System checkout, Field selectable inputs, Dip switch settings and operation – Carrier AQUAZONE 50VS User Manual

Page 18

18

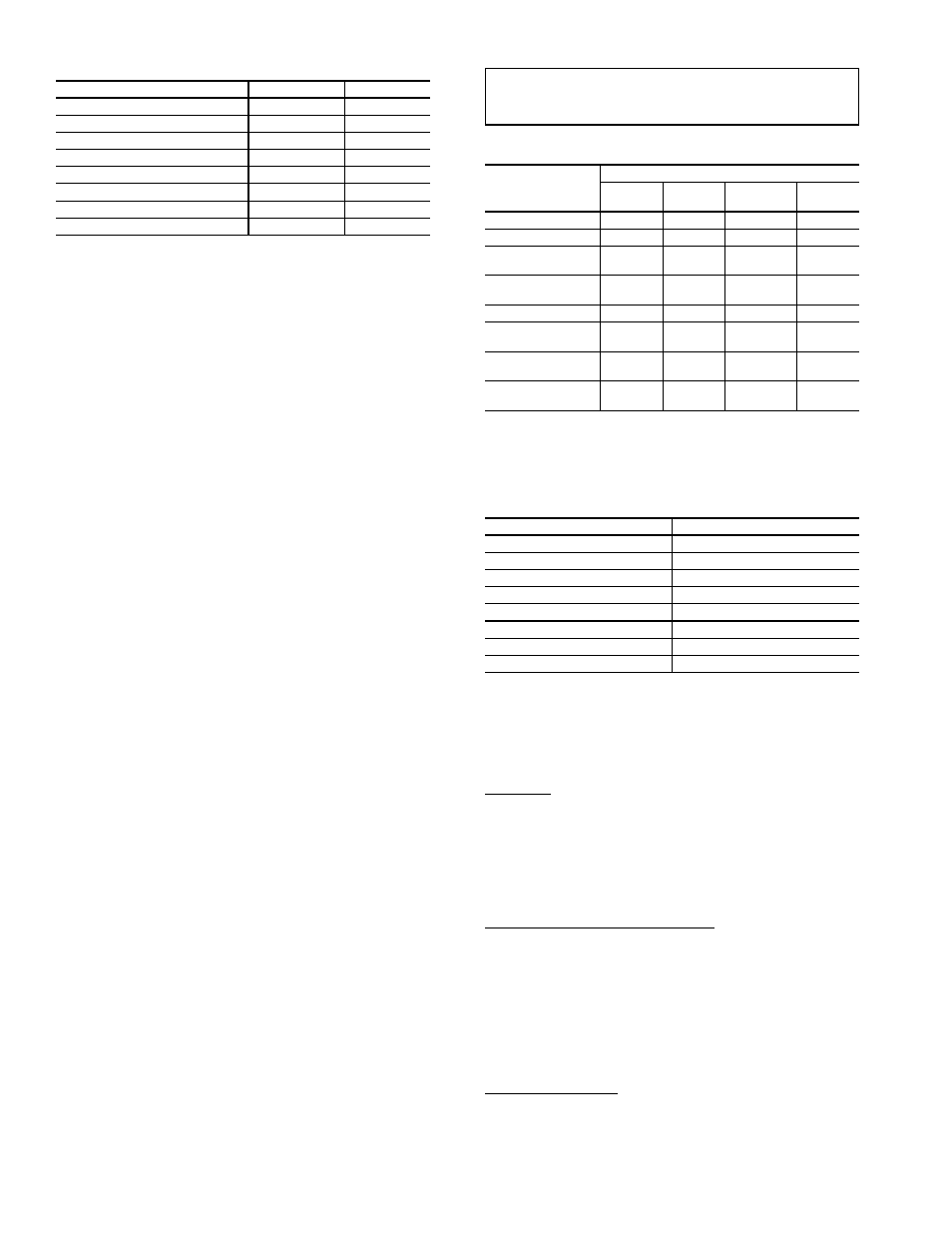

Table 9 — Limits of Operation

LEGEND

*Requires additional insulation when operating below the dew point.

4. Unit fan: Manually rotate fan to verify free rotation and

ensure that blower wheel is secured to the motor shaft. Be

sure to remove any shipping supports if needed. DO NOT

oil motors upon start-up. Fan motors are pre-oiled at the

factory. Check unit fan speed selection and compare to

design requirements.

5. Condensate line: Verify that condensate line is open and

properly pitched toward drain.

6. Water flow balancing: Record inlet and outlet water tem-

peratures for each heat pump upon start-up. This check

can eliminate nuisance trip outs and high velocity water

flow that could erode heat exchangers.

