Carrier AQUAZONE 50VS User Manual

Page 9

9

The direct return system shows the most common piping ar-

rangement. This is the most cost effective method of piping to

install since the water is supplied and returned to a riser column

at the same place, at the bottom or top of the building. Howev-

er, this type of system requires more effort to individually bal-

ance water flow to the units. The risers are normally capped at

the ends opposite the main supply and return piping and may

require a field-installed flush and vent loop.

The first reverse return system shows a system, which is

commonly used to minimize individual unit water flow balanc-

ing and is often referred to as “self balancing.” This riser ar-

rangement has a natural affinity to balance the flow to each unit

in the riser column. However, individual unit balancing may

still be required. This piping system is used on 2-pipe systems

only and has an individual return for each riser column.

The second reverse return system shows a system with a

common reverse return riser installed separately from the

individual unit riser columns. This riser arrangement allows for

more flexibility in individual unit riser sizing but has the same

general characteristics as the “reverse return” system described

above. It may also be a better fit for the particular structural and

architectural requirements of the building. This piping system

may also be used on 4-pipe systems.

Regardless of the system selected, optimum performance

can only be achieved through adjustment to the recommended

water flow at each individual unit (see Table 1 for individual

unit water flow requirements).

RISER MATERIAL, SIZING, AND INSULATION —

Some of the factors affecting riser application and sizing are

noise, tube erosion and economics. Water source heat pumps

maybe supplied with factory-installed risers; the riser material,

diameter, length and insulation thickness must be determined

for each unit based on its positioning within the building.

Figure 8 displays riser tube diameter sizes as a function of flow

(gpm), friction loss and water velocity. For maximum riser

velocity on pressure drop per 100 ft, refer to ASHRAE (Amer-

ican Society of Heating, Refrigeration, and Air Conditioning

Engineers) Fundamentals Handbook for Riser Sizing. Gener-

ally, riser copper type, size, length and insulation thickness are

determined by the location of the water source heat pump unit

in the building. Chilled water and hot water risers are available

in Type-M, Type-L copper, varying diameters from

3

/

4

to

2

1

/

2

in., and with either no insulation,

1

/

2

or

3

/

4

in. thick closed

cell foam insulation. Condensate risers are available in Type-M

copper, varying diameters from

3

/

4

to 1

1

/

4

in., and with no

insulation,

1

/

2

or

3

/

4

in. thick closed cell foam insulation. All

factory-supplied risers and riser extensions are insulated for the

full length of the riser, eliminating the need for field insulation.

Insulation is not required on loop water piping except where

the piping runs through unheated areas, outside the building or

when the loop water temperature is below the minimum

expected dew point of the pipe ambient conditions. Insulation

is required if loop water temperature drops below the dew

point (insulation is required for the ground loop applications in

most climates).

Riser sizing is generally based on the water flow require-

ments of each unit and the units on higher and lower floors that

tie into the same riser column depending on the piping system

chosen. Water piping is often designed at approximately 5 ft/s.

Keeping this in mind, risers can be reduced in size as the water

flow decreases from floor to floor. For low-rise buildings, riser

sizes can be of a single diameter.

The reduced material handling on site will often offset the

extra costs associated with the larger risers.

RISER EXPANSION — Generally, in medium to high-rise

buildings, allowances must be made for pipe expansion. In ap-

plications supplemented with factory (or field) supplied be-

tween the floor riser extensions, assemble and install exten-

sions before installing cabinet.

NOTE: Riser assemblies are designed to accommodate a

maximum of 1

1

/

8

in. expansion and contraction up to a total

movement of 2

1

/

4

inches. If the total calculated rise expansion

exceeds 2

1

/

4

in., expansion devices must be used (field

provided).

