EVCO EVF818P9 User Manual

Page 2

EVCO S.p.A. | Code 104F818E103 | Page 2 of 2 | PT 03 / 12

This document is exclusive property of EVCO; reproduction and disclosure are prohibited without express authorisation from EVCO.

EVCO is not liable for any features, technical data and possible errors stated in this document or deriving from use of the same.

EVCO cannot be considered liable for damages caused by failure to comply with warnings given in this document.

EVCO reserves the right to make any changes without forewarning, without jeopardising the basic safety and operating features.

EVCO S.p.A.

Via Feltre 81, 32036 Sedico (BL) ITALY

phone +39 0437 852468 | fax +39 0437 83648

email [email protected] | web www.evco.it

4.5

Showing the evaporator temperature

Operate as indicated in the paragraph “Showing the room

temperature” to select “Pb2”.

If the evaporator probe is not enabled, the label “Pb2“ will

not be shown.

4.6

Showing the condenser temperature

Operate as indicated in the paragraph “Showing the room

temperature” to select “Pb3”.

If the condenser probe is not enabled, the label “Pb3“ will

not be shown.

4.7

Showing the temperature read by needle

probe 1, by needle probe 2 and by needle

probe 3

Operate as indicated in the paragraph “Showing the room

temperature” to select “Pb4” (needle probe 1), “Pb5” (nee-

dle probe 2) or “Pb6” (needle probe 3).

If needle probe 1 is not enabled, the label “Pb4“ will not

be shown.

If needle probe 2 is not enabled, the label “Pb5“ will not

be shown.

If needle probe 3 is not enabled, the label “Pb6“ will not

be shown.

4.8

Activating the defrost by hand

Operate as follows:

1.

Make sure the device is in status “on”, a precooling or

a storing is running.

2.

Make sure the keyboard is not locked and no proce-

dure is running.

3.

Press and hold button UP 4 s: the 3 digits display will

show “dEF”.

If the evaporator probe is enabled and to the defrost acti-

vation the evaporator temperature is above the defrost cut

off temperature, the defrost will not be activated.

4.9

Switching on / off the room light by hand

Operate as follows:

1.

Make sure the function is enabled.

2.

Make sure no procedure is running.

3.

Press and release button BLAST FREEZING: LED AUX

will switch on / off.

4.10

Locking / unlocking the keyboard

To lock the keyboard operate as follows:

1.

Make sure no procedure is running.

2.

Press and hold button DOWN and button ON / STAND-

BY 2 s: the 3 digits display will show “Loc” 2 s.

To unlock the keyboard operate as follows:

3.

Make sure no procedure is running.

4.

Press and hold button DOWN and button ON / STAND-

BY 2 s: the 3 digits display will show “UnL” 2 s.

4.11

Silencing the buzzer

Operate as follows:

1.

Make sure no procedure is running.

2.

Press and release a button.

5

OPERATION

5.1

Temperature controlled blast chilling and

storing

To start the cycle operate as follows:

1.

Make sure the device is in status “on”.

2.

Make sure the keyboard is not locked and no proce-

dure is running.

3.

Press and release button BLAST CHILLING: LED

and LED

will flash.

4.1 According to the model, the 3 digits display will show

the blast chilling cutoff temperature or the 4 digits

display will show the blast chilling working setpoint.

4.2 Press and release button UP or button DOWN in 60 s

to modify these values.

5.

Press and release button START / STOP: LED

and

LED

will firmly remain switched on and it will be

started the test for the verification of the proper in-

sertion of the needle probe.

5.1 If the test is successfully completed, the cycle will be

started.

5.2 If the test is not successfully completed, the cycle will

be started time controlled.

To stop the cycle operate as follows:

6.

Press and hold button START / STOP 2 s.

5.2

Temperature controlled hard blast chilling

and storing

To start the cycle operate as follows:

1.

Make sure the device is in status “on”.

2.

Make sure the keyboard is not locked and no proce-

dure is running.

3.

Press and release button BLAST CHILLING: LED

and LED

will flash.

4.

Press and release button HARD / SOFT: LED HARD

will flash.

5.1 According to the model, the 3 digits display will show the

blast chilling cutoff temperature or the 4 digits display

will show the blast chilling working setpoint.