7. Unit controls: Verify that the microprocessor DIP (dual

in-line package) switches are set for proper operation and

system configuration.

System Checkout

1. System water temperature: Check water temperature for

proper range and also verify heating and cooling set

points for proper operation.

2. System pH: Check and adjust water pH if necessary to

maintain a level between 6 and 8.5. Proper pH promotes

longevity of hoses and fittings.

3. System flushing: Verify that all hoses are connected end

to end when flushing to ensure that debris bypasses the

unit heat exchanger, water valves and other components.

Water used in the system must be potable quality initially

and clean of dirt, piping slag, and strong chemical clean-

ing agents. Verify that all air is purged from the system.

Air in the system can cause poor operation or system

corrosion.

4. Cooling tower/boiler: Check equipment for proper set

points and operation.

5. Standby pumps: Verify that the standby pump is properly

installed and in operating condition.

6. System controls: Verify that system controls function and

operate in the proper sequence.

7. Low water temperature cutout: Verify that low water

temperature cutout controls are provided for the outdoor

portion of the loop. Otherwise, operating problems may

occur.

8. System control center: Verify that the control center and

alarm panel have appropriate set points and are operating

as designed.

FIELD SELECTABLE INPUTS

Jumpers and DIP switches on the control board are used to

customize unit operation and can be configured in the field. See

Tables 10 and 11 for heat pump and BacNet control board DIP

switch settings.

Table 10 — Heat Pump Control Board (PCB)

LEGEND

Table 11 — BacNet™ Control Board (PCB)

LEGEND

DIP Switch Settings and Operation

DIP SWITCH 1 (Test Mode = Off/Normal Mode = On)

Test Mode — Test mode is used to speed up the operation

sequence of the unit, therefore creating a more timely trouble-

shooting technique. All time delays are shorted by 10 times

with the exception of the high-pressure lockout which is

instantaneous regardless of which mode the switch is posi-

tioned. DIP switch 1 must be placed into the Normal mode to

resume proper operation of the unit.

DIP SWITCH 2 (FP 1 at 15 F = Off/FP 1 at 32 F = On)

Water Side Freeze Protection Setting — DIP switch 2 is used

to determine the loop freeze protection setting. Depending on

the brine concentration of the liquid source, the temperature

can be set at 15 F or 32 F. The switch MUST be set to the “On”

position if pure water is used as the source brine. This is nor-

mally the case in open loop systems. Set the DIP switch to the

“Off” position for closed loop systems that contain a brine con-

centration that allows liquid temperatures to fall to, or below,

15 F.

DIP SWITCH 3 (Tstat at Comm = off/tstat at 24-vac = On)

Thermostat Selection — DIP switch 3 is used to select the

type of thermostat that will be used to control the unit. A digi-

tal communicating thermostat can be purchased with the unit

that will allow all fault signals to be displayed on the

thermostat. This allows for efficient troubleshooting and does

not require that the technician access the electrical control box

Air Limits

Cooling (F)

Heating (F)

Ambient Air Maximum

50

50

Ambient Air Minimum

100

85

Rated Ambient Air

80.6

68

Rated Entering Air (db/wb)

80.6/66.2

68

Entering Air Maximum (db/wb)

100/83

80

Entering Water Minimum*

30

20

Entering Water (Normal)

50-110

30-70

Entering Water Maximum

120

90

db — Dry Bulb

wb — Wet Bulb

IMPORTANT: Jumpers and DIP switches should only

be clipped when power to control board has been turned

off.

DIP SWITCH

NUMBER

PROTOCOL

No

Network

BacNet

LonWorks

Modbus

(PC)

1 — Test/Normal

ON ON

ON

ON

2 — FP1 15 F/32 F

ON

ON

ON

ON

3 — Tstat Comm/

24-vac

ON or

OFF

OFF

OFF

OFF

4 — RV Cooling

Off/On

ON

ON

ON

ON

5 — Com2/Com1

ON

OFF

OFF

OFF

6 — Com2 Modbus

Address

OFF

OFF

OFF

OFF

7 — Com2 Modbus

Address

OFF

OFF

OFF

OFF

8 — Com2 Modbus

Address

OFF

OFF

OFF

OFF

DIP

— Dual In-Line Package

PC

— Personal Computer

PCB — Printed Circuit Board

DIP SWITCH NUMBER

POSITION OFF/ON

1

ON

2

OFF

3

OFF

4

OFF

5

OFF

6

OFF

7

OFF

8

OFF

DIP

— Dual In-Line Package

PCB — Printed Circuit Board