Dynaflite DYFA3040 User Manual

Page 25

satisfied with the fit, glue the dowels into the

wing with 6-minute epoxy. Use caution not to

get any epoxy on the fuselage.

Q 13. Using the leading edge wing skins you

prepared earlier, sheet the bottom LE of both

wing panels. We find it easiest to use aliphatic

resin on the ribs and medium CA on the spar.

Thin CA can then be used on the LE.

Q 14. Using 3/32" x 3" x 36" balsa, sheet the bottom

center of the wing from W3 to W3. Using one

continuous piece across the entire center-section

will increase the strength of the joint.

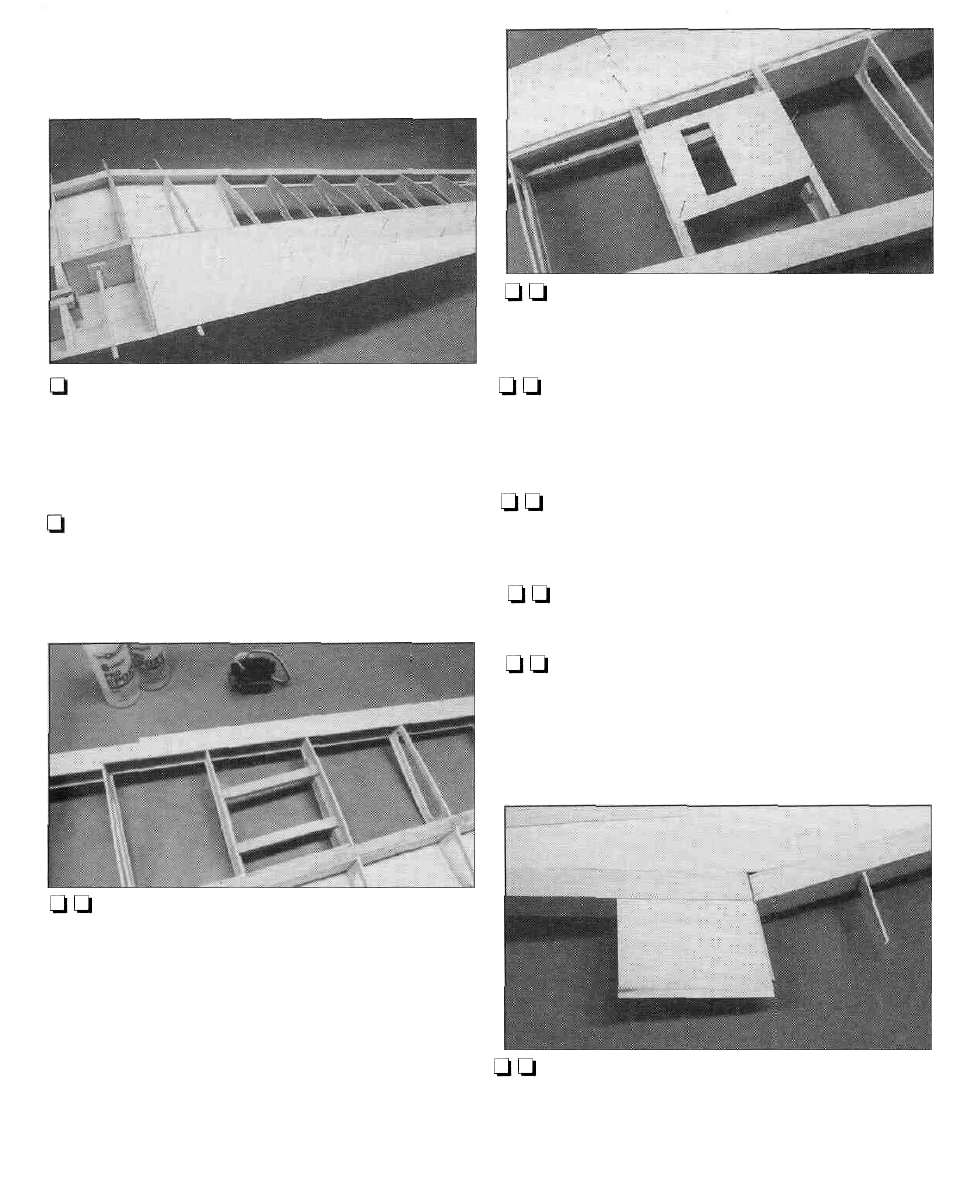

Q Q 15. Working on the left wing panel, build

the aileron servo mount between ribs W8 and

W9. Cut two servo mount rails from the 1/4" x

3/8" x 44" basswood shim stick used earlier. Cut

two 3-3/4" long bracing strips from die-cut 1/8"

ply servo rail brace strip. Fit and glue these

pieces into place, spacing the rails to fit the

servo you will be using. Position the rails so the

top of the servo will protrude below the wing

the desired amount.

Q Q 16. Sheet the area around the servo using

leftover 3/32" x 3" balsa.This gives the covering

a place to adhere to.

Oil-] 17. If you are installing flaps on your Chipmunk,

build the flap servo mount between ribsW4 and

W5 as you did above for the aileron servo. Sheet

the area around the servo.

Q l-l 18. Using 3/32" x 1/4" x 30" balsa strips cut,

fit and glue cap strips on the bottom of ribs

W 4 - W 7 a n d W 1 0 - W 1 2 .

Q t-1 19. Cap strip ribs W8 and W9 where there

is no sheeting.

Q Q 20. Locate a 1-1/2" x 1-5/8" x 9-1/2" balsa

block. Shape the block to the outline of the wing

tip using the plan as a guide. Glue the block

onto tip rib W12. Rough carve and sand the

wing tip block to shape.

l-l l-l 21. Use some leftover 3/32" x 3" sheeting to

cut aTE sheet to go between ribs W1, W2 and

W2A (W2A is added in the next step). Use the

25