5.2 Press and release button UP or button DOWN in 60 s to

modify these values.

6.

Press and release button START / STOP: LED

, LED

and LED HARD will firmly remain switched on and

it will be started the test for the verification of the proper

insertion of the needle probe.

6.1 If the test is successfully completed, the cycle will be

started.

6.2 If the test is not successfully completed, the cycle will be

started time controlled.

To stop the cycle operate as follows:

7.

Press and release button START / STOP 2 s.

5.3

Time controlled blast chilling and storing

To start the cycle operate as follows:

1.

Make sure the device is in status “on”.

2.

Make sure the keyboard is not locked and no procedure

is running.

3.

Press and release button BLAST CHILLING: LED

and

LED

will flash.

4.

Press and release button TIME / TEMPERATURE: LED

will flash and LED

will switch off.

5.1 The 3 digits display will show the blast chilling duration.

5.2 Press and release button UP or button DOWN in 60 s to

modify this value.

6.

Press and release button START / STOP: LED

and LED

will firmly remain switched on and the cycle will be

started.

To stop the cycle operate as follows:

7.

Press and hold button START / STOP 2 s.

5.4

Time controlled hard blast chilling and storing

To start the cycle operate as follows:

1.

Make sure the device is in status “on”.

2.

Make sure the keyboard is not locked and no procedure

is running.

3.

Press and release button BLAST CHILLING: LED

and

LED

will flash.

4.

Press and release button HARD / SOFT: LED HARD will

flash.

5.

Press and release button TIME / TEMPERATURE again:

LED

will flash and LED

will switch off.

6.1 The 3 digits display will show the blast chilling duration.

6.2 Press and release button UP or button DOWN in 60 s to

modify this value.

7.

Press and release button START / STOP: LED

, LED

and LED HARD will firmly remain switched on and the

cycle will be started.

To stop the cycle operate as follows:

8.

Press and release button START / STOP 2 s.

5.5

Continuous blast chilling

To start the cycle operate as follows:

1.

Make sure the device is in status “on”.

2.

Make sure the keyboard is not locked and no procedure

is running.

3.

Press and release button BLAST CHILLING: LED

and

LED

will flash.

4.

Press and release button TIME / TEMPERATURE: LED

will flash and LED

will switch off.

5.

Press and release button TIME / TEMPERATURE again:

the 3 digits display will show “inF”.

6.

Press and release button START / STOP: LED

and LED

will firmly remain switched on and the cycle will be

started.

To stop the cycle operate as follows:

7.

Press and hold button START / STOP 2 s.

5.6

Temperature controlled blast freezing and stor-

ing

To start the cycle operate as follows:

1.

Make sure the device is in status “on”.

2.

Make sure the keyboard is not locked and no procedure

is running.

3.

Press and release button BLAST FREEZING: LED

, LED

, LED

and LED HARD will flash.

4.1 According to the model, the 3 digits display will show the

blast freezing cutoff temperature or the 4 digits display

will show the blast freezing working setpoint.

4.2 Press and release button UP or button DOWN in 60 s to

modify these values.

5.

Press and release button START / STOP: LED

, LED

, LED

and LED HARD will firmly remain

switched on and it will be started the test for the verifica-

tion of the proper insertion of the needle probe.

5.1 If the test is successfully completed, the cycle will be

started.

5.2 If the test is not successfully completed, the cycle will be

started time controlled.

To stop the cycle operate as follows:

6.

Press and release button START / STOP 2 s.

5.7

Temperature controlled soft blast freezing and

storing

To start the cycle operate as follows:

1.

Make sure the device is in status “on”.

2.

Make sure the keyboard is not locked and no procedure

is running.

3.

Press and release button BLAST FREEZING: LED

, LED

, LED

and LED HARD will flash.

4.

Press and release button HARD / SOFT: LED HARD will

switch off.

5.1 According to the model, the 3 digits display will show the

blast freezing cutoff temperature or the 4 digits display

will show the blast freezing working setpoint.

5.2 Press and release button UP or button DOWN in 60 s to

modify these values.

6.

Press and release button START / STOP: LED

, LED

and LED

will firmly remain switched on and

it will be started the test for the verification of the proper

insertion of the needle probe.

