6 verification of measuring accuracy, 7 calibration of the mst, E - 0 – Checkline MST User Manual

Page 16

16

3.6 Verification of Measuring Accuracy

All tension meters are calibrated with standard materials - such as polyamide monofila-

ment (PA) - according to the SCHMIDT factory procedure. Any difference in process ma-

terial size and rigidity from the standard material may cause a deviation of the accuracy. In

95% of all industrial applications the SCHMIDT calibration has been proven to provide the

best results and is used for comparative purposes.

Requirements:

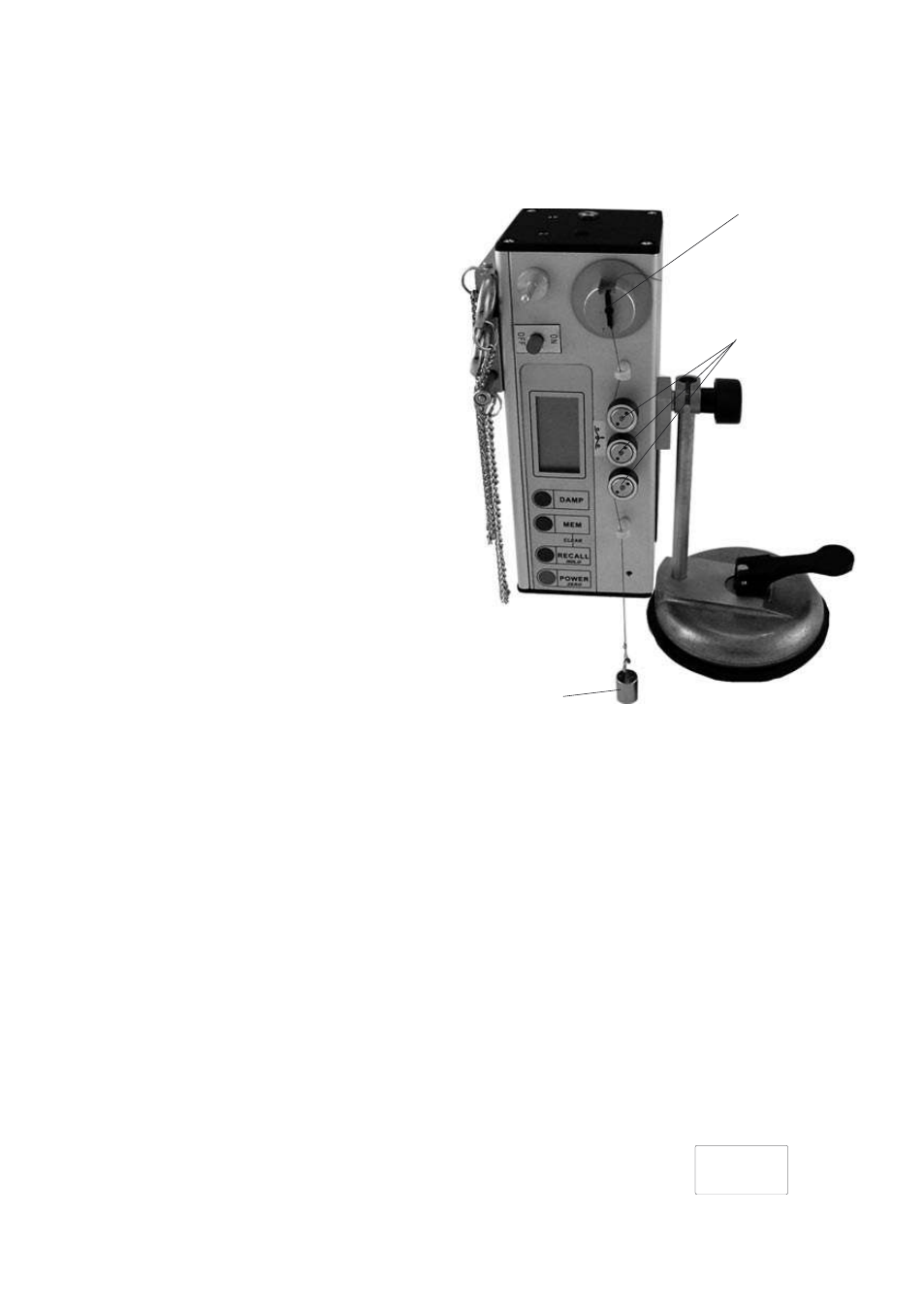

- The MST is factory calibrated for a verti-

cal material path (fig. 3.6).

The verification of accuracy must also be

carried out with a vertical material path.

Tension meter switched on as described

in Chapter 3.2.1.

- The required reference weight must be

provided.

- Hang a weight which corresponds to the

tension to be measured (pay attention to

the correct unit of measure) from the

measured material, vertically, as shown

here. The weight must hang freely, there-

fore, place the instrument near the edge

of the table, if necessary.

Verification procedure:

- Clamp the process material in the rub-

ber groove of the motor-driven DELIV-

ERY ROLLER and thread it through the

MEASURING ROLLERS.

The correct material path is indicated by

the red material path symbol on the front of the tension meter.

- The tension value shown on the DISPLAY should be equal to the value of the suspended

weight (pay attention to the measuring units).

If this procedure shows a deviation, you can recalibrate the instrument following the direc-

tions in Chapter 3.7.

3.7 Calibration of the MST

Requirements:

- The MST is factory calibrated for a vertical material path (fig. 3.6.).

Recalibration must also be carried out with a vertical material path.

- One cN weight each, corresponding to 10%, 50% and 90% of the tension range, must be

provided.

- No process material inserted.

- Tension meter switched off.

To select the calibration mode:

- Press and hold the MEM and POWER keys until the DISPLAY shows

E - 0

cN

.

- Release first the POWER key and then the MEM key.

MEASURING

ROLLERS

DELIVERY ROLLER

Weight

fig 3.6