.0 to 150.0 ºC for PTC probes, from -40.0 to

105.0 ºC for NTC probes.

Sensitivity: 0.1ºC/1ºC/1ºF.

Digital outputs: 2 relays:

• compressor relay: 16 A res. @250 VAC, 5 FLA,

30 LRA (NA contact) versions with 12 VAC/DC and

12-24 VAC/DC; 8 A res. @ 250 VAC, 2 FLA, 12 LRA

otherwise

• defrosting/evaporator fan relay: 8 A res.

@250 VAC, 2 FLA, 12 LRA (exchange contacts).

The maximum permitted current on loads is 10 A.

Serial port: port for communicating with the monitoring system (by

means of a serial interface, via TTL, using the MODBUS communication

protocol) or with the programming key; available on request.

MAIN CONTROLLER

parameter r7, r8, r9 and Ra differential

timed positive blast chilling duration

timed negative blast chilling duration

positive blast chill end-point temperature (temperature detected by the pin probe)

negative blast chill end-point temperature (temperature detected by the pin probe)

set-temperature positive blast chilling maximum duration

set-temperature negative blast chilling maximum duration

positive blast chilling operational setpoint (cabinet temperature)

negative blast chilling operational setpoint (cabinet temperature)

post positive blast chill storage operational setpoint (cabinet temperature)

post negative blast chill storage operational setpoint (cabinet temperature)

SENSOR INPUTS

cabinet probe offset

pin probe offset

probe type

0 = PTC

1 = NTC

degree Celsius decimal point (for the quantity displayed during normal operation)

1 = YES

unit of temperature measurement (2)

0 = °C

1 = °F

pin probe enabling

1 = YES

MAIN CONTROLLER

parameter r7, r8, r9 and Ra differential

timed positive blast chilling duration

timed negative blast chilling duration

positive blast chill end-point temperature (temperature detected by the pin probe)

negative blast chill end-point temperature (temperature detected by the pin probe)

set-temperature positive blast chilling maximum duration

set-temperature negative blast chilling maximum duration

r7

-99,0 99,0

°C/°F (1) 0,0

r8

-99,0

99,0

°C/°F (1) -40,0

r9

-99,0

99,0

°C/°F (1) 2,0

rA

-99,0

99,0

°C/°F (1) -20,0

rb

0

2

- - -

1

rc

0,0

99,0

°C/°F (1) 5,0

rd

1

99

s

60

PARAM. MIN.

MAX. M.U.

DEF.

C0

0

240

min

0

C1

0

240

min

5

C2

0

240

min

3

C3

0

240

s

0

C4

0

240

min

10

C5

0

240

min

10

C6

0

240

min

20

C11

0

1

- - -

0

PARAM. MIN.

MAX. M.U.

DEF.

d0

0

99

h

8

d3

0

99

min

30

d7

0

15

min

2

PARAM. MIN.

MAX. M.U.

DEF.

A1

0,0

99,0

°C/°F (1) 10,0

A2

0

1

- - -

1

A4

0,0

99,0

°C/°F (1) 10,0

A5

0

1

- - -

1

A6

0

240

min

15

A7

0

240

min

15

A8

0

240

min

15

A9

0

240

min

15

AA

0

240

s

5

PARAM. MIN.

MAX. M.U.

DEF.

F0

0

2

- - -

2

F2

0

2

- - -

1

F8

0

99

min

0

PARAM. MIN.

MAX. M.U.

DEF.

i0

0

4

- - -

1

i1

0

2

- - -

2

i2

-1

120

min

30

i3

-1

120

min

15

i7

0

120

min

0

PARAM. MIN.

MAX. M.U.

DEF.

u0

0

1

- - -

1

PARAM. MIN.

MAX. M.U.

DEF.

LA

1

247

- - -

247

Lb

0

3

- - -

2

LP

0

2

- - -

2

PARAM. MIN.

MAX. M.U.

DEF.

E0

0

3

- - -

1

E9

0

1

- - -

1

(1) the unit of measurement depends on parameter P2

(2) set the parameters relating to the controllers appropriately after altering parameter P2

(3) the device stores the defrost interval count every 30 minutes; altering parameter d0 has effect of concluding the previous defrost interval or

manual defrost activation

(4) the temperature alarm functions are only enabled during storage operations

(5) the parameter differential is 2.0 ºC/4 ºF

(6) there are no temperature alarms during defrosting and drip draining, if they occur following defrost activation

(7) there is no maximum temperature alarm while door switch input is enabled, if occurring after input activation

(8) the evaporator fan will be shut down providing defrosting is not ongoing

(9) the compressor and/or ventilator fan are shut down 10 s after input activation

(10) the compressor is shut down 10 s after input activation.

