Carrier AQUAZONE 50VS User Manual

Page 20

20

f. Turn thermostat to “OFF” position. A hissing noise

indicates proper functioning of the reversing valve.

g. Allow 5 minutes between tests for pressure to

equalize before beginning heating test.

h. Adjust the thermostat to the lowest setting. Place

the thermostat mode switch in the “HEAT”

position.

i. Slowly raise the thermostat to a higher temperature

until the compressor activates.

j. Check for warm air delivery within a few minutes

after the unit has begun to operate.

k. Refer to Table 9. Check the temperature of both

entering and leaving water. If temperature is within

range, proceed with the test. If temperature is out-

side of the operating range, check refrigerant

pressures.

l. Check air temperature rise across the air coil when

compressor is operating. Air temperature rise

should be between 20 and 30 F.

m. Check for vibration, noise, and water leaks.

6. If unit fails to operate, perform troubleshooting analysis

(see troubleshooting section). If the check described fails

to reveal the problem and the unit still does not operate,

contact a trained service technician to ensure proper diag-

nosis and repair of the equipment.

7. When testing is complete, set system to maintain desired

comfort level.

NOTE: If performance during any mode appears abnormal

refer to the troubleshooting section of this manual. To obtain

maximum performance, the air coil should be cleaned before

start-up. Use a coil cleaner for use on indoor evaporator refrig-

eration equipment.

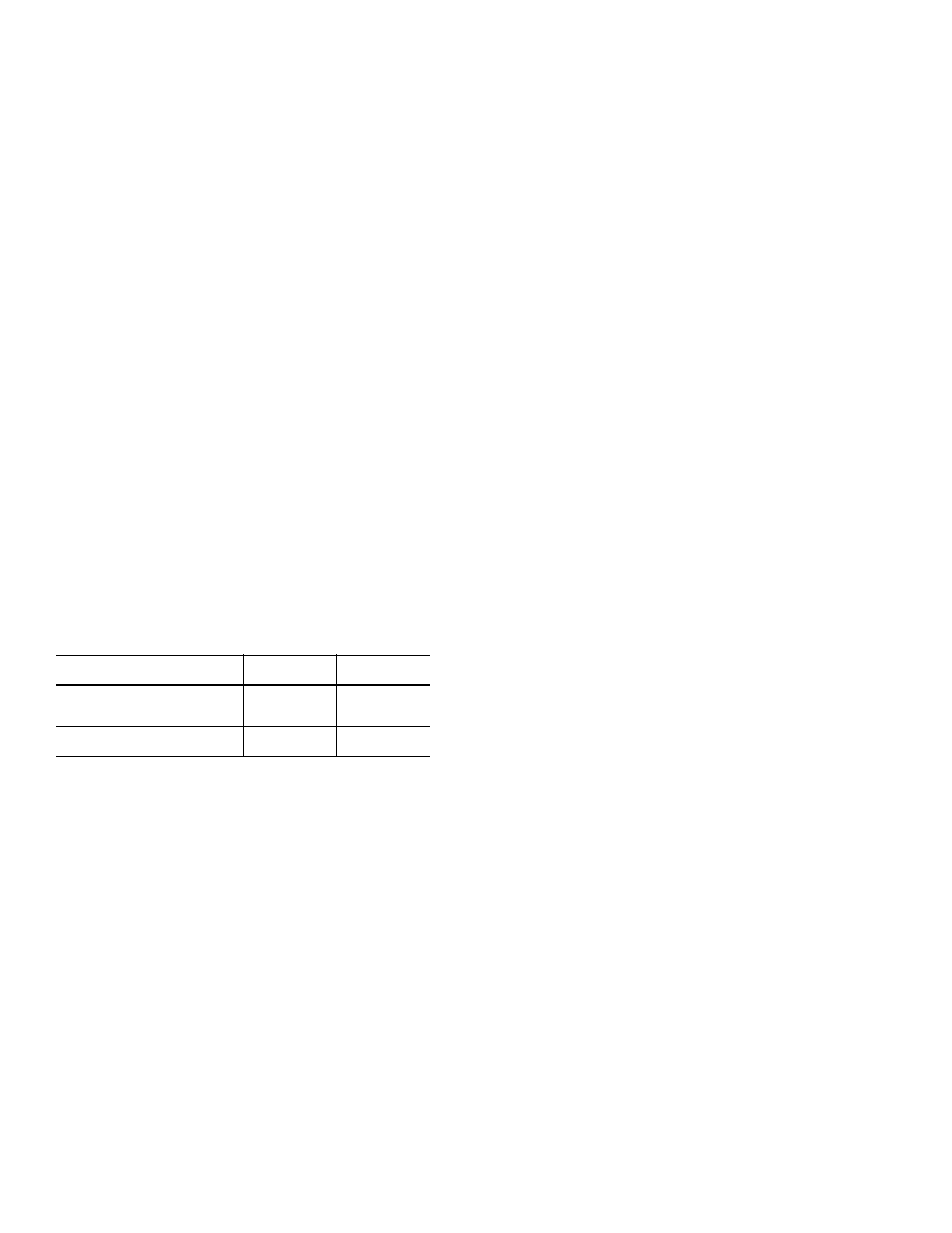

Table 12 — Temperature Change Through Heat

Exchanger

Operating Limits

ENVIRONMENT — Units are designed for indoor installa-

tion only. Never install units in areas subject to freezing or

where humidity levels could cause cabinet condensation (such

as unconditioned spaces subject to 100% outside air).

