Timing charts, Warnings and remedies, External dimensions – KEYENCE SJ-F5000 Series User Manual

Page 4: Specifications, Changing the electrode probes, Cleaning the rear air filter, Changing the fuse, Main body (with stand attached), Static eliminator unit main body, Warranties and disclaimers

4

Copyright (c) 2010 KEYENCE CORPORATION. All rights reserved.

11352E 1060-1 96M11352

Printed in Japan

Changing the electrode probes

Replace the electrode probe if the static elimination capability fails to recover after you clean the

electrode probe, or if the red alarm for the condition/ion level indicator flashes (ON OFF ON OFF)

frequently. Prepare the optional electrode unit for replacement (SJ-F2000 series: OP-87153,

SJ-F5000 series: OP-87154).

To mount an electrode probe, perform the cleaning procedure in the reverse order. Follow the

steps described in

"Start/stop static elimination" (page 3) and resume static elimination.

Cleaning the rear air filter

If the airflow level for the static elimination blower decreases, or if the air filter becomes dirty, take

out the rear cover and use cleaner or a similar agent to remove the dust from the inside filter.

Changing the fuse

When the fuse blows, replace the fuse in the fuse holder located under the AC inlet. Be sure to use a

fuse rated 250V, 1.6A, Time lag. (Recommended fuse: ET series manufactured by SOC Corporation)

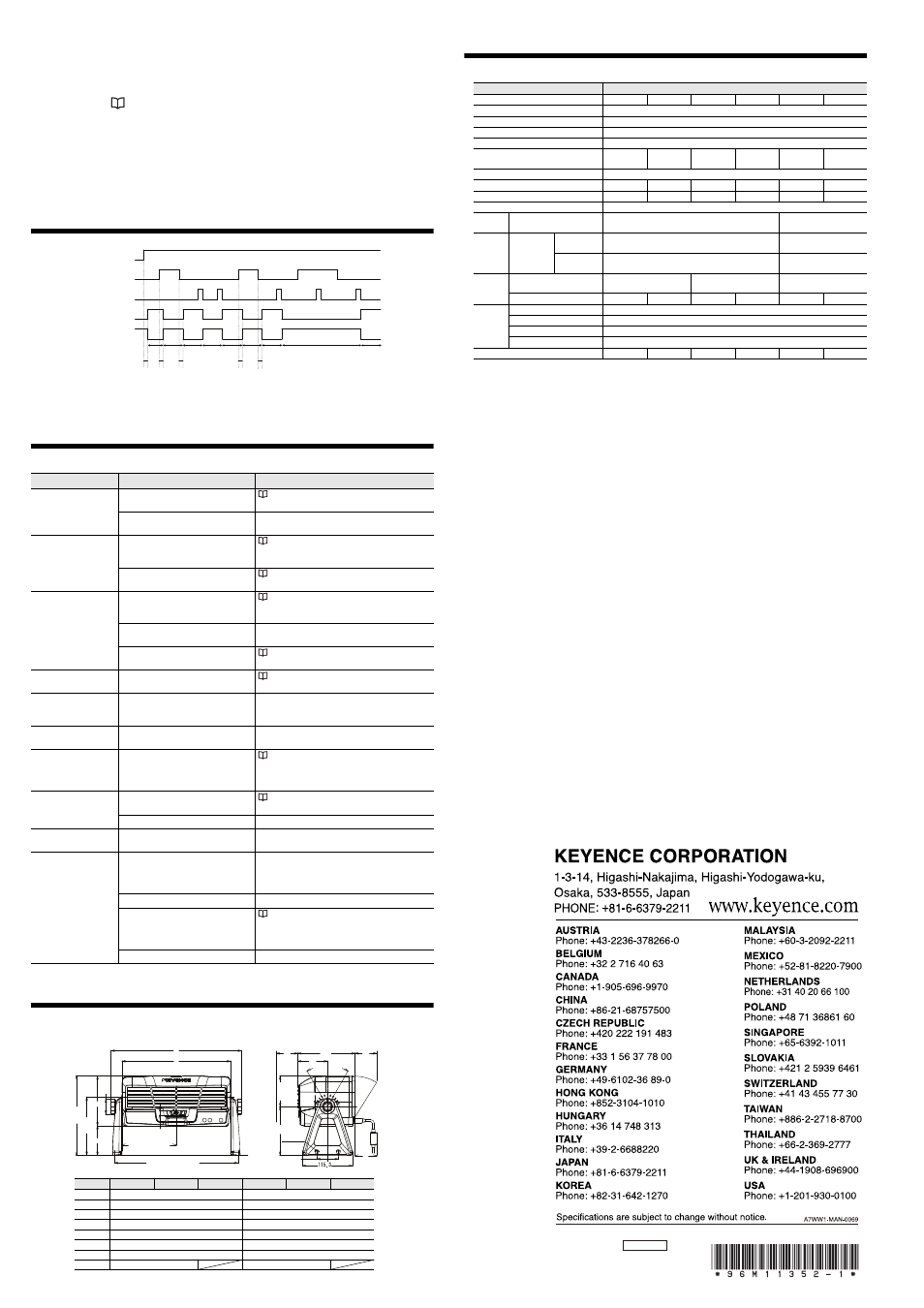

Timing Charts

* The static elimination interruption input (input terminal) and the alarm output (output terminal)

are only for SJ-F2010/5010).

