Checkline TI-25M User Manual

Page 8

– 8 –

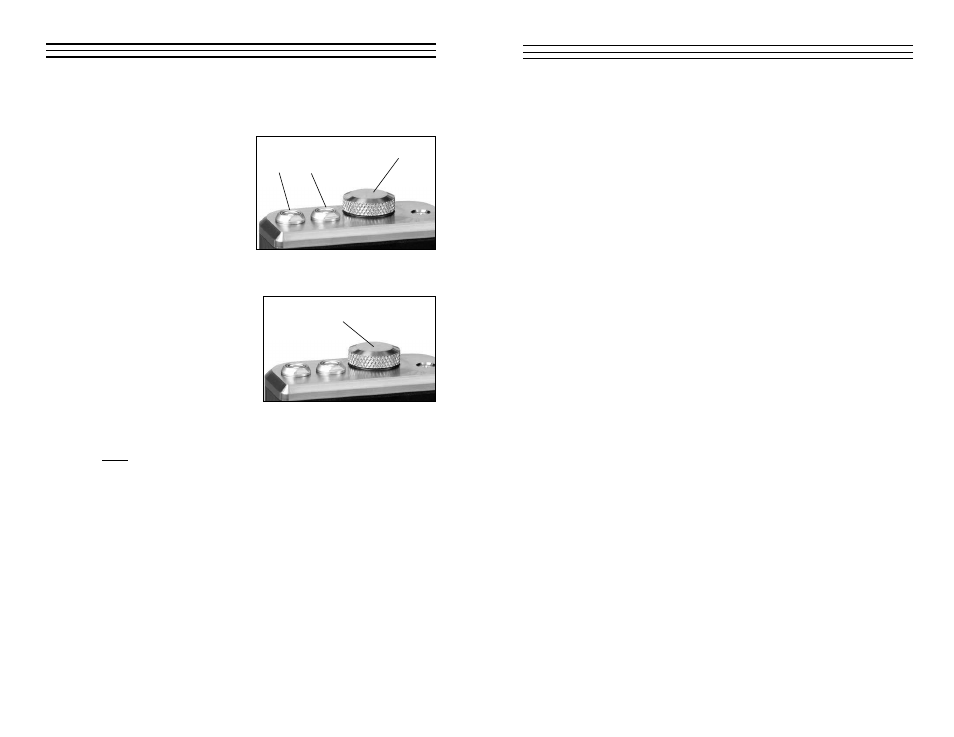

3.7 Probe Connector Receptacle

Located on the top edge of the TI-25M housing are the receptacles for the

probe and the probe zero plate.

The connectors for the probe

are non-polarized so the con-

nector at the end of the probe

cable can be inserted into

this receptacle in either

orientation. Make sure the

connector is “well seated” in

the receptacle.

3.8 Battery Compartment (Changing The Battery)

The battery compartment is

located under the probe zero

test plate. To open the battery

compartment, unscrew the

probe zero plate by rotating it

counterclockwise. The TI-25M

operates on two (2) AA

Batteries (1.5 V). If desired,

rechargeable batteries may be

used.

The TI-25M is shipped with the batteries installed. Insert batteries in the

polarity indicated on the rear label.

Note: When the display elements begin to flash off and on repeatedly, the

batteries are low and should be replaced.

Battery Cover

Probe Receptacles

Probe Zero

Plate

– 17 –

6.4 Changing Calibration — Two-Point Calibration Procedure

NOTE: This procedure requires two samples with "known" thickness

values are available during this calibration. The two samples should be at

the high and low portions of the expected range thickness that will be

encountered.

1. Turn on the gauge

2. Perform a Probe-Zero (refer to Section 4.3).

3. Apply couplant to the sample piece.

4. Press the transducer against the sample piece, at the first/second

calibration point, making sure that the transducer sits flat against

the surface of the sample. The display should show some (probably

incorrect) thickness value,and the Stability Indicator should have nearly

all its bars on.

5. Having achieved a stable reading, remove the transducer. If the

displayed thickness changes from the value shown while the transducer

was coupled,repeat step 4.

6. Press the CAL key. The IN (or MM) symbol should begin flashing.

7. Use the UP and DOWN arrow keys to adjust the displayed thickness up

or down, until it matches the thickness of the sample piece.

8. Press the PROBE-ZERO key. The display will flash 1OF2. Repeat

steps 3 through 7 on the second calibration point.

9. Press the PROBE-ZERO key again and the display will now show the

sound velocity value it has calculated based on the two known thickness

values that were entered.

10. The guage is now ready to perform measurements within this range on

that material.