Preflight, Set the control throws, At home – Dynaflite GPMA0090 Butterfly User Manual

Page 37

37

battery pack aft. If possible arrange the battery

pack and receiver to achieve balance but make

sure they remain secure in the fuselage so they

cannot shift during fl ight or a rough landing. If you

must add additional weight to the nose or tail of

the Butterfl y to achieve balance use Great Planes

adhesive lead weights (GPMQ4485). An alternative

to stick-on nose weight (if your model is tail heavy)

is a Great Planes brass spinner nut (GPMQ4640).

It has 1/4-28 threads so it will fi t most engines.

Set the Control Throws

Measure the throws at the widest part of the

trailing edge of the rudder and elevator. After

a few fl ights you may change the throws to suit

your fl ight style or the weather conditions.

We recommend the following control surface

throws:

Elevator:

3/4" up and down

Rudder:

1-1/2" left and right

Throttle:

Set the throttle so that at “high stick”

the carburetor barrel is fully open and at low

stick with full to half throttle

trim

, the carburetor

barrel is nearly closed. At this position the engine

should run reliably at a low RPM (idle). To shut

the engine off, decrease the throttle trim tab.

results in more throw.

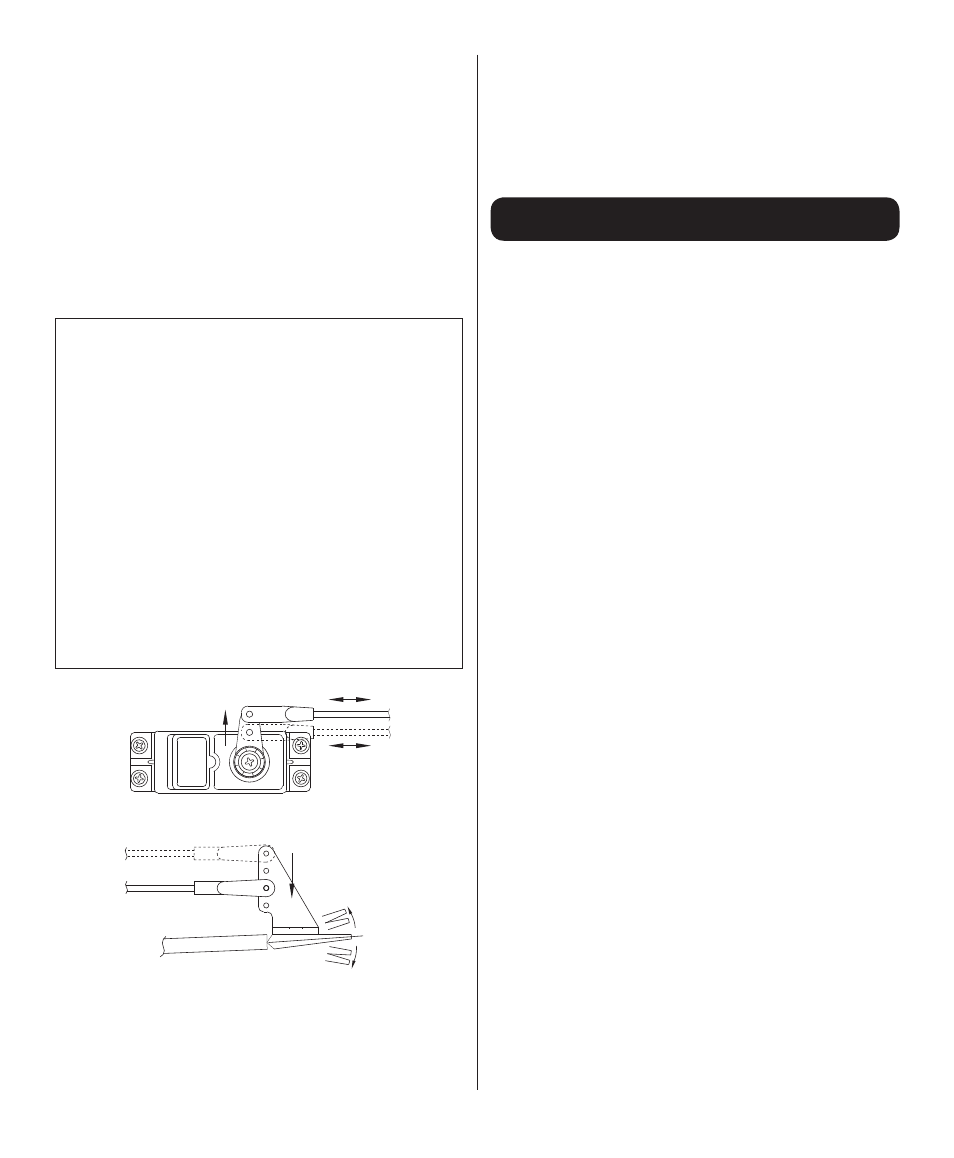

Moving the clevis inward on the control horn

throw

More

throw

More

More

movement

results in more pushrod movement.

Moving the clevis outward on the servo arm

Less

movement

More movement

The closer the clevis is to the base of the control

horn on the control surface and/or the further the

pushrod is from the center of the servo arm, the

more control throw you will have. To decrease

control throw, move the clevis on the control horn

outward and/or move the pushrod on the servo arm

inward. Combinations of the above arrangements

will provide the control throw you require. Of course,

if your transmitter has ATV (adjustable travel

volume), use them to fi ne-tune the control throws.

Preflight

At Home

Balance Your Propellers

Balancing the propeller seems like one of those

things that you can skip, but many problems are

the result of vibration caused by an unbalanced

propeller. Nuts and bolts can vibrate loose and

vibration can damage delicate radio components

inside your receiver and servos. Vibration can even

damage the delicate glow plug element which could

result in an engine that is diffi cult or impossible

to start. Purchase a Top Flite Precision Magnetic

Balancer™ (TOPQ5700) or a Great Planes fi ngertip

prop balancer (GPMQ5000) to accurately balance

your propellers.

Charge Your Batteries

Follow the battery charging instructions in the

instruction manual that came with your radio control

system. You should

always

charge your batteries

the night before you fl y.

Ground Check Your Model

Inspect all nuts, screws and wheel collars.

Make

sure you install the screw that holds the servo

arm onto the servos

and the servo cords are

securely connected to the receiver.

If you are not thoroughly familiar with R/C models,

ask an experienced modeler to inspect your radio

installation and make sure the control surfaces

respond correctly. The engine must be “broken-

in” according to the engine manufacturer’s

recommendations for break-in. Refer to the

Engine

Safety Precautions

on page 42 before you start

your engine. After you run the engine on the model

make sure all screws remain tight, the hinges are

secure and the prop is on tight.