Carrier EVERGREEN 19XR User Manual

Page 2

2

If the chiller software is an earlier version than is supported

by the EverVu display, the chiller software will need to be up-

graded to match the version of EverVu database that will be

cloned during the installation of the display.

If the chiller software is a later version than is supported by

the EverVu display, a new EverVu database will need to be

downloaded and imported into the EverVu display. Contact a

Carrier Service office for assistance in importing the databases.

INSTALLATION

Equipment Needed

•

3

/

16

in. hex screwdriver

•

1

/

4

-20-1 in. hex bolts

• Voltmeter

Step 1 — Identify Power Supply

POWER REQUIREMENTS — The EverVu™ panel is pro-

vided with a 25-ft Beldon power cable and plug for connection

to a 120-v receptacle. If 120-v receptacle is available, proceed

to Step 2. If 120-v receptacle is not available, power may be

obtained directly from the chiller power panel by following the

instruction below.

Connecting Power Cable to Chiller Power Panel — The

following instructions are for connecting the power cable of the

display panel directly to the 110-v supply at the chiller power

panel. If the power cable of the display can be connected to a

120-v receptacle, this step is not necessary; proceed to Step 2.

1. Identify the oil heater contactor (1C) in the chiller power

panel.

2. Using a voltmeter, check the voltage across Terminals

22 and 23. The voltage should be 110 v

10%. If the

voltage is not within this range, STOP immediately

and consult an appropriate electrical specialist.

3. Using a voltmeter, verify that Terminal 23 in oil heater

contractor is neutral. If not, STOP immediately and

consult an appropriate electrical specialist.

4. After verifying voltages in Steps 2 and 3, turn off

chiller power and verify that the oil heater contractor is

deenergized and no voltage is present at the input

Terminals 22 and 23.

5. LOCK OUT and TAG OUT power supply to the chill-

er power panel.

6. Remove the plug of the display panel power cord with a

wire cutter.

7. Strip approximately 6 in. of insulation off power cable

end.

8. Using two fork connectors (red and blue), crimp accord-

ing to the following color code:

a. WHITE wire to RED connector

b. BLACK wire to BLUE connector.

9. Strip the insulation off the green grounding wire.

10. Remove the electrical knockout from the panel and

add a strain relief connection, if necessary.

11. Pulls the wires through strain relief and connect the

green grounding wire to the grounding lug. Connect

the fork terminals to the input of the oil heater circuit

breaker as follows:

a. 1C-22 to RED fork terminal (WHITE wire)

b. 1C-23 to BLUE fork terminal (BLACK wire).

12. For safety reasons, do not remove LOCK OUT and TAG

OUT until completing Step 5 — Connect Cable Between

Display and ICVC (International Chiller Visual Control).

Step 2 — Assemble Swing Arm —

Refer to sepa-

rate Swing Arm Assembly Instructions provided in package.