POWER SUPPLY — A voltage variation of 10% of name-

plate utilization voltage is acceptable.

STARTING CONDITIONS — Starting conditions vary de-

pending upon model number and are based upon the following:

• Conditions in Table 9 are not normal or continuous operat-

ing conditions. Minimum/maximum limits are start-up con-

ditions to bring the building space up to occupancy

temperatures. Units are not designed to operate under these

conditions on a regular basis.

• Voltage utilization range complies with ARI Standard 110.

• Determination of operating limits is dependent primarily

upon three factors:

a. Ambient temperature

b. Return air temperature

c. Water temperature

• When any one of these factors is at minimum or maximum

levels, the other two factors should be at normal levels to

ensure proper unit operation.

Extreme variations in temperature and humidity and/or cor-

rosive water or air will adversely affect unit performance, reli-

ability, and service life.

Lockout Mode —

If the microprocessor board is flashing

a system warning and the unit is locked out and not running,

the lockout can be cleared from the microprocessor by a mo-

mentary shutdown of incoming line voltage (208-vac or

230-vac). A lockout that still occurs after line voltage shut-

down means that the fault still exists and needs to be repaired.

HIGH-PRESSURE LOCKOUT (HP) — The high-pressure

lockout will occur if the discharge pressure of the compressor

exceeds 600 psi. The lockout is immediate and has no delay

from the time the high-pressure switch opens to the lockout.

Upon lockout the compressor will be deenergized immediately.

The blower will be deenergized 15 seconds after the compres-

sor is deenergized.

LOW-PRESSURE LOCKOUT (LP) — The low-pressure

lockout will occur if the suction pressure falls below 40 psi for

30 continuous seconds. The compressor will then be de-

energized and the blower will deenergize 15 seconds after the

compressor is deenergized.

FREEZE PROTECTION 1 LOCKOUT — The freeze pro-

tection 1 lockout will occur if the liquid line temperature falls

below the set point (15 F or 30 F) for 30 continuous seconds.

See DIP switch 2 description in the DIP Switch Settings and

Operation section. The compressor will then be deenergized

and the blower will deenergize 15 seconds after the compressor

is deenergized.

FREEZE PROTECTION 2 LOCKOUT — The freeze pro-

tection 1 lockout will occur if the air coil temperature falls be-

low the set point 32 F for 30 continuous seconds. See DIP

switch 2. The compressor will then be deenergized and the

blower will deenergize 15 seconds after the compressor is

deenergized.

CONDENSATE OVERFLOW 1 LOCKOUT (CO1) —

The unit contains one condensate overflow sensor located in

the chassis drain pan below the air coil. A condensate lockout

will occur if the sensor senses condensate for 30 continuous

seconds. The compressor will then be deenergized and the

blower will deenergize 15 seconds after the compressor is

deenergized.

OVER/UNDER VOLTAGE PROTECTION — If the unit

control voltage is less than 18-vac or greater than 30-vac the

unit will shut down all inputs immediately. Once the voltage

has reached acceptable levels the unit microprocessor will

power “On” automatically and resume previous operation.

LEAVING WATER TEMPERATURE SENSOR FAIL-

URE (LWT) — If the leaving water temperature thermistor

fails it will not affect the operation of the unit. This sensor is for

monitoring purposes only.

DISCHARGE AIR TEMPERATURE SENSOR FAILURE

(DAT) — If the discharge temperature thermistor fails it will

not affect the operation of the unit. This sensor is for monitor-

ing purposes only.

FREEZE PROTECTION 1 TEMPERATURE SENSOR

FAILURE (FP1) — If the freeze protection 1 thermistor fails

for 30 continuous seconds an FP1 lockout will occur. The

compressor will then be deenergized and the blower will deen-

ergize 15 seconds after the compressor is deenergized. The sen-

sor must be replaced if this lockout occurs.

FREEZE PROTECTION 2 TEMPERATURE SENSOR

FAILURE (FP2) — If the freeze protection 2 thermistor fails

for 30 continuous seconds an FP2 lockout will occur. The

compressor will then be deenergized and the blower will

deenergize 15 seconds after the compressor is deenergized. The

sensor must be replaced if this lockout occurs.

WATER FLOW GPM

RISE IN

COOLING (°F)

DROP IN

HEATING (°F)

For Closed Loop: Ground

Source or Closed Loop

Systems at 3 gpm per ton

9-12

4-8

For Open Loop: Ground Water

Systems at 1.5 gpm per ton

20-26

10-17