Dynaflite GPMA0090 Butterfly User Manual

Page 34

34

FasLink

2-56 (.074") Pushrod Wire

Servo Horn

1/16"

❏ ❏

6.

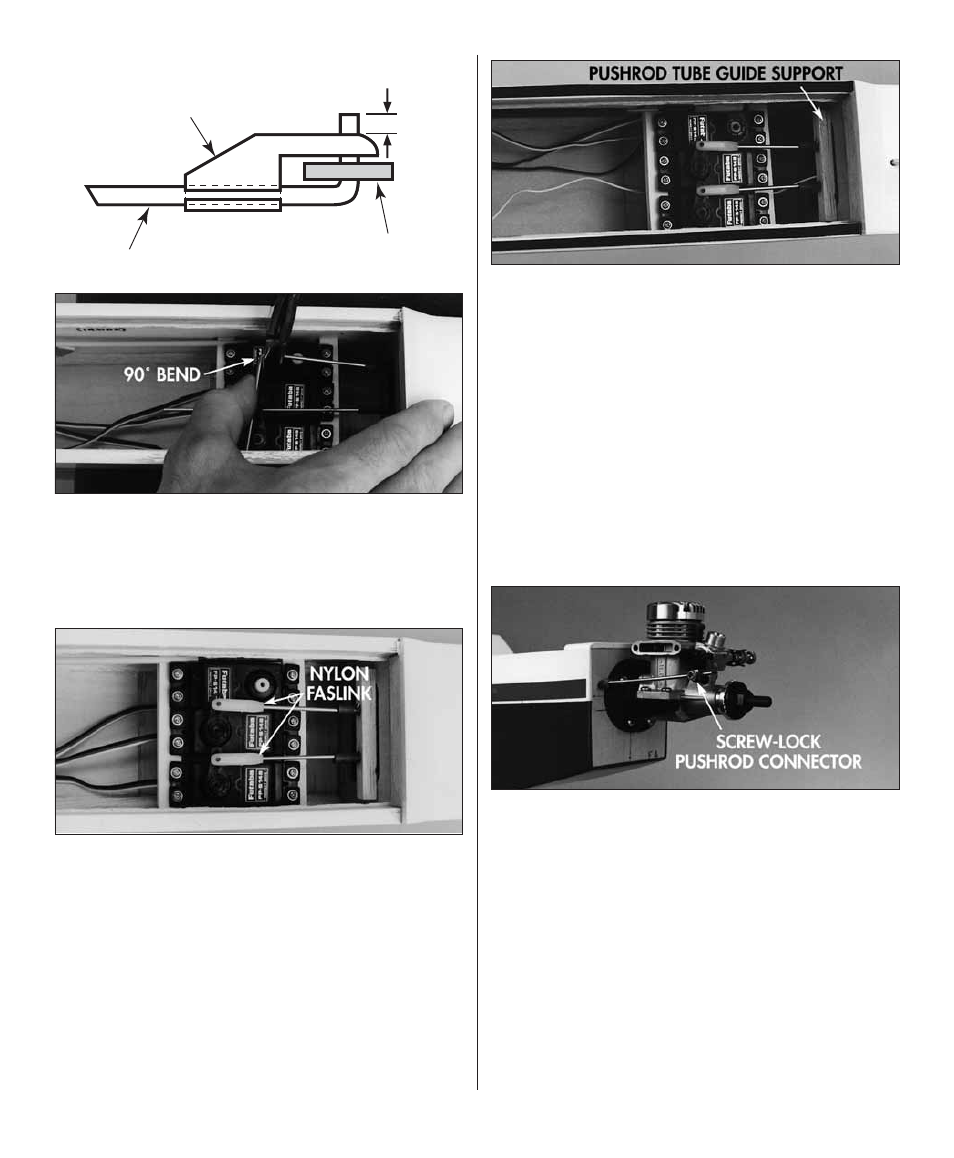

Disconnect the clevis from the elevator horn,

then make a 90-degree bend in the pushrod at the

mark. Snap a FasLink™ Pushrod Keeper (included)

onto the pushrod. Cut the wire so it protrudes from

the FasLink by 1/16" as shown in the sketch.

❏ ❏

7.

If necessary, enlarge the holes in the servo

arm with a hobby knife or a 5/64" drill bit, then

connect the pushrod to the elevator servo arm

from the bottom

and secure it with a FasLink.

Adjust the clevis so the elevator is centered, then

fi t a silicone retainer on the clevis and connect the

clevis to the elevator control horn.

❏ ❏

8.

Connect the rudder pushrod to the servo

and rudder the same way.

❏ ❏

9.

Glue the forward pushrod guide tube support

to F-7, then glue the pushrod guide tubes to the

support with medium or thin CA.

❏

10

. Install the engine mount on the fi rewall. Attach

the engine to the mount.

❏

11.

Sand the 12" outer throttle guide tube so

glue will stick. Insert the tube through the holes

in the fi rewall and F-6. Cut a 36" rod (threaded

one-end) to a length of 17" including the threaded

end. Thread a nylon clevis onto the wire pushrod,

then install the pushrod so the non-threaded end

protrudes from the fi rewall.

❏

12.

Connect the clevis to the servo arm, then

connect the front of the throttle pushrod to the

carburetor arm with a Great Planes Screw-Lock™

Pushrod Connector (included). The pushrod may

require a couple of small bends to align with the

pushrod connector. Cut off the excess wire so

approximately 1/4" protrudes from the connector.

❏

13.

Glue the outer throttle pushrod guide tube

to the fi rewall and F-6 with thin CA.