6.1 If the test is successfully completed, the cycle will be

started.

6.2 If the test is not successfully completed, the cycle will be

started time controlled.

To stop the cycle operate as follows:

7.

Press and release button START / STOP 2 s.

5.8

Time controlled blast freezing and storing

To start the cycle operate as follows:

1.

Make sure the device is in status “on”.

2.

Make sure the keyboard is not locked and no procedure

is running.

3.

Press and release button BLAST FREEZING: LED

, LED

, LED

and LED HARD will flash.

4.

Press and release button TIME / TEMPERATURE: LED

will flash and LED

will switch off.

5.1 The 3 digits display will show the blast freezing duration.

5.2 Press and release button UP or button DOWN in 60 s to

modify this value.

6.

Press and release button START / STOP: LED

, LED

, LED

and LED HARD will firmly remain switched

on and the cycle will be started.

To stop the cycle operate as follows:

7.

Press and release button START / STOP 2 s.

5.9

Time controlled soft blast freezing and storing

To start the cycle operate as follows:

1.

Make sure the device is in status “on”.

2.

Make sure the keyboard is not locked and no procedure

is running.

3.

Press and release button BLAST FREEZING: LED

, LED

, LED

and LED HARD will flash.

4.

Press and release button HARD / SOFT: LED HARD will

switch off.

5.

Press and release button TIME / TEMPERATURE: LED

will flash and LED

will switch off.

6.1 The 3 digits display will show the blast freezing duration.

6.2 Press and release button UP or button DOWN in 60 s to

modify this value.

7.

Press and release button START / STOP: LED

, LED

and LED

will firmly remain switched on and the

cycle will be started.

To stop the cycle operate as follows:

8.

Press and release button START / STOP 2 s.

5.10

Continuous blast freezing

To start the cycle operate as follows:

1.

Make sure the device is in status “on”.

2.

Make sure the keyboard is not locked and no procedure

is running.

3.

Press and release button BLAST FREEZING: LED

, LED

, LED

and LED HARD will flash.

4.

Press and release button TIME / TEMPERATURE: LED

will flash and LED

will switch off.

5.

Press and release button TIME / TEMPERATURE again:

the 3 digits display will show “inF”.

6.

Press and release button START / STOP: LED

, LED

, LED

and LED HARD will firmly remain switched

on and the cycle will be started.

To stop the cycle operate as follows:

7.

Press and hold button START / STOP 2 s.

5.11

Blast chilling intensity

To select the evaporator fan speed operate as follows:

1.

Make sure the function is enabled.

2.

Press and release button BLAST CHILLING INTENSITY:

the LED bars will provide information about the fan

speed.

5.12

Starting the precooling

To start the precooling operate as follows:

1.

Make sure the device is in status “on”.

2.

Make sure no procedure is running.

3.

Press and hold button BLAST CHILLING 2 s: LED will

flash.

To stop the precooling operate as follows:

4.

Press and hold button BLAST CHILLING 2 s or start an

operating cycle.

5.13

Switching on the UV light for the cycle of steri-

lization

Operate as follows:

1.

Make sure the function is enabled.

2.

Make sure the device is in status “on” and the door is

closed, or the door switch input is not active.

3.

Make sure the keyboard is not locked and no procedure

is running.

4.

Press and hold button BLAST FREEZING 2 s: LED AUX

will switch on.

5.14

Needle probe heating

Operate as follows:

1.

Make sure the device is in status “on” or a storing is

running and the door is open, or the door switch input is

active.

2.

Make sure the keyboard is not locked and no procedure

is running.

3.

Press and hold button BLAST CHILLING INTENSITY 2 s:

LED

will flash and LED AUX will switch on.

6

FUNCTION “PROGRAMS”

6.1

Storing a program

Operate as follows:

1.

Make sure the keyboard is not locked and no procedure

is running.

2.

Press and hold button PROGRAMS 2 s before starting an

operating cycle or during a storing: the 1 digit display

will show the number of the first available program (if

the display shows “F”, it will mean all the programs will

already be used; in this case it will be necessary to

overwrite an existing program).

3

Press and release button UP or button DOWN in 60 s to

select the program number.

4.

Press and release button PROGRAMS: the 1 digit display

will switch off.