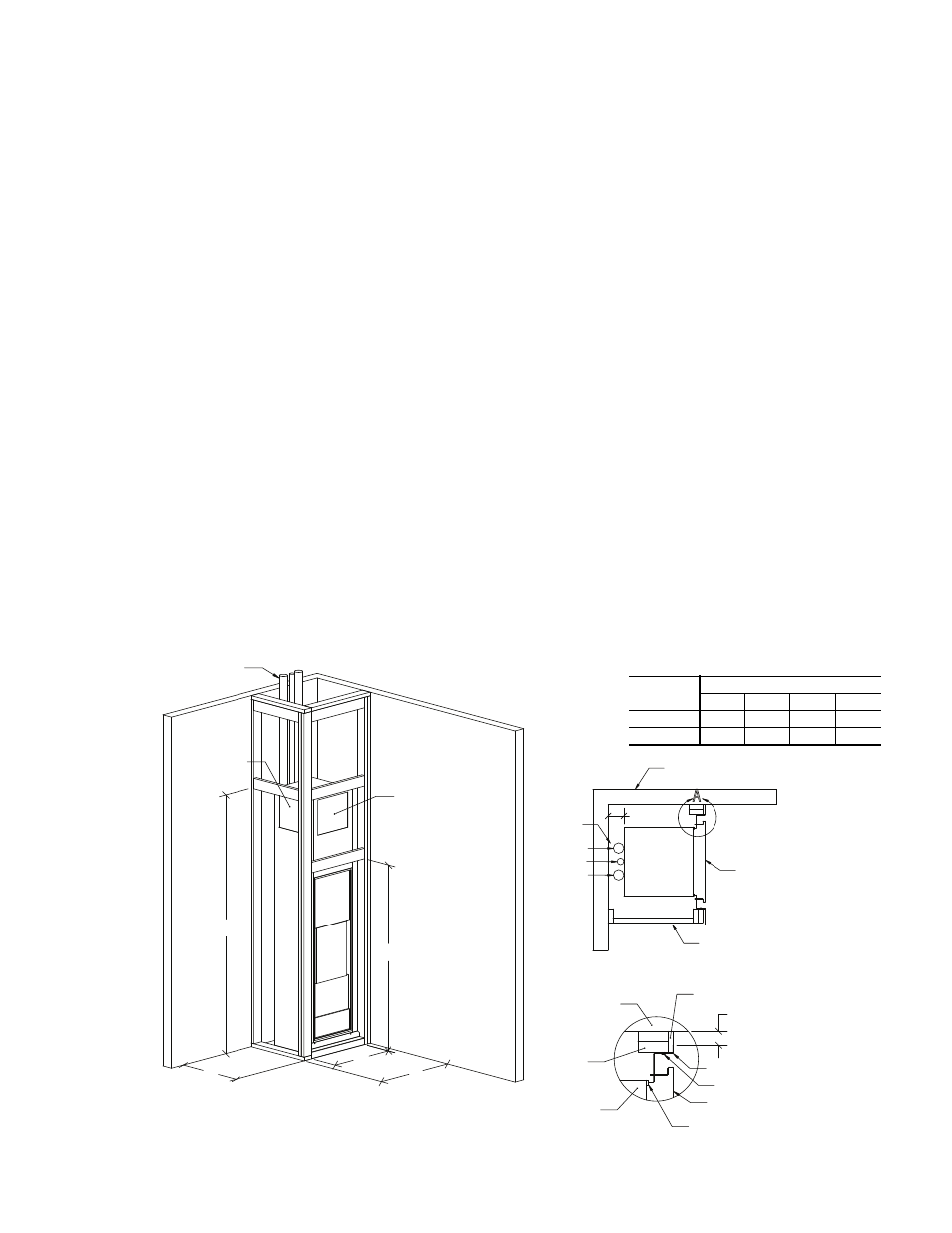

4-in. MIN

TOP VIEW

EXISTING WALL

RISERS

DRYWALL

RETURN PANEL

SUPPLY

RETURN

DRAIN

A

A

B

C

D

88.5 in.

SUPPLY OPENING

TO ABOVE FLOOR

SUPPLY

OPENING

DETAIL A

DRYWALL

EXISTING WALL

RETURN PANEL

FASTENERS BY OTHERS

FRAME

STUD

UNIT CABINET

GASKET

1 11/16 in. MIN

Fig. 6 — Framing Rough-In Detail

50VS UNIT

SIZE

DIMENSIONS (in.)

A

B

C

D

50VSA-VSH

24

5

/

8

30

11

/

16

24

5

/

8

63

11

/

16

50VSI-VSN

30

7

/

8

36

11

/

16

30

5

/

8

64

7

/

16

a50-8331.eps