Warnings and Remedies

Refer to the following list for troubleshooting and remedies before sending out the unit for repairs.

External Dimensions

Main body (with stand attached)

Specifications

Static Eliminator Unit main body

*1 Measured at a distance of 300 mm from the front side of the fan

*2 Measured at a distance of 300 mm from the front side of the fan, using the maximum air flow rate

WARRANTIES AND DISCLAIMERS:

(1) KEYENCE warrants the Products to be free of defects in materials and workmanship for a

period of one (1) year from the date of shipment. If any models or samples were shown to

Buyer, such models or samples were used merely to illustrate the general type and quality of

the Products and not to represent that the Products would necessarily conform to said models

or samples. Any Products found to be defective must be shipped to KEYENCE with all

shipping costs paid by Buyer or offered to KEYENCE for inspection and examination.

Upon examination by KEYENCE, KEYENCE, at its sole option, will refund the purchase price

of, or repair or replace at no charge any Products found to be defective.

This warranty does not apply to any defects resulting from any action of Buyer, including but

not limited to improper installation, improper interfacing, improper repair, unauthorized

modification, misapplication and mishandling, such as exposure to excessive current, heat,

coldness, moisture, vibration or outdoors air. Components which wear are not warranted.

(2) KEYENCE is pleased to offer suggestions on the use of its various Products. They are only

suggestions, and it is Buyer's responsibility to ascertain the fitness of the Products for Buyer’s

intended use. KEYENCE will not be responsible for any damages that may result from the use

of the Products.

(3) The Products and any samples ("Products/Samples") supplied to Buyer are not to be used

internally in humans, for human transportation, as safety devices or fail-safe systems, unless their

written specifications state otherwise.

Should any Products/Samples be used in such a manner or misused in any way, KEYENCE

assumes no responsibility, and additionally Buyer will indemnify KEYENCE and hold KEYENCE

harmless from any liability or damage whatsoever arising out of any misuse of the Products/

Samples.

(4) OTHER THAN AS STATED HEREIN, THE PRODUCTS/SAMPLES ARE PROVIDED WITH NO

OTHER WARRANTIES WHATSOEVER. ALL EXPRESS, IMPLIED, AND STATUTORY

WARRANTIES, INCLUDING, WITHOUT LIMITATION, THE WARRANTIES OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, AND NON-INFRINGEMENT

OF PROPRIETARY RIGHTS, ARE EXPRESSLY DISCLAIMED.

IN NO EVENT SHALL KEYENCE AND ITS AFFILIATED ENTITIES BE LIABLE TO ANY

PERSON OR ENTITY FOR ANY DIRECT, INDIRECT, INCIDENTAL, PUNITIVE, SPECIAL OR

CONSEQUENTIAL DAMAGES (INCLUDING, WITHOUT LIMITATION, ANY DAMAGES

RESULTING FROM LOSS OF USE, BUSINESS INTERRUPTION, LOSS OF INFORMATION,

LOSS OR INACCURACY OF DATA, LOSS OF PROFITS, LOSS OF SAVINGS, THE COST OF

PROCUREMENT OF SUBSTITUTED GOODS, SERVICES OR TECHNOLOGIES, OR FOR ANY

MATTER ARISING OUT OF OR IN CONNECTION WITH THE USE OR INABILITY TO USE THE

PRODUCTS, EVEN IF KEYENCE OR ONE OF ITS AFFILIATED ENTITIES WAS ADVISED OF A

POSSIBLE THIRD PARTY’S CLAIM FOR DAMAGES OR ANY OTHER CLAIM AGAINST

BUYER. In some jurisdictions, some of the foregoing warranty disclaimers or damage

limitations may not apply.

BUYER'S TRANSFER OBLIGATIONS:

If the Products/Samples purchased by Buyer are to be resold or delivered to a third party, Buyer

must provide such third party with a copy of this document, all specifications, manuals, catalogs,

leaflets and written information provided to Buyer pertaining to the Products/Samples.

Problem

Inspection

Remedy

Neither the indicator

nor the pilot lamp turns

ON.

Check that the power supply cable is

connected correctly.

Follow the steps in "Connecting to the power

supply" (page 2) to correctly connect the cable.

Check that the power supply is within

the rated range.

Use power supply within the rated range.

No static elimination is

performed.

Check that the electrode probes are

not worn out or dirty.

Follow the steps in "Maintenance of Electrode

Probes" (page 3) to perform maintenance or

replace electrode probes.

Check that static elimination is not

interrupted.

Follow the steps in "Operation and Function"

(page 3) to start static elimination.

