Calibration, Operation calibration – Checkline MLT User Manual

Page 14

30

Operation

Calibration

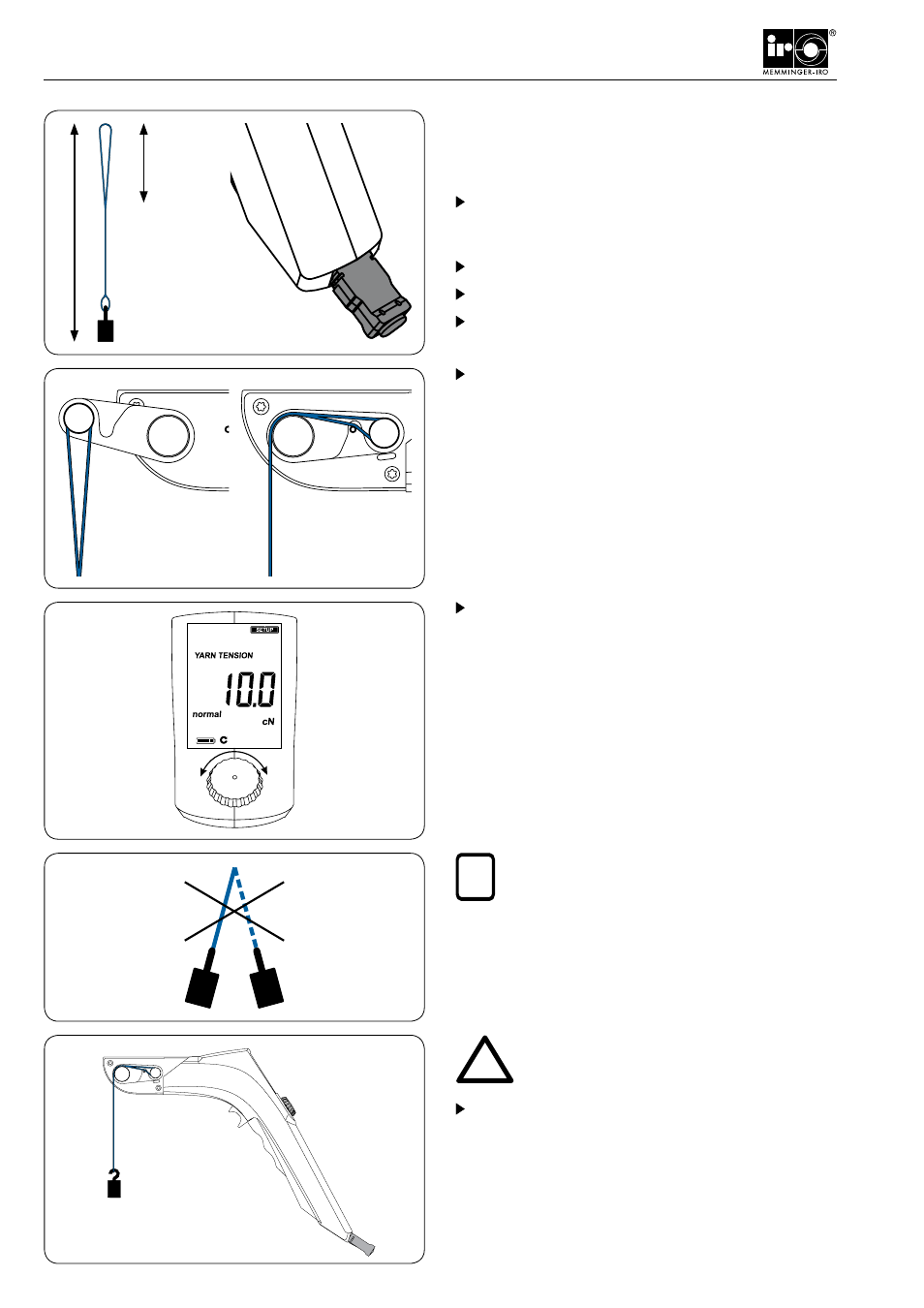

The calibration set is used to check the correct yarn

tension and to correct it if necessary.

For calibration purposes take the thread and form

a loop on each side. Attach the weight at the lower

loop.

The device is switched off.

Insert the calibration plug in the MLT WESCO.

Switch on the MLT WESCO and select YARN TEN-

SION.

Place the upper loop over the roller of the swivel arm.

Trigger the swivel arm release handle and keep it

pressed.

If the MLT WESCO does not show 10.0 cN the value

has to be corrected by turning the rotary knob.

ATTENTION!

In order to get an exact calibration the pro-

cedure has to be repeated several times.

To store the values unplug the calibration plug and

switch off the MLT WESCO.

!

ca. 30 cm

ca. 8 cm

NOTE!

The weight is not allowed to swing during

calibration.

i

- CDT-1000HD (6 pages)

- CDT-2000HD (9 pages)

- DT-105A (7 pages)

- DT-205LR (7 pages)

- PLT-5000 (7 pages)

- HTM (10 pages)

- YSL-2000HD (9 pages)

- DLM-107A (2 pages)

- A2105 (4 pages)

- DT-5TG (8 pages)

- MT2013 (2 pages)

- DT-209X (68 pages)

- WT3-200 (29 pages)

- WTT-110 (11 pages)

- WTT-110 (2 pages)

- WTTM-GEN1 (11 pages)

- TT-QC (10 pages)

- TT-QCM (16 pages)

- MTM (14 pages)

- ILTT (9 pages)

- TT02 (28 pages)

- TT Series (6 pages)

- DI-1M (6 pages)

- DIS-IP (6 pages)

- R55 (18 pages)

- TT05 (26 pages)

- CAP-TNP (10 pages)

- TSTM (9 pages)

- ETW (11 pages)

- HTG2 (8 pages)

- AD-100 (10 pages)

- DD-100 (3 pages)

- HP Series (6 pages)

- HPSA-R (5 pages)

- EMS4 (27 pages)

- MKM (5 pages)

- MST (24 pages)

- DT-5TS (20 pages)

- DIW (6 pages)

- DID-4 (6 pages)

- DIS-RL (6 pages)

- DSD-4 (4 pages)

- MGT (2 pages)

- CAP-TT01 (28 pages)