4 low water level fault test, 5 water temperature fault test, 6 interlock tests – AERCO BMK 2.0 LN Nat. Gas User Manual

Page 44: Safety device testing

SAFETY DEVICE TESTING

6-2

6.4 LOW WATER LEVEL FAULT TEST

1. Place the ON/OFF switch in the OFF

position.

2. Close shut-off valves in the supply and

return piping to the unit.

3. Slowly open the drain valve on the rear of

the unit. If it is necessary to vent the unit to

aid in draining, the unit’s relief valve may be

opened.

4. Drain the unit until the LOW WATER LEVEL

fault message is displayed and the FAULT

LED flashes.

5. Place the unit in the Manual Mode and raise

the firing rate above 25%.

6. Set

the

ON/OFF switch to ON. The READY

light should remain off and the unit should

not start. If the unit does start, shut the unit

off immediately and refer fault to qualified

service personnel.

7. Close the drain and pressure relief valve

used in draining the unit.

8. Open the water shut-off valve in the return

piping to the unit to fill the shell.

9. Open the water shut-off valve in the supply

piping to the unit.

10. After the shell is full, press the LOW

WATER LEVEL RESET button to reset the

low water cutoff. Press the CLEAR switch to

reset the FAULT LED and clear the

displayed error message.

11. Set the ON/OFF switch to the ON position.

The unit is now ready for operation.

6.5 WATER TEMPERATURE FAULT

TEST

1. In the normal operating mode, allow the unit

to stabilize at its setpoint.

2. Lower the adjustable temperature limit

switch setting to match the displayed

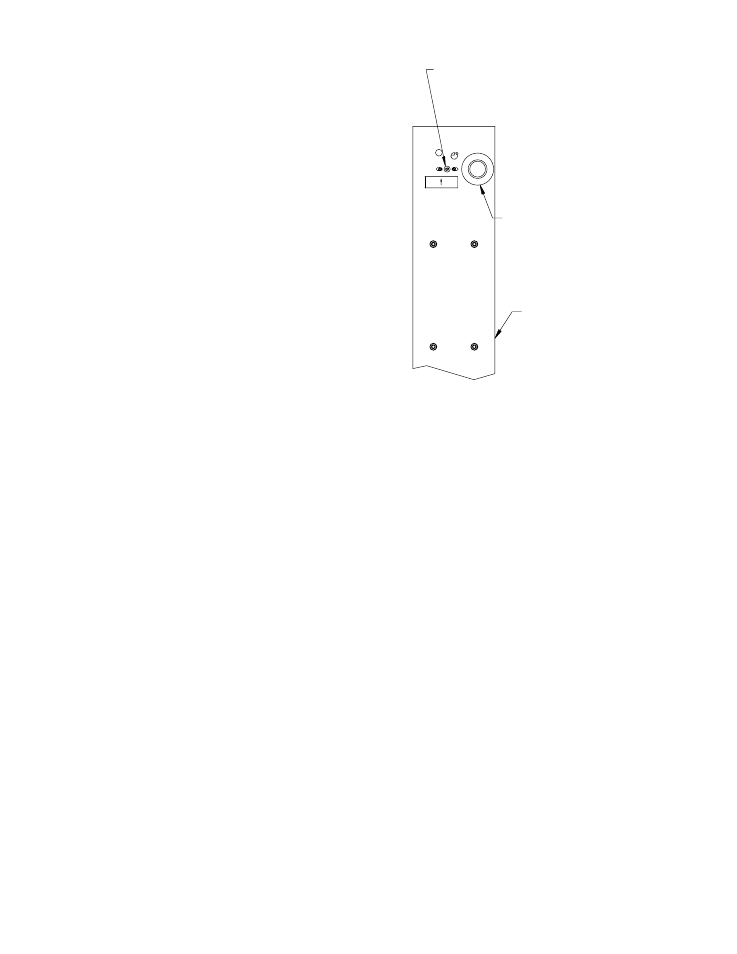

OUTLET TEMPERATURE. (See Fig. 6.2)

RESET BUTTON FOR MANUAL

RESET TEMPERATURE LIMIT

SWITCH

HIGH LIMIT

ADJUSTABLE

TEMPERATURE

LIMIT SWITCH

MOUNTING PLATE

ON SHELL

Figure 6.2

Temperature Limit Switch Setting

3. Once the adjustable limit switch setting is

approximately at, or just below, the actual

outlet water temperature, the unit should

shut down. The FAULT LED should be

flashing and the message HIGH WATER

TEMP SWITCH OPEN should be displayed.

The unit should not start.

4. Reset the adjustable temperature limit

switch setting to its prior setting.

5. The unit should start once the adjustable

temperature limit switch setting is above the

actual outlet water temperature.

6.6 INTERLOCK TESTS

The unit is equipped with two interlock circuits

called the Remote Interlock and Delayed

Interlock. Terminal connections for these circuits

are located in the I/O Box and are labeled

REMOTE INTL’K IN and DELAYED INTL’K IN.

These circuits can shut down the unit in the

event that an interlock is opened. These

interlocks are shipped from the factory jumpered

(closed). However, each of these interlocks may

be utilized in the field as a remote stop and start,

an emergency cut-off, or to prove that a device

such as a pump gas booster, or louver is

operational.