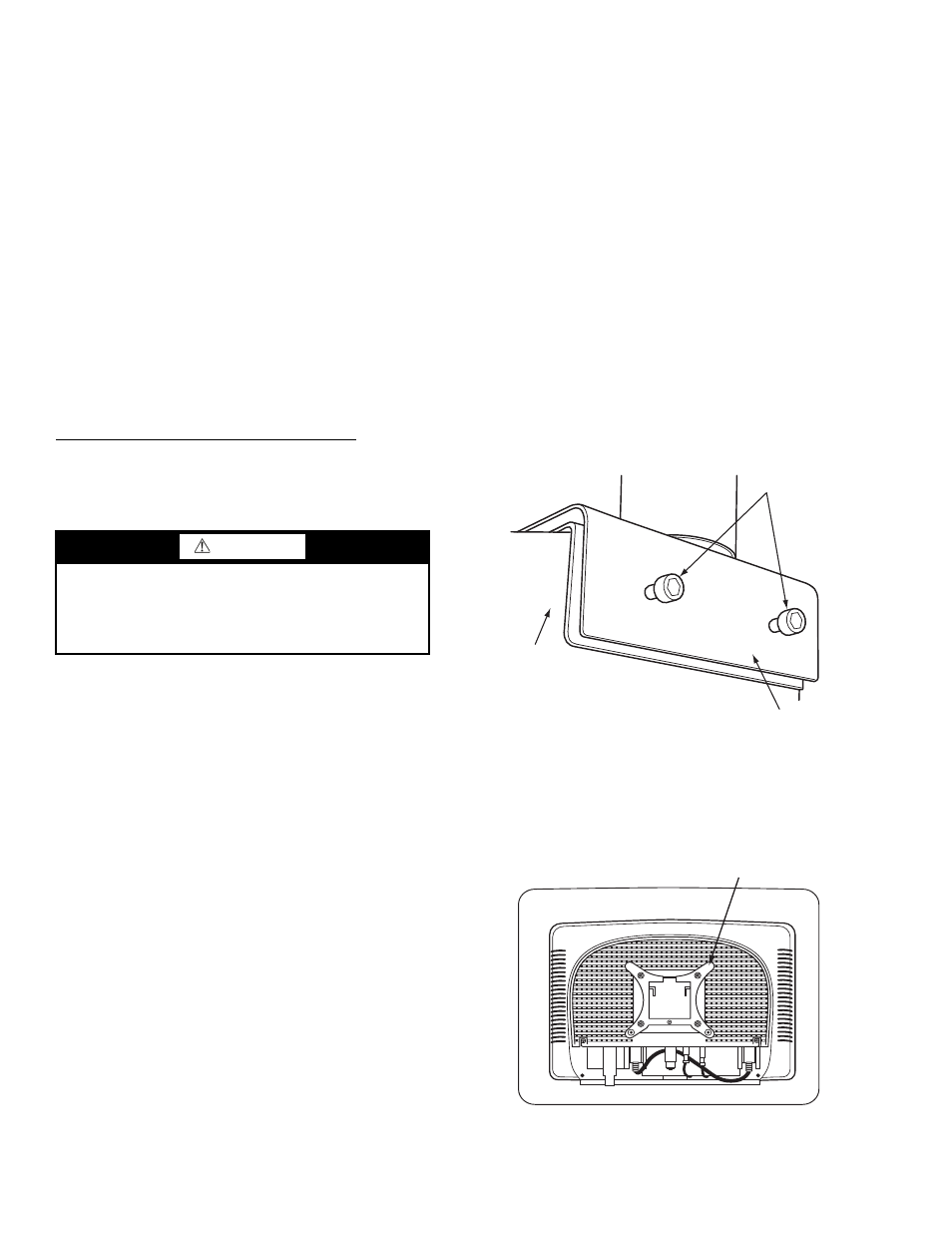

Step 3 — Attach Arm to Tube Sheet

1. Identify the tube sheet on the evaporator (19XR,XRV) or

condenser (23XRV) where the display is to be mounted.

Insert the bolt into the center hole of the tube sheet

mounting bracket.

NOTE: Do not remove the white plastic piece inside

the mounting bracket. This serves to insulate the metal

between the tube sheet and mounting bracket.

2. Attach the

1

/

4

-20-1 in. hex bolts halfway through in the

base of the mounting bracket. Do not tighten com-

pletely.

3. Align the arm mounting bracket to the tube sheet and

tighten hex bolts using a

3

/

16

hex screwdriver. See Fig. 1.

Step 4 — Mount Display Screen on Arm

Mounting Bracket —

Locate the EverVu display panel.

Do not remove the plastic covering until you are ready to start

up the touch screen. The display screen is shipped with the

quick connect mount attached to the back of the screen. See

Fig. 2.

WARNING

Electrical shock can cause personal injury and death. Shut

off all power to this equipment during installation. There

may be more than one disconnect switch. Tag all discon-

nect locations to alert others not to restore power until work

is completed.

Fig. 1 — Attach Arm to Tube Sheet

MOUNTING

BOLTS

TUBE

SHEET

ARM BASE

a19-1891

Fig. 2 — Display Panel with Mount Attached

BACK OF DISPLAY PANEL

DISPLAY MOUNT

a19-1890