To quit the procedure operate as follows:

5.

Do not operate 60 s (press and release button PROGRAMS

if all the programs are already used).

6.2

Starting a program

Operate as follows:

1.

Make sure the device is in status “on”.

2.

Make sure the keyboard is not locked and no procedure

is running.

3.

Press and release button PROGRAMS: the 1 digit display

will show the number of the first available program and

the dedicated LED will flash (if the display remains

switched off, it will mean no program will be available).

4.

Press and release button UP or button DOWN in 60 s to

select the program number.

5.

Press and release button START / STOP: the dedicated

LED will firmly remain switched on and the cycle will be

started with the settings stored in the program.

7

SIGNALINGS AND INDICATIONS

7.1

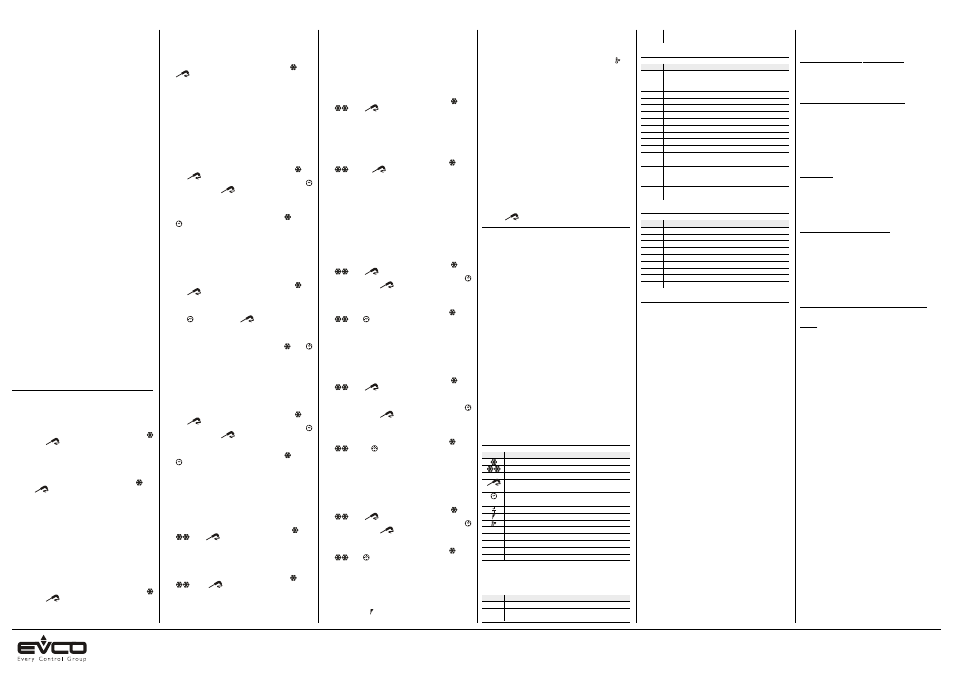

Signalings

LED

Meaning

LED blast chilling

LED blast freezing

HARD LED hard blast chilling / blast freezing

LED temperature controlled blast chilling / tempera-

ture controlled blast freezing

LED time controlled blast chilling / time controlled

blast freezing

LED storing

LED bars blast chilling intensity

LED precooling

AUX LED auxiliary

HACCP LED HACCP

°C

LED Celsius degree

°F

LED Fahrenheit degree

min

LED minutes

If button ON / STAND-BY is switched on, it will mean the

device will be in status “stand-by”.

7.2

Indications

Code Meaning

dEF

A defrost is running

Loc

The keyboard is locked; look at paragraph “Locking

/ unlocking the keyboard”

UnL

The keyboard has been unlocked; look at paragraph

“Locking / unlocking the keyboard”

8

ALARMS

8.1

Alarms

Code Meaning

tiM

Alarm temperature controlled blast chilling or tem-

perature controlled blast freezing not concluded

within the maximum duration (HACCP alarm)

AL

Low temperature alarm

AH

High temperature alarm (HACCP alarm)

id

Open door alarm

HP

High pressure alarm

LP

Low pressure alarm

CtH

Compressor thermal switch alarm

PF

Lack of power supply alarm (HACCP alarm)

