Control panel operating procedures – AERCO BMK 3.0 LN Dual Fuel June 2010 User Manual

Page 31

CONTROL PANEL OPERATING PROCEDURES

1. The

DEMAND

LED status indicator will light.

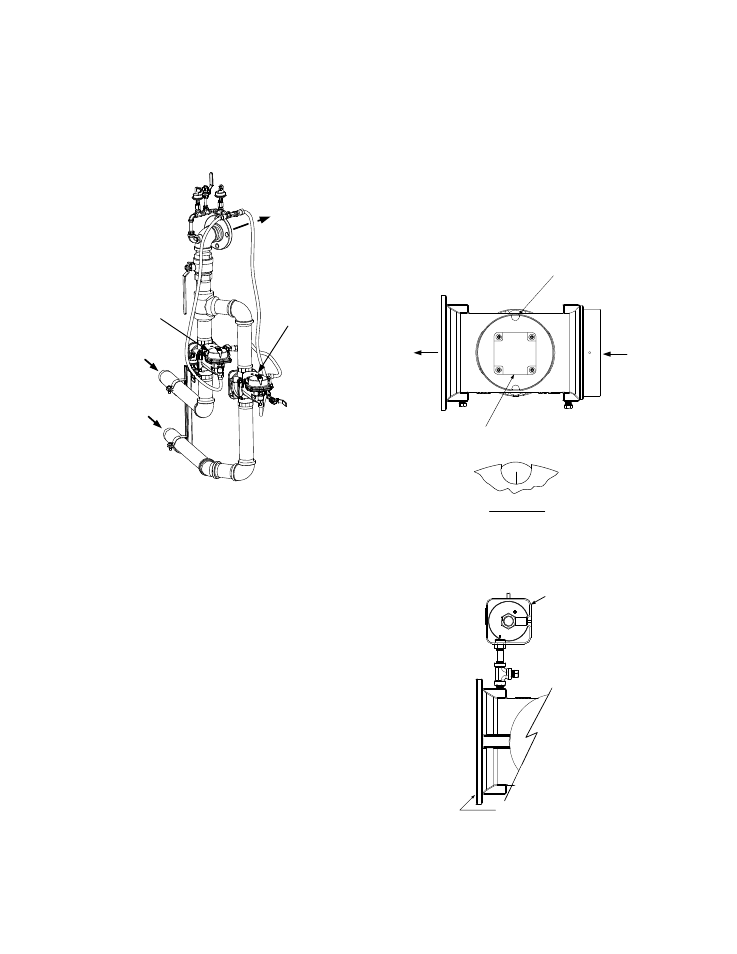

2. The unit checks to ensure that the Proof of

Closure (POC) switch in the downstream

Safety Shut-Off Valve (SSOV) is closed.

See Figure 3-3 for SSOV locations.

PROPANE

SSOV

NATURAL

GAS SSOV

PROPANE

INLET

NATURAL

GAS INLET

TO

AIR/FUEL

VALVE

Figure 3-3.

SSOV Locations

3. With all required safety device switches

closed, a purge cycle will be initiated and the

following events will occur:

(a) The Blower relay energizes and turns

on blower.

(b) The Air/Fuel Valve rotates to the full-

open purge position and closes purge

position switch. The dial on the Air/Fuel

Valve (Figure 3-4) will read 100 to

indicate that it is full-open (100%).

(c) The VALVE POSITION bargraph will

show 100%.

4. Next, the blower proof switch on the Air/Fuel

Valve (Figure 3-5) closes. The display will

show Purging and indicate the elapsed time

of the purge cycle in seconds. The normal

(default) time for the purge cycle is 7

seconds.

5. Upon completion of the purge cycle, the

Control Box initiates an ignition cycle and

the following events occur:

(a) The Air/Fuel Valve rotates to the low-

fire ignition position and closes the

ignition switch. The dial on the Air/Fuel

Valve (Figure 3-6) will read between 25

and 35 to indicate that the valve is in

the low-fire position.

(b) The igniter relay is activated and

provides ignition spark.

(c) The gas Safety Shut-Off Valve (SSOV)

is energized (opened) allowing gas to

flow into the Air/Fuel Valve.

100

DETAIL “A”

TO

B

LOWE

R

AI

R

IN

DIAL

(DETAIL “A”)

STEPPER

MOTOR

Figure 3-4.

Air/Fuel Valve In Purge Position

BLOWER

PROOF

SWITCH

AIR/FUEL

VALVE OUTLET

TO BLOWER

Figure 3-5.

Blower Proof Switch

3-9