Checkline TI-25M User Manual

Page 11

– 11 –

– 14 –

Extremely rough surfaces such as the “pebble-like” finish of some cast

irons, will prove most difficult to measure. These kinds of surfaces act on

the sound beam like frosted glass acts on light; the beam becomes diffused

and scattered in all directions.

Rough surfaces also contribute to excessive wear of the probe, especially in

applications where the probe is “scrubbed” along the measurement surface

for use in the Scan mode. The probe should be inspected regularly for signs

of uneven wear on the probe surface (wearface). If this is detected, the

probe should be returned to the factory for repair or replacement.

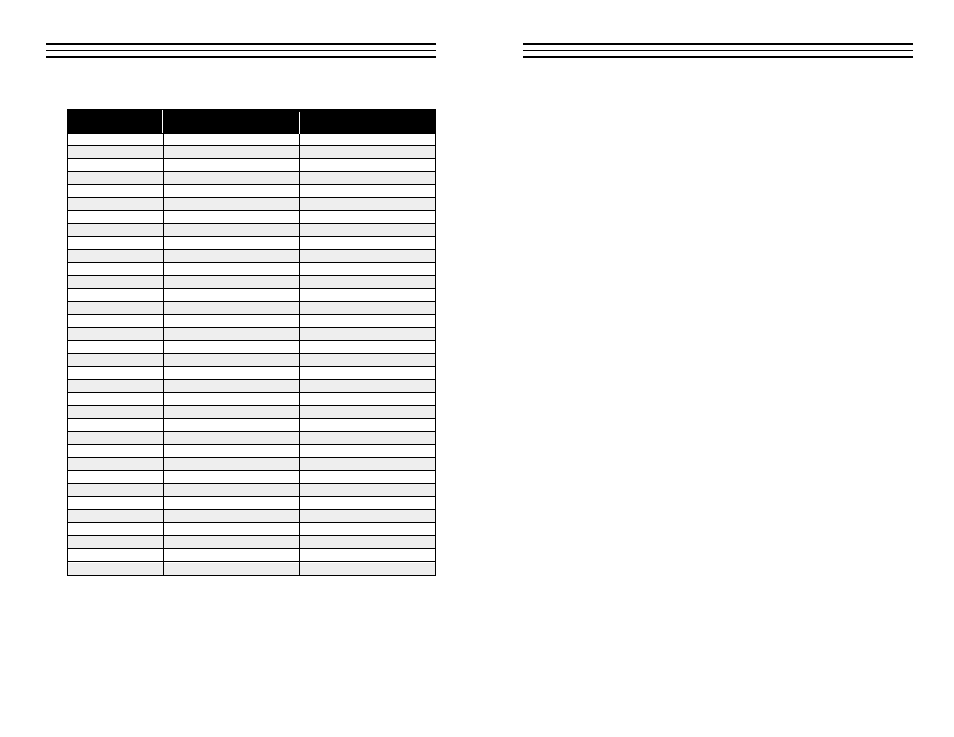

6.1 Acoustic Velocity Table

Aluminum

0.2500 6350

Bismuth 0.8600

2184

Brass 0.1730

4394

Cadmium 0.1090 2769

Cast Iron

0.18000

4572

Constantan 0.2060

5232

Copper 0.1840 4674

Epoxy resin

0.1000

2540

German silver

0.1870

4750

Glass, crown

0.2230

5664

Glass, flint

0.1680

4267

Gold 0.1280

3251

Ice 0.1570

3988

Iron 0.2320

5898

Lead 0.8500

2159

Magnesium 0.2280

5791

Nickel 0.2220

5639

Nylon 0.1020

2591

Paraffin 0.0870 2210

Platinum 0.1560 3962

Plexiglass 0.1060 2692

Polystyrene 0.0920

2337

Porcelain 0.2300 5842

PVC

0.0940 2388

Quartz glass

0.2220

5639

Rubber, vulcanized

0.0910

2311

Silver

0.1420 3607

Steel, common

0.2330

5920

Steel, stainless

0.2230

5664

Stellite 0.2750

6985

Tin 0.1310

3327

Titanium 0.2400 6096

Tungsten 0.2100 5334

Zinc 0.1660

4216

Material Velocity Velocity

Type Inches/µs

Meters/s

Notes: 1. These values are to be used only when a suitable sample of known thick-

ness is not available for calibrating, as slight variations in material

composition, finishing (hardening, polishing, etc.) or shape can affect the

accoustic velocity.

...

Notes:

2. “✔ ”denotes the factory default setting for acoustic velocity.

✔