1 specifications, Pin d-sub connector) – Checkline MST User Manual

Page 6

6

Guide Rollers:

Calibration:

Acc. to SCHMIDT factory procedure with 0.2 mm Ø PA monofil

Tension Range:

1 - 500 cN

Accuracy:

± 1% FS* ± 1 digit (typically ± 0.5% FS*)

Overrange:

10% FS*, without accuracy guarantee

Overload Protection:

200% FS*

Measuring Principle:

Strain gauge bridge

Meas. Roller Deflection: max. 0.5 mm

Signal Processing:

Digital, 12 bit A/D converter

Damping:

Adjustable electronically (averaging)

Meas. Frequency:

Approx. 5 kHz internally

Display Update Rate:

2x per sec.

Display:

3-digit LCD, 11 mm high

Memory:

Average, last value, maximum, minimum, MAX

PEAK

, MIN

PEAK

Temperature Coefficient: Gain: less than ± 0.01% FS*/°C

Output Signal

Analog:

0 - 2 V DC (linearized), R

load

> 1 kW ± approx. 1%

Converter frequency 30 Hz

Digital:

RS-232 (9600, 8, N, 1)

Temperature Range:

10 - 45° C

Air Humidity:

85% RH, max.

Auto Power Off:

Automatically after approx. 3 min. of non-use

Power Supply:

9 V E block, e.g. long life 9 V lithium

AC adapter 12 V, 500 mA

Housing Material:

Aluminium profile with plastic outer casing (PVC)

Housing Dimensions

(incl. clamping device):

215 mm x 100 (140) mm x 120 mm (W x D x H)

Weight, tension meter:

1 kg

Weight, suction cup:

0.5 kg

*FS = Full Scale

2.1 Specifications

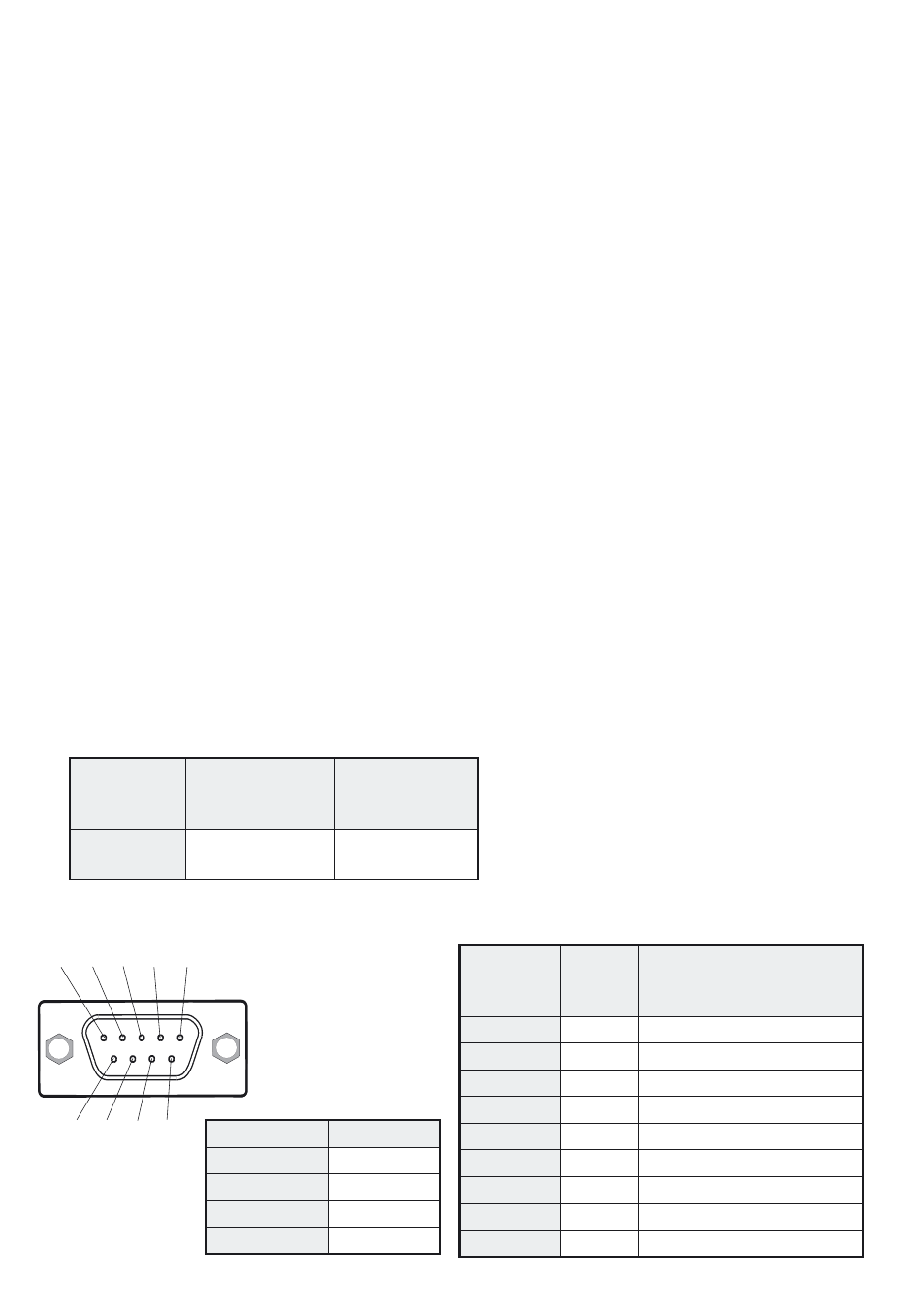

2.2 Pin Assignment and Signals of the RS-232 Interface (9-Pin D-Sub Connector)

Pin

Number Signal

Description

1

Not assigned

2

TXD

TRANSMITTED DATA

3

RXD

RECEIVED DATA

4

Not assigned

5

GND

Ground

6

Not assigned

7

RTS

READY TO SEND

8

Not assigned

9

2 V DC

Analog signal

Signal

RS-232-C

Data Bit

8 bits

Stop Bit

1 bit

Parity

None

Baud Rate

9600

V-grooved

Line Speed

m/min max.

Roller

Material

Standard

2000

Hardcoated

aluminium

5 4 3 2 1

9 8 7 6