The device must be disposed of in accordance with local regulations pertaining to the collection of electrical and electronic appliances.

positive blast chilling operational setpoint (cabinet temperature)

negative blast chilling operational setpoint (cabinet temperature)

post positive blast chill storage operational setpoint (cabinet temperature)

post negative blast chill storage operational setpoint (cabinet temperature)

kind of cycle enabled

0 = positive chilling

1 = positive chilling and negative chilling

2 = negative chilling

"temperature detected by the pin probe - temperature of the cabinet" difference for the first stage of the

test to check correct pin probe insertion (see paragraph 3.6)

0 = test will not be performed (neither the first nor second stages)

duration of the second stage of the test to check correct pin probe insertion (see paragraph 3.6)

COMPRESSOR PROTECTION

operational cycle deferred compressor start-up; deferred compressor power restoration also follow-

ing a power interruption during an operational cycle

minimum elapsed time period between two consecutive compressor start-up operations

minimum compressor shut-down time

minimum compressor start-up time

storage cabinet probe error compressor shut-down duration; see also C5 and C6 (only if C11 = 0)

positive storage cabinet probe error compressor start-up duration; see also C4 (only if C11 = 0)

negative storage cabinet probe error compressor start-up duration; see also C4 (only if C11 = 0)

pin probe operation during cabinet probe error

0 = pin probe

IF THE ERROR OCCURS IN "STAND-BY" MODE - it will not be possible to start any of the cycles

IF THE ERROR OCCURS DURING A TIMED OR SET TEMPERATURE BLAST CHILLING OPERATION - the

cycle will be interrupted

IF THE ERROR OCCURS DURING A STORAGE OPERATION - compressor activity will depend on

parameters C4, C5 and C6

1 = both pin probe and cabinet probe

IF THE ERROR OCCURS WHILE IN "STAND-BY" MODE - the pin probe will operate as a cabinet probe

and it will only be possible to start timed cycles

IF THE ERROR OCCURS DURING TIMED BLAST CHILLING - the pin probe will operate as a cabinet

probe and chilling will continue

IF THE ERROR OCCURS DURING SET-TEMPERATURE BLAST CHILLING - the pin probe will operate as

both a pin probe and as a cabinet probe and chilling will continue; it is recommended to

set the i0 parameter to 2 (COMPRESSOR PROTECTION)

IF THE ERROR OCCURS DURING A STORAGE OPERATION - the pin probe will operate as a cabinet

probe and storage will continue

DEFROST

defrost interval (3)

0 = regular periodic defrosting will never be enabled

defrost duration

0 = defrosting will never be enabled

drip-drain duration

TEMPERATURE ALARMS (4)

the temperature below which the minimum temperature alarm is activated; see also A2 (5)

minimum temperature alarm type

0 = no alarm

1 = depending on parameters r9 and rA (or "r9 - A1" and "rA - A1")

the temperature above which the maximum temperature alarm is activated; see also A5 (5)

maximum temperature alarm type

0 = no alarm

1 = depending on parameters r9 and rA (or "r9 + A4" and "rA + A4")

storage operation start-up temperature alarm delay

temperature alarm delay

drip-drain end maximum temperature alarm delay (6)

door switch input deactivation maximum temperature alarm delay (only if i0 = 0 or 1) (7)

blast chill completion buzzer duration

EVAPORATOR FAN (only if u0 = 1)

evaporator fan activity during chilling

0 = off

1 = on

2 = in parallel with the compressor

evaporator fan activity during storage

0 = off

1 = on

2 = in parallel with the compressor

evaporator fan start-up delay following defrost cycle start

DIGITAL INPUTS

digital input operation

0 = DOOR SWITCH INPUT - in this case parameters i1, i2 and i3 assume significance; enabling input will

cause the evaporator fan to be shut down (at most for the period of time set by i3 or until input will

be disabled) (8) (9)

1 = DOOR SWITCH INPUT - in this case parameters i1, i2 and i3 assume significance; enabling input will

cause the compressor and evaporator fan to be shut down (at most for the period of time set by i3

or until input will be disabled) (8) (9)

2 = COMPRESSOR PROTECTION - in this case, parameters i1 and i7 assume significance; the compressor

will be shut-down, the display will flash code "iA" and the buzzer will be activated (until the input

will be deactivated)

3 = DOOR SWITCH INPUT - in this case parameters i1, i2 and i3 assume significance; enabling input will

cause the evaporator fan to be shut down (at most for the period of time set by i3 or until input will

be disabled) (8)

4 = DOOR SWITCH INPUT - in this case parameters i1, i2 and i3 assume significance; enabling input will

cause the compressor and evaporator fan to be shut down (at most for the period of time set by i3

or until input will be disabled) (8) (10)

digital input contact type

0 = NA (input active with contact closed)

1 = NC (input active with contact open)

2 = no input

door switch input alarm activation delay (solo se i0 = 0 o 1)

-1= the alarm will not sound

door switch input activation effect maximum duration (only if i0 = 0 or 1)

-1= the effect will last until the input will be disabled

compressor protection deactivation compressor delay (only if i0 = 2)

DIGITAL OUTPUTS

service controlled by relay K2 (see paragraph 2.3)

0 = defrosting

1 = evaporator fan

SERIAL NETWORK (MODBUS)

device address

baud rate

0 = 2.400 baud

1 = 4.800 baud

2 = 9.600 baud

3 = 19.200 baud

parity

0 = none (no parity)

1 = odd

2 = even

ENABLING

quantity modifiable quickly before starting the cycle

0 = no quantity

1 = if you have selected a timed chilling cycle, the chilling duration

if you have selected a set-temperature chilling cycle, the chilling end-point temperature

2 = if you have selected a timed chilling cycle, the chilling duration and the chilling operational

setpoint

if you have selected a set-temperature chilling cycle, the chilling operational setpoint

3 = if you have selected a timed chilling cycle, the chilling duration and the chilling operational

setpoint

if you have selected a set-temperature chilling cycle, the chilling end-point temperature and the

chilling operational setpoint

reserved