COH Overheated condenser alarm

CSd

Locked compressor alarm

ESt

Alarm download of the configuration parameters not

successfully completed

CEr

Alarm firmwares of the configuration parameters

contained in EVKEY not coinciding with that of the

device

Erd

Alarm upload of the configuration parameters not

successfully completed

9

Errors

9.1

Errors

Code Meaning

Pr1

Room probe error

Pr2

Evaporator probe error

Pr3

Condenser probe error

Pr4

Needle probe 1 error

Pr5

Needle probe 2 error

Pr6

Needle probe 3 error

rtc

Real time clock error

ErC

Error compatibility user interface-control module

ErL

Error communication user interface-control module

10

TECHNICAL DATA

10.1

Technical data

Purpose of the devices: controller for blast chillers.

Execution:

-

user interface: open frame board behind a sheet of meth-

acrylate

-

control module: open frame board.

Size:

-

user interface: 340.0 x 84.0 x 36.5 mm (13.385 x 3.307

x 1.437 in; W x H x D)

-

control module: 166.0 x 116.0 x 44.0 mm (6.535 x 4.566

x 1.732 in; W x H x D).

Installation:

-

user interface: by back panel, with threaded studs

-

control module: on flat surface, with spacers.

Index of protection:

-

user interface: IP65

-

control module: IP00.

Connections:

-

user interface: fix screw terminal blocks (control mod-

ule)

-

control module: extractable screw terminal blocks (user

interface, power supply, inputs, outputs, except the out-

put for the compressor management and RS-485 serial

port), faston 6.3 mm (0.248 in) wide (output for the com-

pressor management), 6 poles connector (TTL serial port).

The maximum lengths of the connecting cables user inter-

face-control module is 20 m (65.614 ft).

Operating temperature: from 0 to 55 °C (from 32 to

131 °F).

Storage temperature: from -25 to 60 °C (from -13 to 140

°F).

Operating humidity: from 10 to 90% of relative humidity

not condensing.

Pollution situation: 2.

Power supply:

-

user interface: supplied by the control module

-

control module: 115... 230 VAC (±15%), 50 / 60 Hz,

(±3 Hz), 10 VA max.

Overvoltage category: III.

Real time clock: incorporated (with capacitor).

Battery autonomy in the event of lack of power supply:

24 h with battery fully charged.

Battery charging time: 2 min (the battery is charged by the

power supply of the device).

Signaling and alarm buzzer: incorporated.

Analog inputs: 6 inputs (room probe, evaporator probe,

condenser probe and “multipoint” needle probe up to three

sensors), which can be set via configuration parameter for

PTC / NTC probes.

PTC analog inputs (990

Ω

@ 25 °C, 77 °F)

Kind of sensor:

KTY 81-121.

Working range:

from -50 to 150 °C (from -58

to 302 °F).

Resolution:

1 °C (1 °F).

Protection:

none.

NTC analog inputs (10K

Ω

@ 25 °C, 77 °F)

Kind of sensor:

ß3435.

Working range:

from -40 to 105 °C (from -40

to 220 °F).

Resolution:

1 °C (1 °F).

Protection:

none.

Digital inputs: 4 inputs (door switch, high pressure switch,

low pressure switch and compressor thermal switch), which

can be set via configuration parameter for normally open /

normally closed contact (free of voltage contact,

5 VDC, 2 mA).

Digital inputs

Power supply:

none.

Protection:

none.

Displays: 3 + 4 + 1 digits custom display, with function

icons.

Analog outputs: 1 PWM output for evaporator fan man-

agement.

Digital outputs:

8 outputs (electromechanical relays)

-

1 SPST 30 res. A @ 250 VAC output (K1) for compres-

sor management

-

six 8 res. A @ 250 VAC outputs of which 5 SPST out-

puts for defrost management (K2), evaporator fan

management (K3), condenser fan management (K4),

room light or UV light management (K7), pump down

or alarm output management (K8) and 1 SPDT output

for door heater management (K5)

-

1 SPDT 16 res. A @ 250 VAC output (K6) for needle

probe heater management.

The maximum current allowed on the loads is 20 A.

Type of actions and additional features: 1C.

Communication ports:

2 ports

-

1 TTL serial port

-

1 RS-485 serial port with MODBUS communication

protocol.