Ion level (ION LEVEL)

alarm is illuminated and

output.

Check that the electrode probes are

not worn out or dirty.

Follow the steps in "Maintenance of Electrode

Probes" (page 3) to perform maintenance or

replace electrode probes.

Check that there is no conductive object

within 50 mm of the electrode probes.

Make sure there are no electrically conductive objects

within 50 mm of the front of the Static Eliminator Unit.

Check that the wiring is correct.

Follow the steps in "Connecting the grounding cable"

(page 2) to correctly connect the grounding cable.

The power is ON but

the fan does not rotate.

Check that static elimination has not

been interrupted.

Follow the steps in "Operation and Function"

(page 3) to start static elimination.

The condition (COND)

alarm is illuminated and

output.

Check that there is no conductive

object or another Static Eliminator Unit

close to the SJ-F2000/5000 Series.

Keep the SJ-F2000/5000 Series away from the

conductive object or the Static Eliminator Unit.

Control output is not

output correctly.

Check that the cable is wired correctly.

Check the output circuit and make sure that the

wiring is correct.

Static elimination

interrupt input is not

input properly.

Check that the cable is wired correctly.

Verify the input circuit and the wiring and

connect correctly according to "Input/output

circuit and the wiring method (SJ-F2010/5010

only)" (page 2).

There is little airflow.

Check that the airflow setting is not

too low.

Follow the steps in "Control the airflow" (page

3) to verify the settings.

Check that the rear filter is not clogged.

Remove the dust and contaminant clogged in the filter.

The three middle

indicators flash.

Check that the front cover has not

been removed.

Correctly mount the front cover, and then press and

hold the START/STOP button for approx. 2 seconds.

All indicators flash.

Abnormal discharge from the tip of

the electrode probe

Turn off the power and perform maintenance on the

electrode probe. If the alarm persists even after you

perform maintenance, remove any conductive

objects that may be near the Static Eliminator Unit.

Ground cable is not connected

Verify that the ground cable is actually connected.

Abnormal value for the internal

memory

Follow the steps described in "Initialization"

(page 3) and initialize the SJ-F2000/5000 Series.

If the alarm persists even after the initialization,

contact the nearest KEYENCE office.

Fan is damaged

Contact the nearest KEYENCE office.

Item

SJ-F2500

SJ-F2000

SJ-F2010

SJ-F5500

SJ-F5000

SJ-F5010

A

115

135

B

68.5

48.5

C

35

45

D

302.9

638.8

E

252

582

F

126

153.7/428.3

G

287

617

H

50

65.5

Power supply

Static elimination

interruption input

(Input terminal)

Static elimination

interruption input

(START/STOP button)

Ion generation

status

Alarm output

(Output terminal)

Normally

ON

Normally

OFF

Normally

ON

Forced

OFF

Normally

ON

Normally

OFF

Normally

ON

Forced OFF

Normally

ON

150ms 150ms

150ms 150ms

MAX

150ms

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

D

E

F (Lever center)

G (

φ4.5 hole pitch)

183.5

135.5

A

B

φC

Removable

front cover

50

133

50

69

Rotatable

360 degrees

(Cable projection

distance)

50 (

φ4.5 hole pitch)

φ4.5 hole × 4

Removable

filter

10.6

113

(70.5)

H

Item

Specifications

Model

SJ-F2500

SJ-F2000

SJ-F5500

SJ-F5000

SJ-F2010

SJ-F5010

Voltage application method

Pulse AC method

Applied voltage

±7000 V

Ion balance control method

I.C.C.

Ion balance

*1

±5 V

Static elimination time

*2

About

0.6 sec

About

1.0 sec

About

0.6 sec

About

1.0 sec

About

1.0 sec

About

1.0 sec

Operating distance

More than 50 mm

Maximum air speed

*1

5.7 m/s

3.5 m/s

5.7 m/s

3.5 m/s

3.5 m/s

3.5 m/s

Maximum air flow rate

4.0 m

3

/min 2.5 m

3

/min 10.0 m

3

/min 6.2 m

3

/min 2.5 m

3

/min 6.2 m

3

/min

Ozone concentration

Less than 0.005 ppm

Control

input

Static elimination

interruption input

-

DC24 V input

Control

output

Alarm/Ion

level alarm/

Condition

alarm

NPN open

collector

-

100 mA (Less than 40 V)

(Residual voltage 1 V or less)

PNP open

collector

-

100 mA (24 V ±10%)

(Residual voltage 3 V or less)

Rating

Power supply

DC24 V ±10%

AC100 - 240 V

(50/60 Hz)

DC24 V ±10%

Current consumption

1.2 A

0.9 A

90 VA

65 VA

1.0 A

1.9 A

Environ

ment

Ambient temperature

0°C - 50°C

Relative humidity

35% - 65%

Overvoltage category

II

Pollution degree

2

Weight

About 2 kg About 2 kg About 5 kg About 5 kg About 2 kg About 4 kg