Chapter 6 - safety device testing procedures, 1 testing of safety devices, 2 low gas pressure fault test – AERCO BMK 2.0 LN Nat. Gas User Manual

Page 43: 3 high gas pressure test, Safety device testing

SAFETY DEVICE TESTING

6-1

Chapter 6 - SAFETY DEVICE TESTING PROCEDURES

6.1 TESTING OF SAFETY DEVICES

Periodic safety device testing is required to

ensure that the control system and safety

devices are operating as designed. The AERCO

control system comprehensively monitors all

combustion related safety devices before, during

and after the start sequence. The following tests

have been chosen to ensure that the system will

either not start or will shut-down as intended.

Operating and safety controls should be tested

on a regular basis or after a safety device has

been serviced or replaced. All testing must

conform to local codes such as ASME CSD-1.

NOTE:

MANUAL and AUTO modes are required to

perform the following tests. For a complete

explanation of these modes, see Chapter 3.

NOTE:

It will be necessary to remove the sheet

metal covers from the unit to perform the

following tests.

WARNING!

ELECTRICAL VOLTAGES IN THIS

SYSTEM MAY INCLUDE 460, 220, 120

AND 24 VOLTS AC. POWER MUST BE

REMOVED PRIOR TO PERFORMING

WIRE REMOVAL OR OTHER TESTING

PROCEDURES THAT CAN RESULT IN

ELECTRICAL SHOCK.

6.2 LOW GAS PRESSURE FAULT TEST

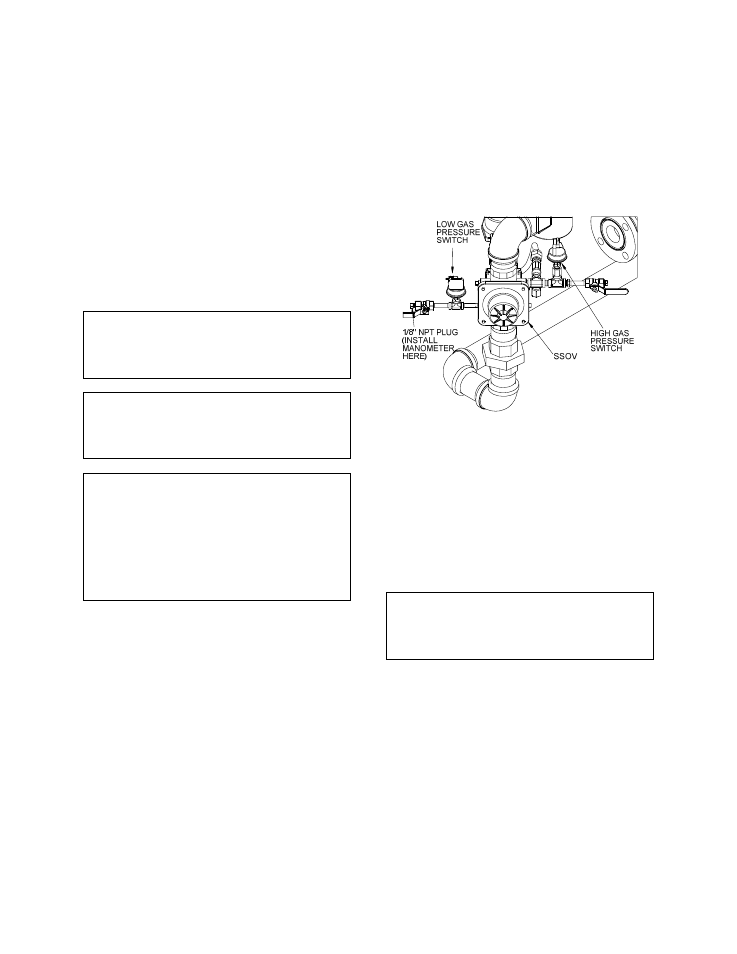

1. Referring to Figure 6.1, ensure that the 1/8"

NPT ball valve upstream of the SSOV is

closed (located at low gas pressure switch).

2. Remove the 1/8" plug from the ball valve,

upstream of the safety shutoff valve (SSOV).

3. Install a 0-16" W.C. manometer or W.C.

gauge where the 1/8" plug was removed.

4. Slowly open the 1/8" ball valve upstream of

the SSOV.

5. Place the unit in Manual Mode and fire the

unit at a firing rate between 25% and 30%.

6. While the unit is firing, slowly close the Man-

ual gas shut-off valve located immediately

outside the boiler. The unit should shut down

on a LOW GAS PRESSURE fault message

at 4.4” W.C. For Benchmark 2.0 Low NOx

boilers configured for De-Rated capacity

(see para. 2.4.1), the unit should shut down

on a LOW GAS PRESSURE fault message

at 3.6” W.C.

Figure 6.1

1/8” Pipe Plug Position for Manometer

Installation & Low Gas Pressure Testing

7. Fully open the manual gas shut-off valve and

press the CLEAR button on the Control Box.

8. The unit should restart.

9. Remove manometer and replace 1/8”NPT

plug.

NOTE:

After faulting the unit, the fault message will

be displayed and the fault indicator light will

flash until the CLEAR button is pressed.

6.3 HIGH GAS PRESSURE TEST

1. Start the unit in manual mode and fire

between 25% and 30%.

2. Remove either wire # 150 or wire #151 from

the high gas pressure switch. See Fig. 6.1.

3. The unit should shut down on a HIGH GAS

PRESSURE FAULT.

4. Reconnect the wire previously removed from

the high gas pressure switch and depress

the CLEAR button.

5. The unit should restart.