Checkline TI-25M User Manual

Page 9

– 9 –

4 .0

G

ET T I N G

S

TART ED

4.1 Connecting The Probe

Grasp the connector located at the end of the probe cable and carefully

insert the connector plugs into the receptacle located at the top edge of the

gauge. Make sure the connector is fully inserted into the receptacle. The

orientation of the plugs does not matter as they are non-polarized.

4.2 Turn On The Power

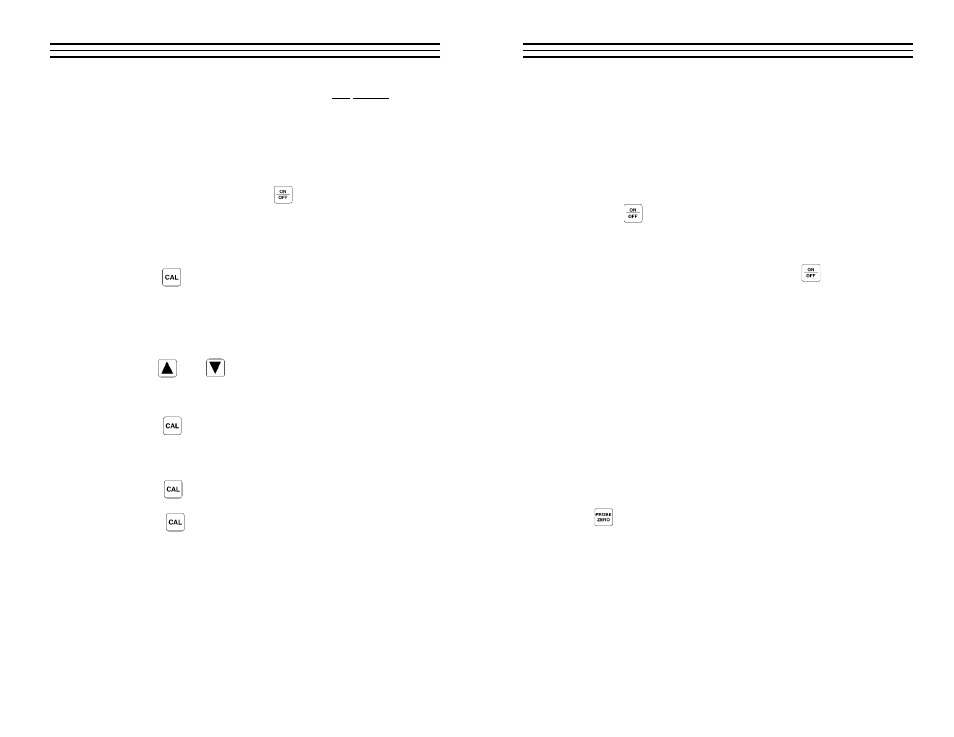

Press the key. All of the LCD Display elements will momentarily

illuminate. The firmware revision will then be momentarily shown

(for factory troubleshooting purposes only). Eventually the display will

show “0.000” (or “0.00” if using metric units), indicating it is ready for use.

Note: 1. The gauge is turned off by pressing the key again.

2. The gauge will automatically power off after 5 minutes of

non-use.

3. All settings will be retained in non-volatile memory.

4.3 “Zeroing” The Probe

The Probe Zero Plate is used to “zero” the probe for calibration purposes.

Normally, this procedure is required only when the probe is connected to

the instrument for the first time, but since this process takes less than 10

seconds, we recommend performing the Probe Zero function occasionally

as described below.

1. Check that the probe face (wear surface) is clean and free of debris.

2. Place a small drop of the supplied coupling fluid on the built-in

Probe Zero Plate located on the top of the gauge.

3. Press the probe firmly against the Plate.

4. The Stability Indicator on the LCD display should have six or

seven bars illuminated and a value should be shown in the display.

5. While maintaining probe contact with the Test Plate, press the

key. The display will show “Prb0” while the TI-25M

calculates its zero point.

Note:

The value shown on the display can be recorded and used in the

future to confirm that the gauge is functioning properly.

– 16 –

6.3 Changing Calibration - Acoustic Velocity Is Not Known

In applications where the type of material is not known or the material is

not listed in the Acoustic Velocity Table, the following procedure can be

used to calibrate the gauge for highest accuracy.

1. Obtain a sample of the material with a known thickness or use a

micrometer, caliper or similar device to accurately measure it.

2. Turn on the gauge by pressing the key.

3. Place a small amount of coupling fluid on the sample of known

thickness and place the probe on the sample. The Stability Indicator

should have nearly all its bars illuminated. Having achieved a stable

reading remove the probe from the sample.

4. Press the key.

5. The units of measure indicator “IN” or “MM” will be flashing

indicating that you are in the Measurement Calibration mode.

(The other calibration mode is the Acoustic Velocity Calibration mode,

as described in section 6.2, which is used to adjust the acoustic

velocity to another known value.)

6. Use the and keys to adjust the displayed measurement

value to match the thickness of the known sample. By pressing and

holding the key, the numbers will change more rapidly.

7. Press the key again and the acoustic velocity units indicator

“IN/µs” or“M/s” will be flashing showing the acoustic velocity

value that was calculated for this sample. If desired, record this

value so it can be re-entered easily in the future.

8. Press the key again to exit the calibration mode and return to

the measurement mode.

Note: If the key is pressed while in the calibration mode, the

TI-25M will be reset to the factory default calibration for common steel

(0.2330 IN/µs or 5920 M/s).